Flotation recovery rate prediction method based on image characteristic analysis

A flotation recovery rate and image feature technology, which is applied in the analysis of materials, material analysis by optical means, measurement devices, etc., can solve the problems that the recovery rate cannot be detected online and cannot be accurately predicted, and can solve the problem that the recovery rate cannot be detected online. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

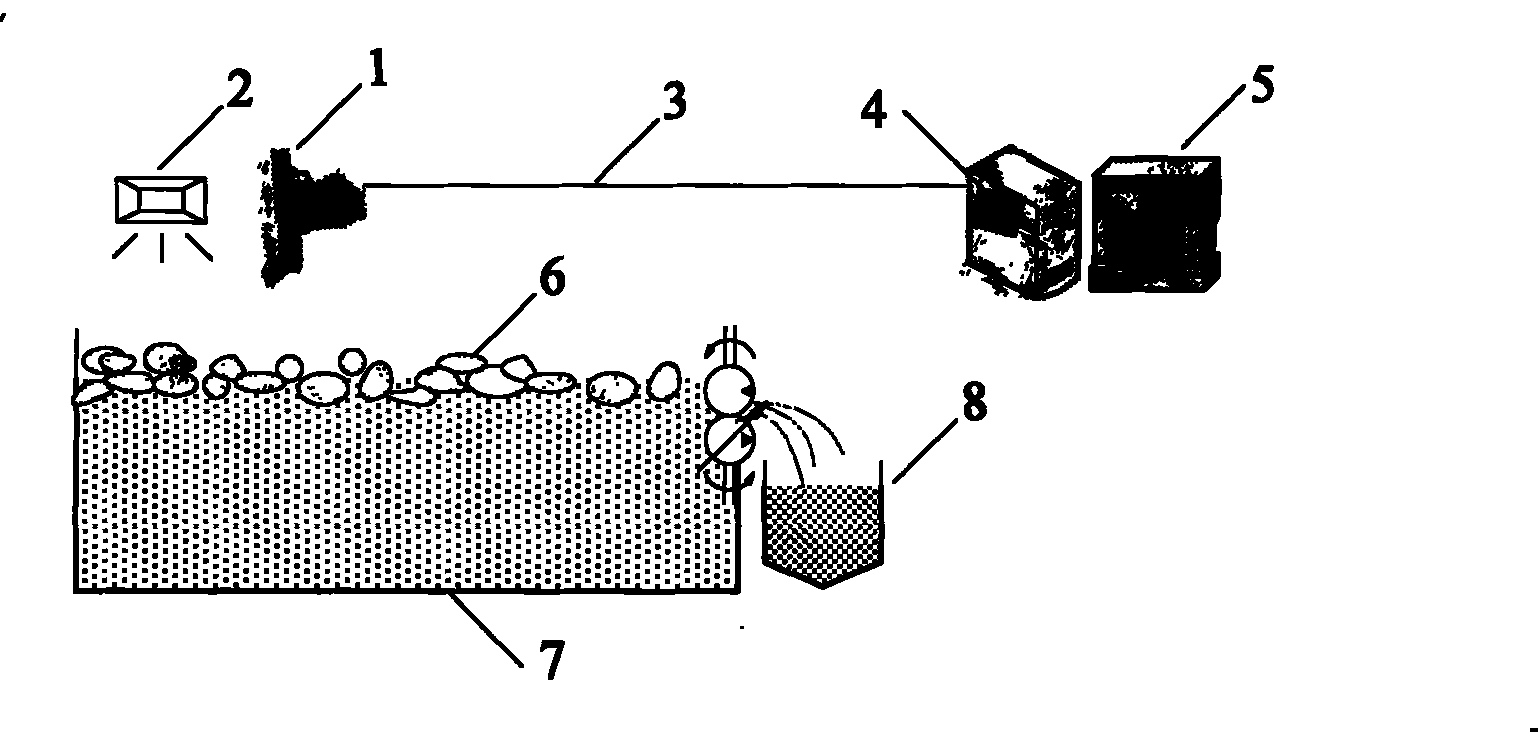

[0010] The hardware structure of the foam image analysis system is as follows: figure 1 As shown, it is mainly composed of a camera 1, a light source 2, an optical fiber 3, an image acquisition card 4, and a computer 5. In the figure, the camera 1 is used to photograph the foam layer 6, and is installed vertically directly above the flotation tank 7, with a distance of 200 cm from the overflow tank 8.

[0011] The resolution of camera 1 is set to 1024×768, the shutter is set to 323uS, the working distance is 110cm, the focal length of the lens is 55mm, the field of view is 16cm×12cm, powered by 12V DC power supply, and the measurement accuracy is 6.4-6.8pixels / mm.

[0012] The light source 2 uses a 200W high-frequency fluorescent lamp, the color temperature is 4500K, the power supply is 220V@50HZ, the light source 2 is close to the camera 1, and the horizontal distance is 10cm.

[0013] The color CCD camera 1 acquires the image of the foam layer, digitizes the video signal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com