Method for operating a warp knitting machine and warp knitting machine

An operating method and technology of warp knitting machines, applied in the field of warp knitting machines, can solve problems such as increased noise emission, production capacity limitation, etc., and achieve the effect of increasing mechanical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

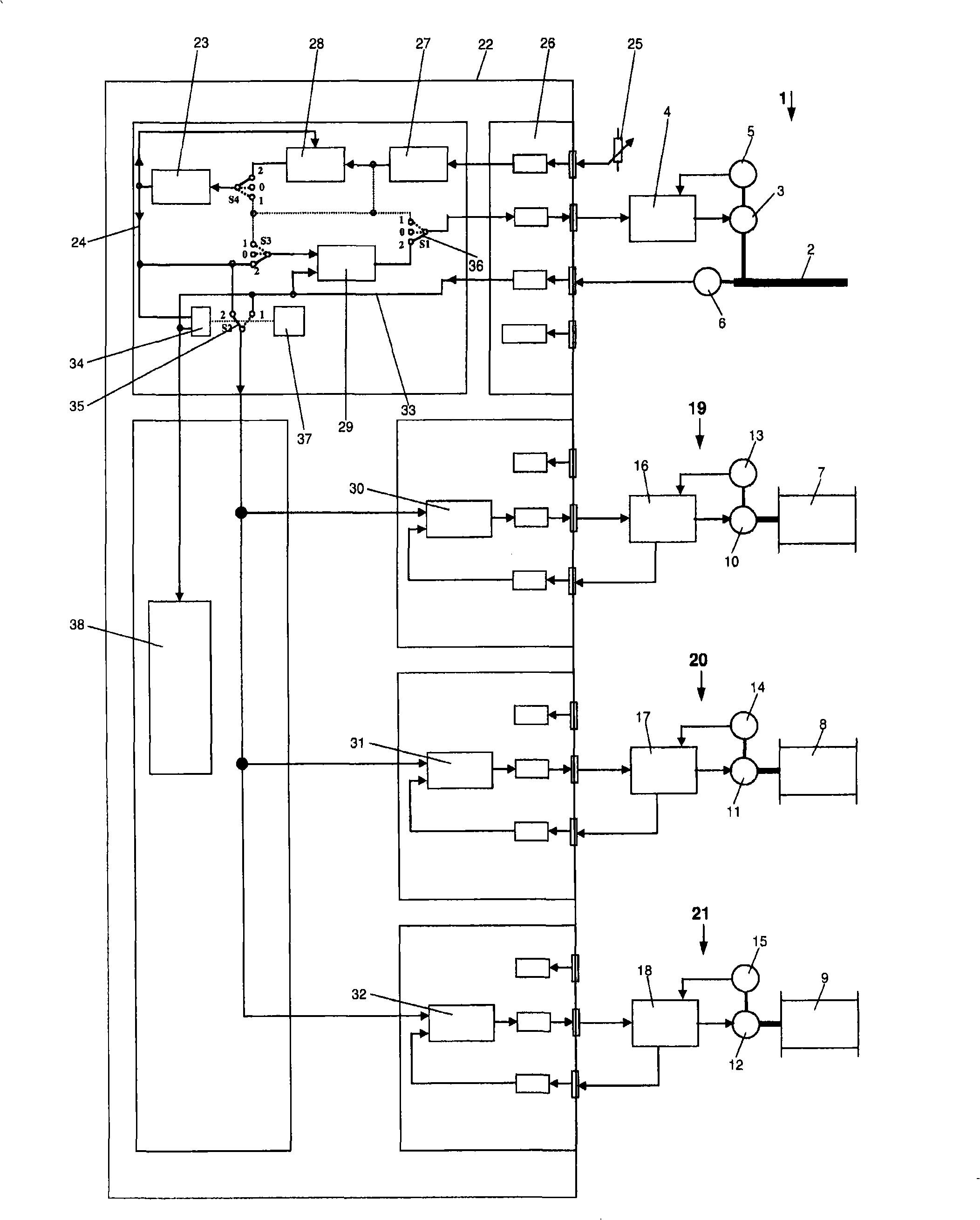

[0029]A warp knitting machine 1 shown only in general terms has a spindle 2 which is driven by a spindle drive 3 . The spindle drive 3 is controlled by a drive amplifier 4 . The drive amplifier 4 is in turn connected to an angle encoder 5 which constantly determines the rotational angle position of the spindle drive 3 .

[0030] The spindle 2 is likewise connected to an angle encoder 6 which continuously determines the rotational angular position of the spindle.

[0031] The warp knitting machine 1 also has a number of follower drives 19-21 for controlling the movement of the pattern bars or beams, for example. Three such follower drives 19-21 are shown here by way of example, the respectively driven elements are simply referred to as "follower shafts" 7-9. Each follower shaft 7-9 is driven by a motor 10-12. Each motor 10-12 is connected to an angle encoder 13-15, which in turn transmits the current angular position of the motor 10-12 to the drive amplifier 16-18. The driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com