Pre-mixed abrasive high pressure water-jet system rotary pipe joint structure

A technology of high-pressure water jet and pre-mixed abrasives, which is applied in drilling pipes, casings, drilling with liquid/gas jets, etc., can solve problems such as seal leakage, and achieve the effects of improving working life, stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

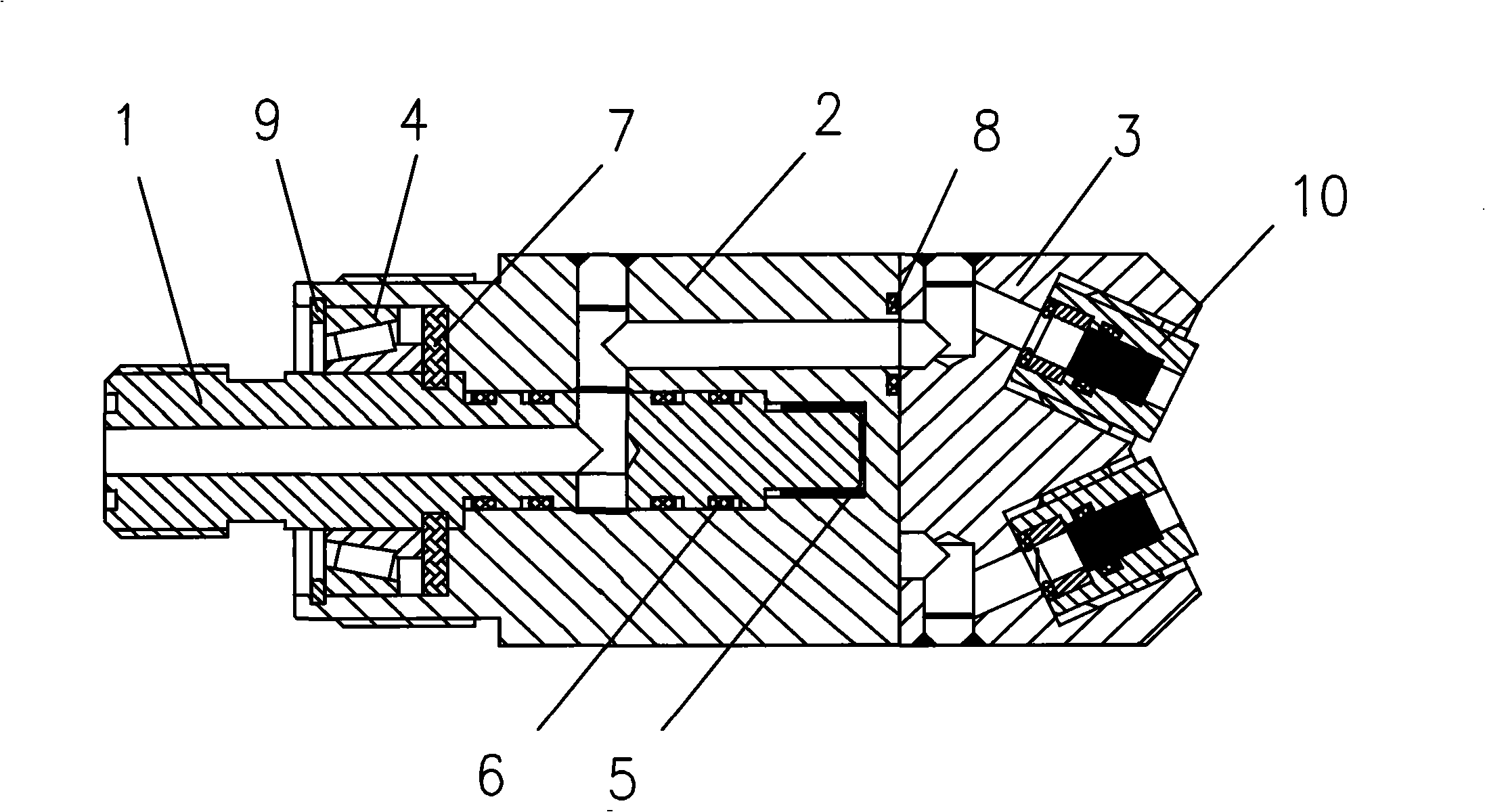

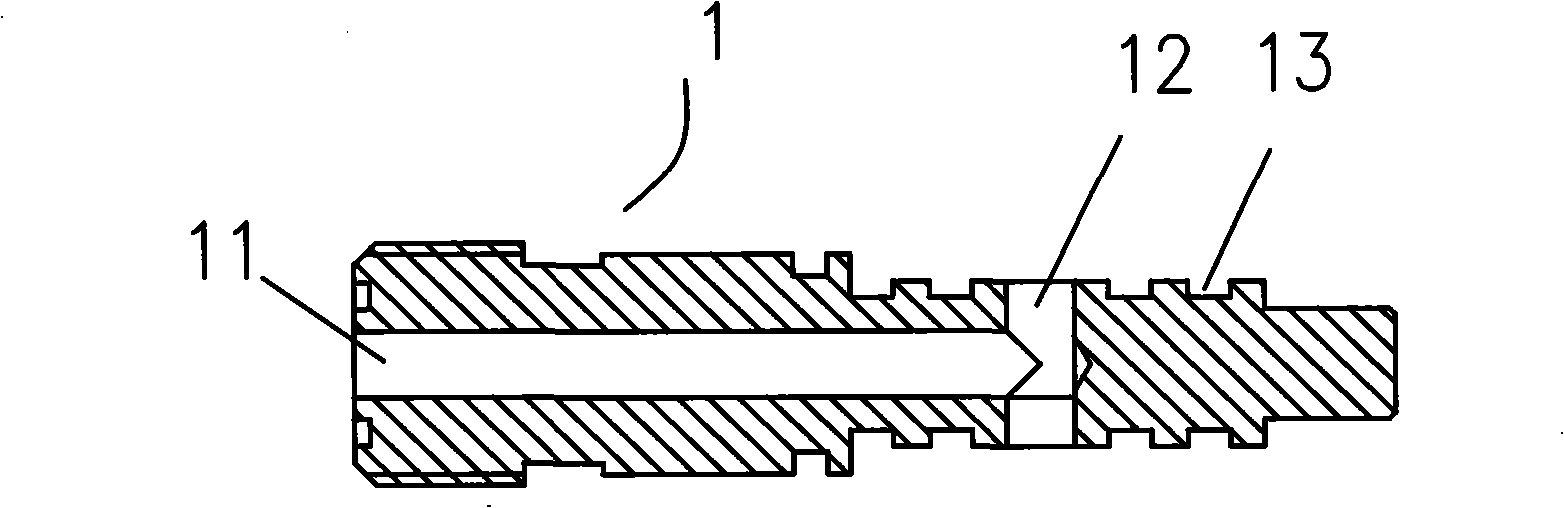

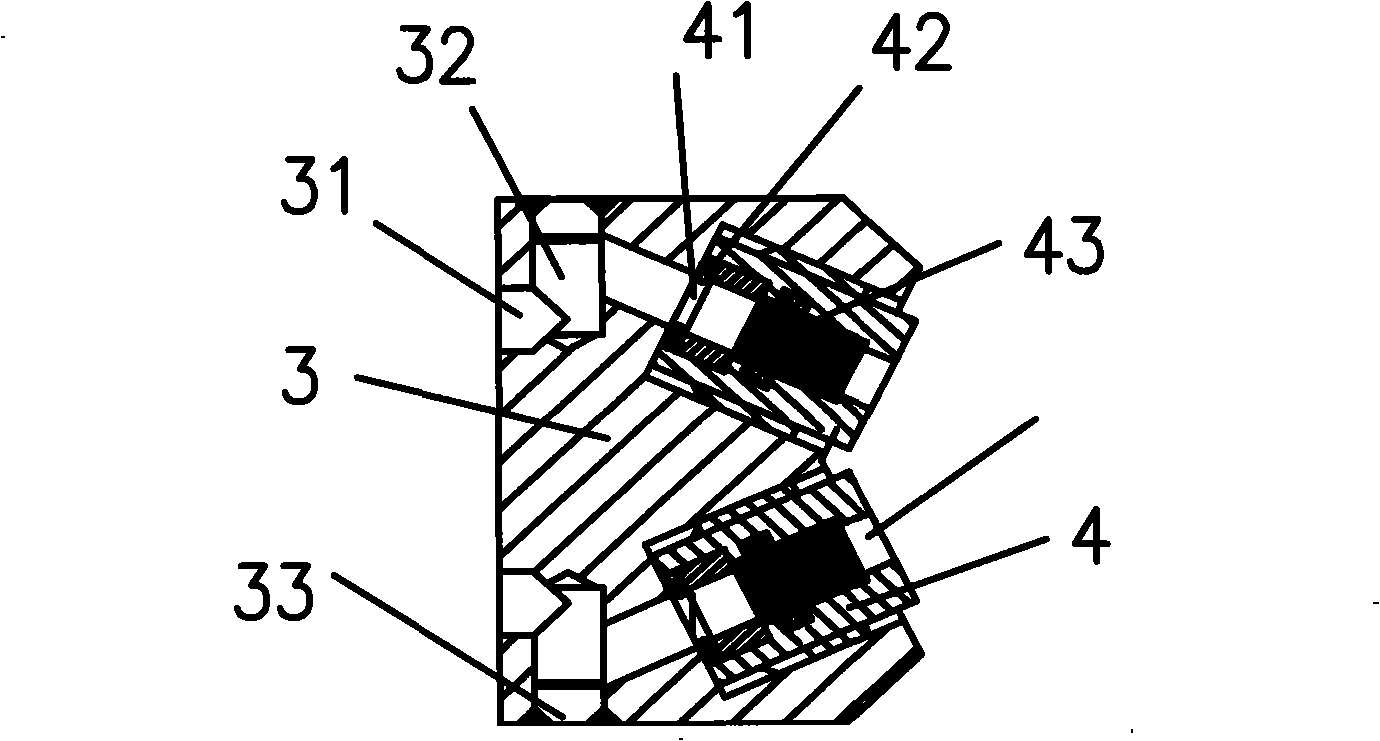

[0020] Such as figure 1 As shown, it includes a hose joint 1, a joint body 2, and a rear cover 3. The rear cover 3 and the joint body 2 are fixedly connected by bolts, and a sealing ring 8 is provided at the joint. The front end of the hose joint 1 is processed with an external thread for installing a high-pressure hose. A vertical water outlet 12 is opened in the middle of the hose joint 1. The vertical water outlet 12 communicates with the inner water inlet 11. In the hose joint 1 Both sides of the vertical water outlet 12 are respectively provided with two annular grooves 13, see figure 2 As shown, a sealing ring 6 is respectively installed in the annular groove 13, the joint body 2 and the hose joint 1 are connected by bearings, the inner part is the second composite bearing 5, the outer part is the first bearing 4, and the water inlet of the joint body 2 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com