Novel steel-ball punch needle type atomizing pump spray-head nozzle device

A steel ball punching needle type and spray pump technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of product accuracy not meeting product requirements, poor machine sealing, and nozzles not hitting in place, etc., to achieve Good sealing, high working efficiency, and enhanced mechanical service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

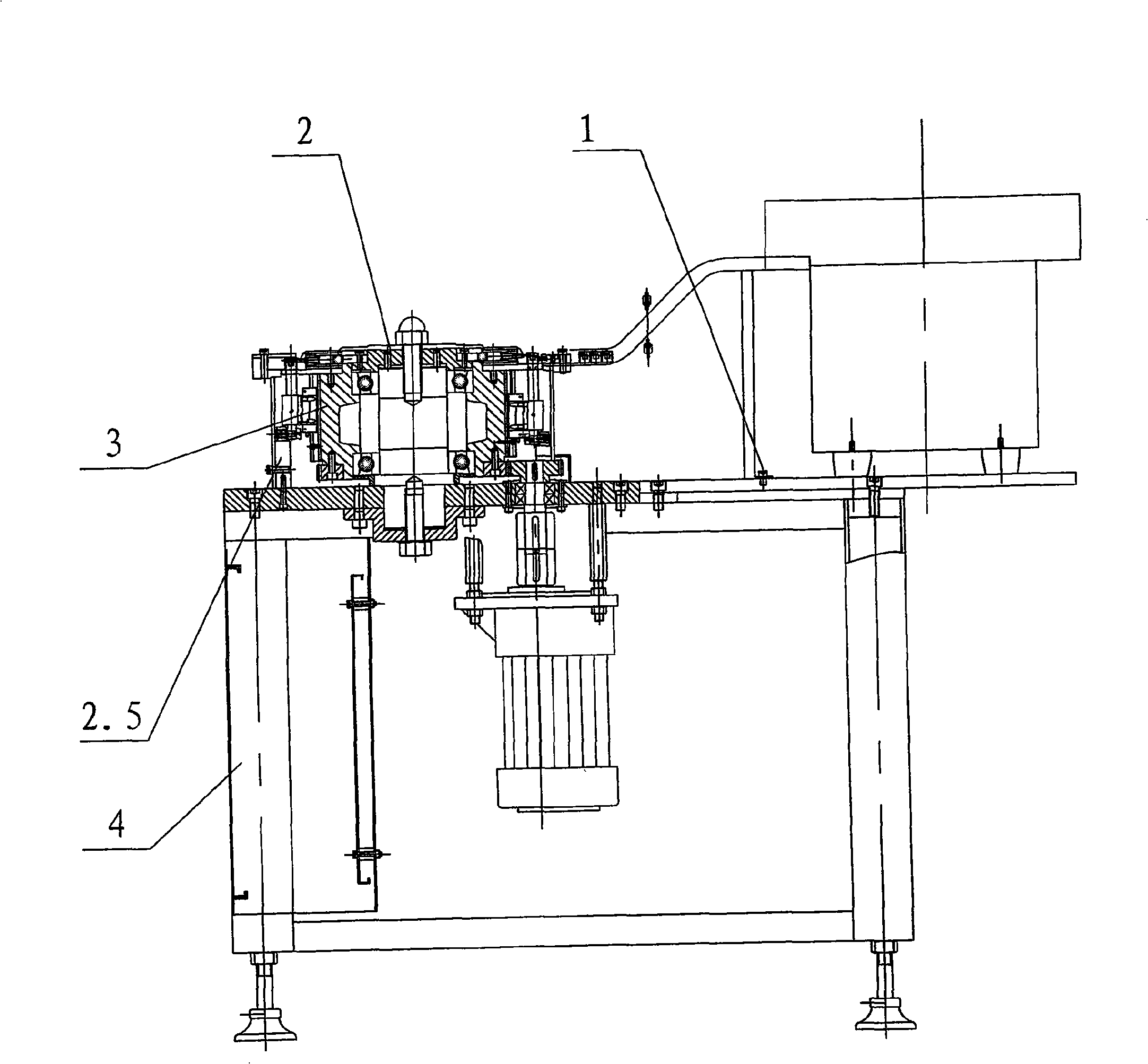

[0022] see figure 1 , Novel steel ball punching pin type spray pump nozzle that the present invention relates to hits the nozzle machine, mainly is made up of frame 4 and the feeding device 1 that is installed on the frame 4, raised rail swivel seat device 2 and turntable cam device 3.

