Reinforcing steel bar connecting brick wall stud structure

A technology of pilasters and steel bars, which is applied in building maintenance, construction, building construction, etc., can solve the problems that are not ideal, that new and old brick pilasters cannot produce occlusal effects, and cannot form an integrated joint work reinforcement effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

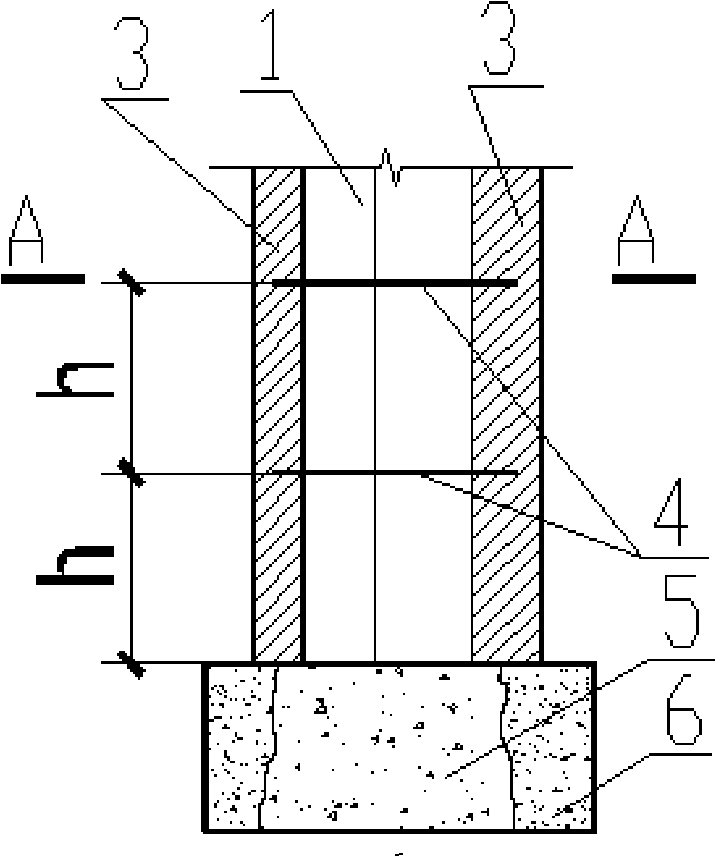

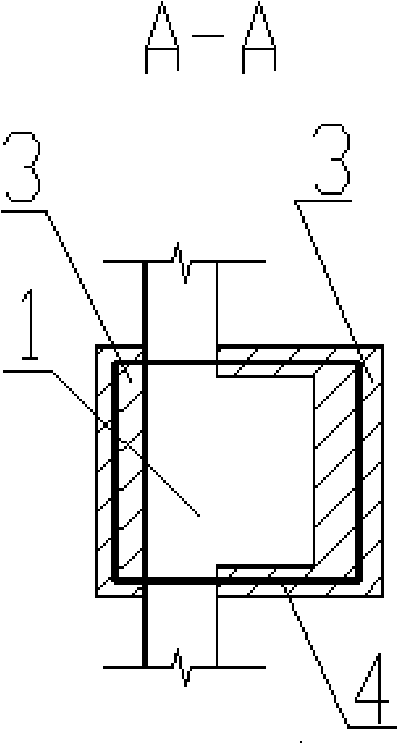

[0011] Embodiments of the present invention: when adopting the present invention to reinforce brick pilasters, it can be carried out as follows:

[0012] First, the total area of the required brick pilaster is determined by calculation, and the difference obtained by subtracting the area of the original brick pilaster 1 is the area of the pilaster that needs to be increased, that is, the area of the newly added peripheral brick cover 3;

[0013] The second is to pour the plain concrete strip foundation required after the newly added brick pilaster is the new foundation 6. Before pouring, the edges of the plain concrete strip foundation 5 of the original brick pilaster 1 should be roughened to facilitate the new and old foundations. The foundation is better connected;

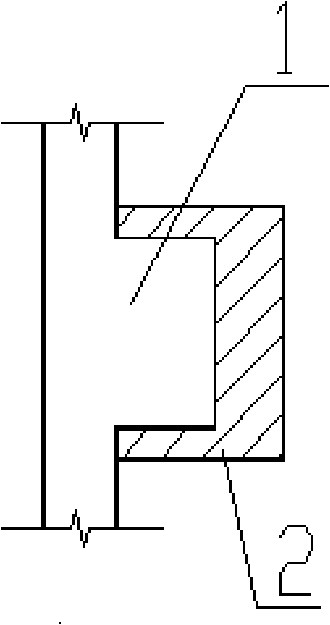

[0014] Thirdly, on both sides of the original brick pilaster 1 at a distance of 60mm from the outer skin of the brick pilaster, at intervals of 6 to 8 skin brick thicknesses along the height direction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com