Piezoresistive strain gauge using doped polymeric fluid

A strain gauge and piezoresistive technology, applied in the field of strain gauge and its manufacturing, can solve problems such as environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

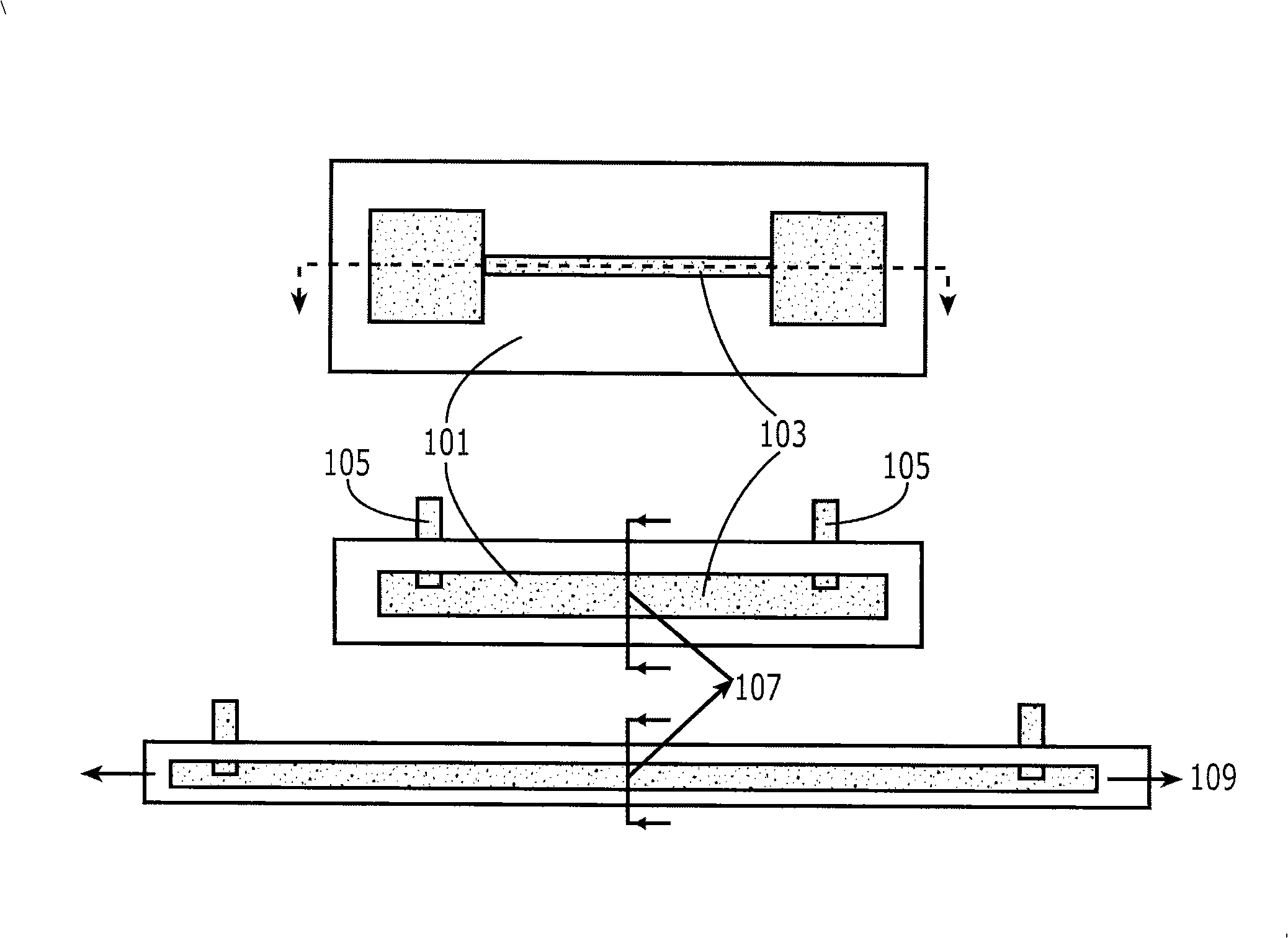

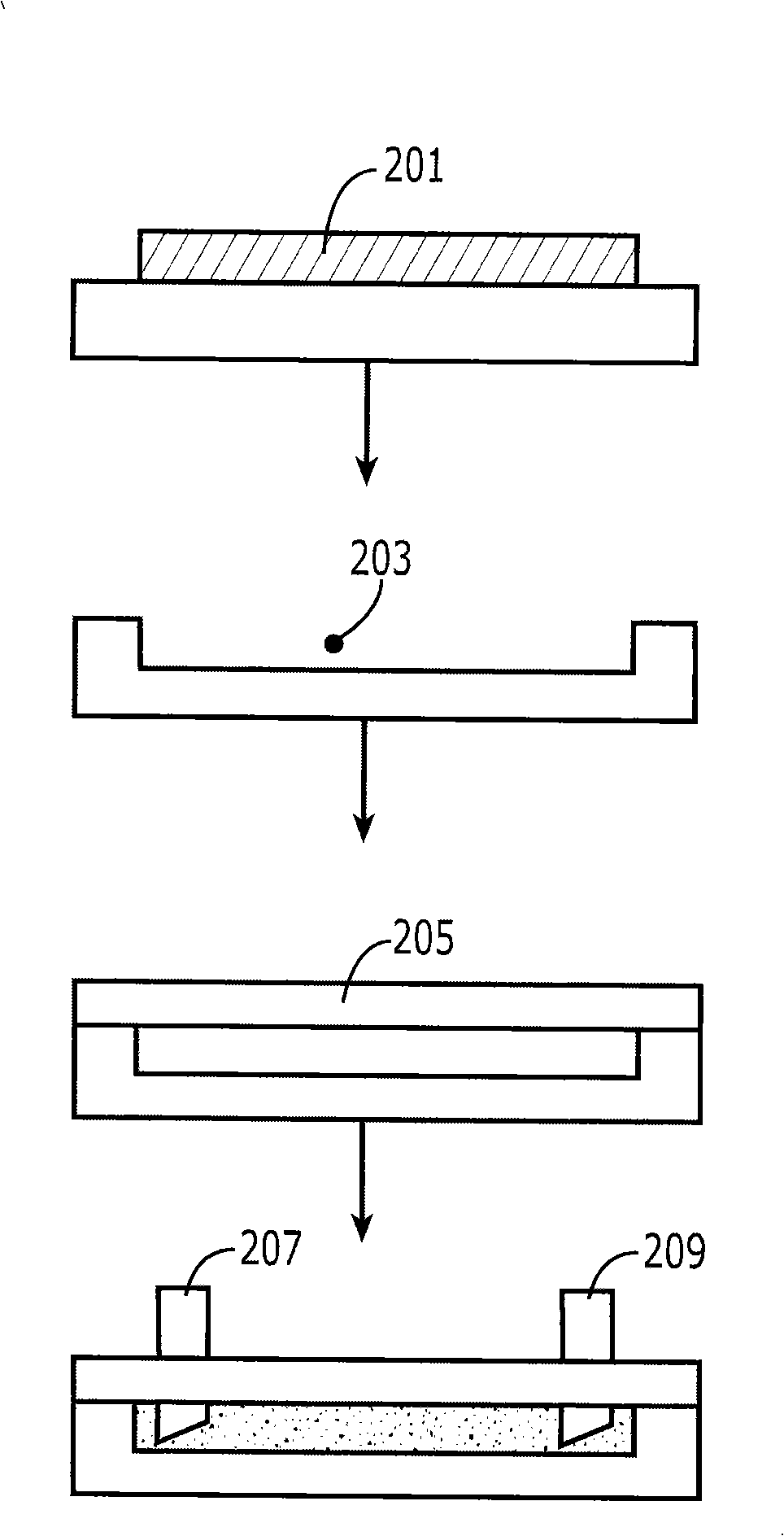

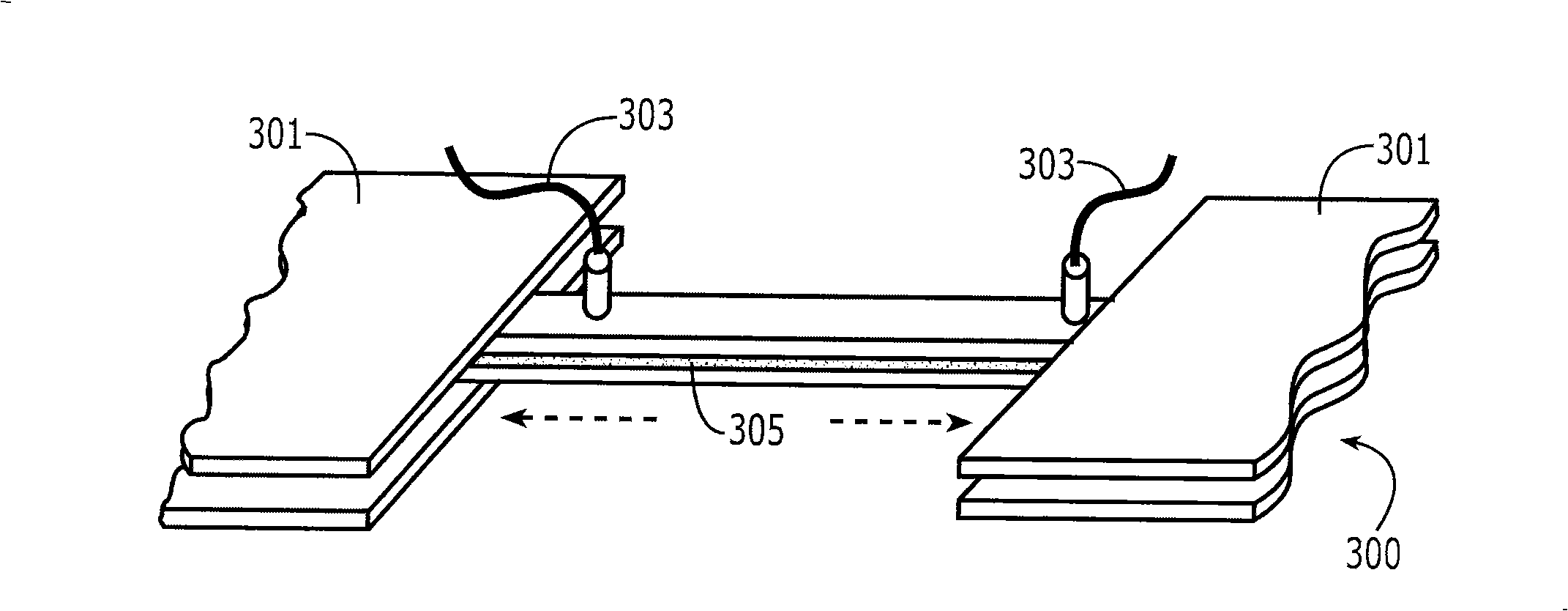

[0037] The strain gauge of this example is made by encapsulating conductive silicone oil and metal electrodes with two layers of polydimethylsiloxane (PDMS) films. PDMS (Dow Corning Sylgard 184) was prepared by mixing curing agent and elastomeric substrate at a mixing ratio of 1:10. First, coat a thin layer of the PDMS mixture on a silicon wafer and then degas it in a vacuum chamber for 15 min. It was then cured in an oven at 70°C for 1 hour. The thickness of PDMS was measured to be about 500 μm. By mixing 10~30wt% CDX-7055 into silicone oil (Columbian Chemicals, Co. produced) carbon black powder or carbon nanotubes to obtain conductive silicone oil. First connect a pair of metal wires to one side of the silicon wafer to make the electrodes that make contact with the strain gauge material. Conductive silicone oil was applied by screen printing or embossing on the PDMS membrane with designed openings on the preformed PDMS membrane. Pour a layer of PDMS mixture over conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com