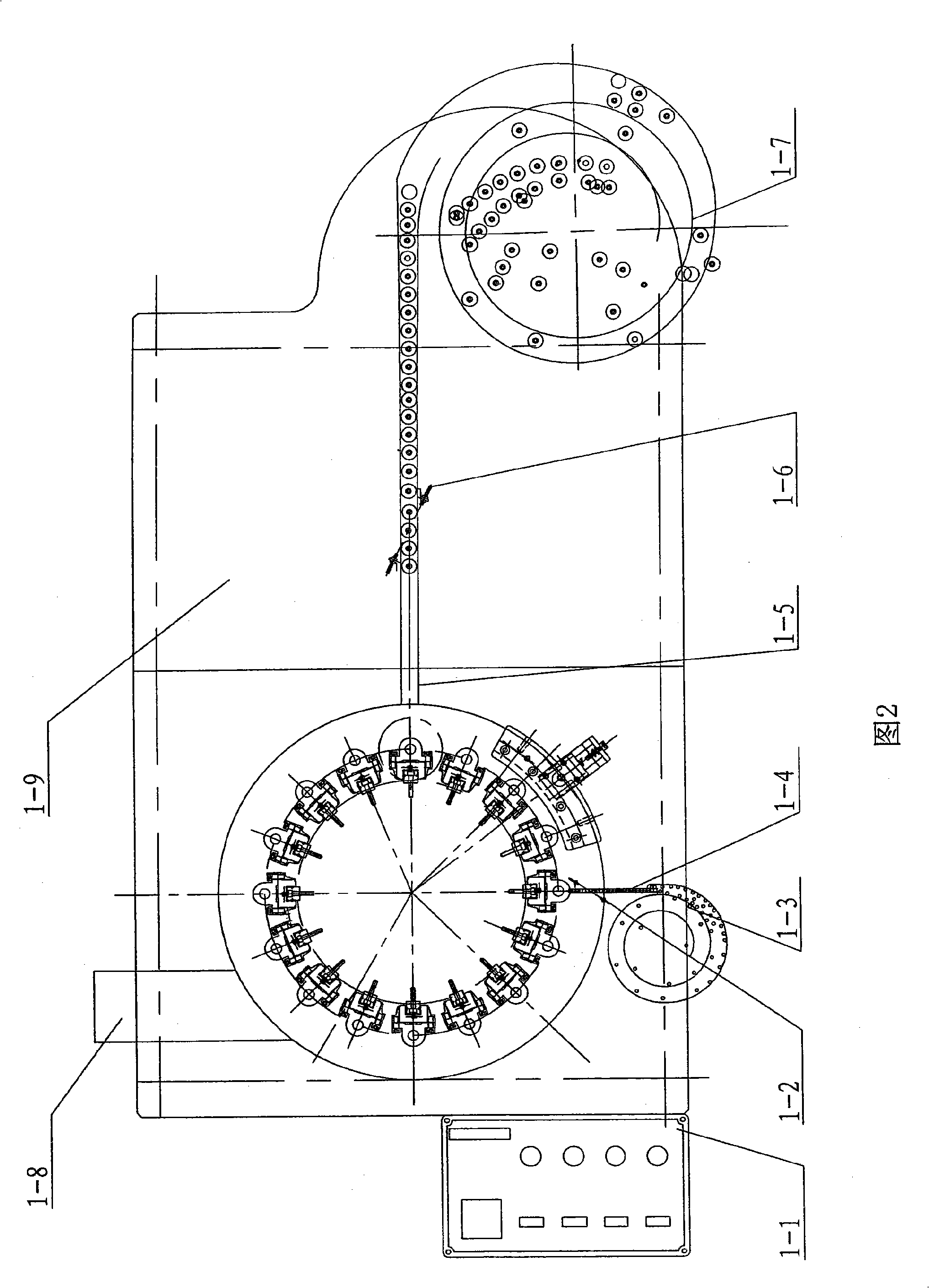

[0023] Referring to Fig. 2, the feeding device 1 is mainly composed of a panel 1-9, a nozzle vibration feeder 1-7, a nozzle feeder 1-5, an optical fiber sensor 1-6 controlling the nozzle feeder, and a nozzle vibration feeder 1- 3. Nozzle feeder 1-4, optical fiber sensor 1-2 for controlling the nozzle feeder, finished product discharge port 1-8 and electric control box 1-1. The nozzle vibration feeder 1-7, the nozzle feeder 1-5, the optical fiber sensor 1-6, the nozzle vibration feeder 1-3, the nozzle feeder 1-4, the optical fiber sensor 1-2 and the finished product outlet 1-8 are all ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap