Double layer mixing structure carbon nano tube membrane field emission cathode and preparation thereof

A field emission cathode and carbon nanotube technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of reducing contact resistance, increasing the enhancement factor of unfavorable CNT emitters, and increasing CNT and substrate Contact resistance and other issues to achieve the effect of increasing the enhancement factor, improving the field emission performance, and reducing the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific process includes the following two steps:

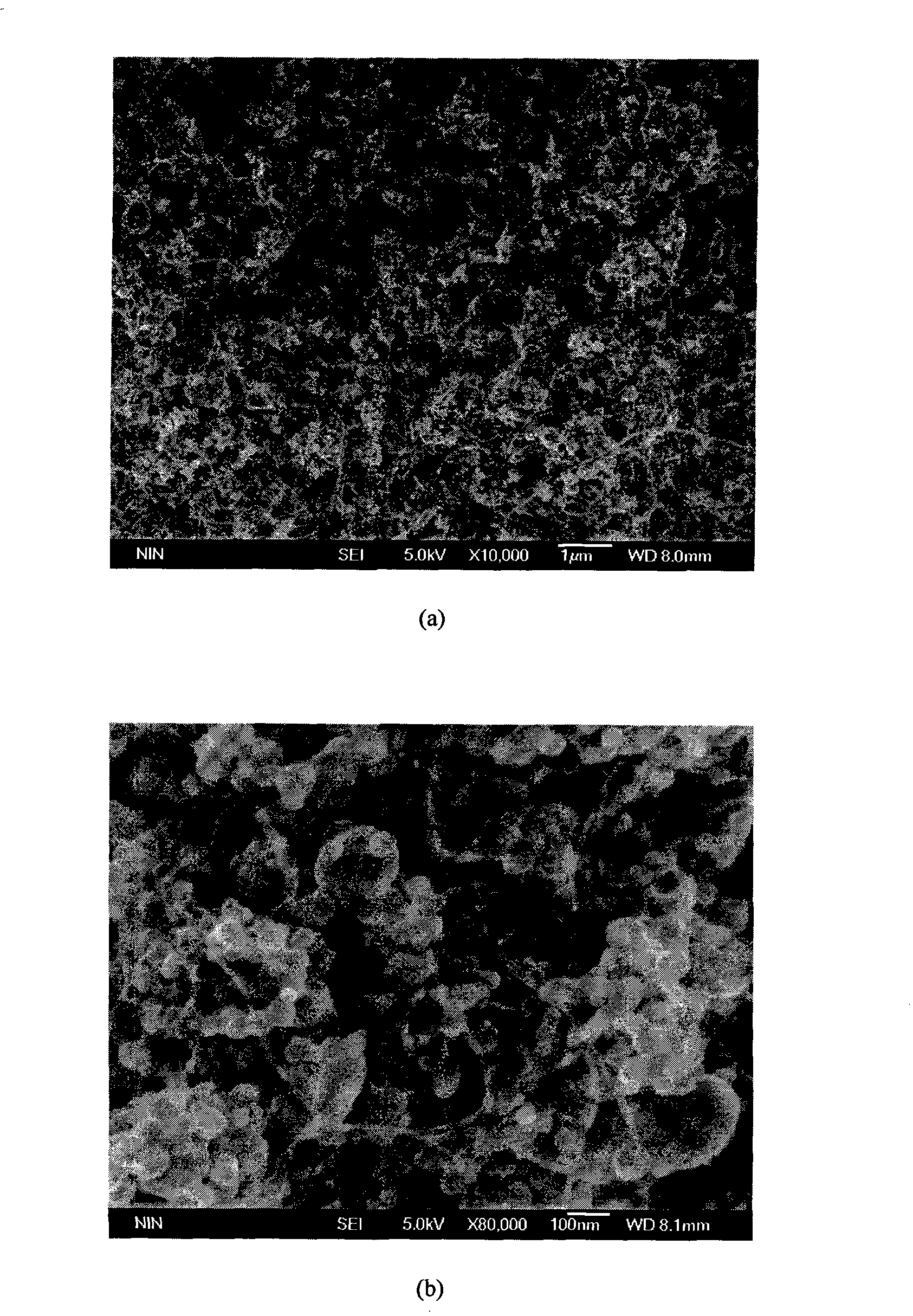

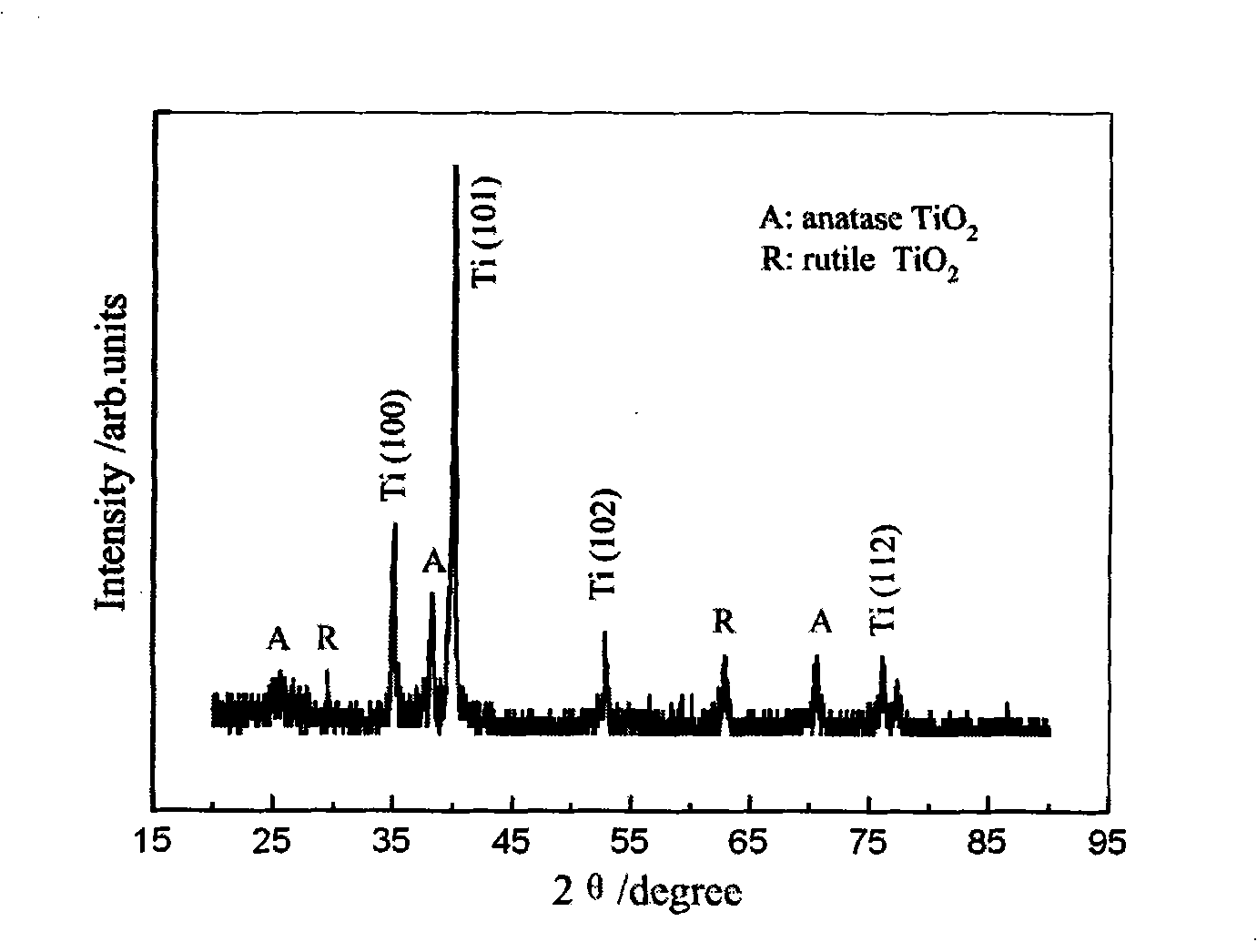

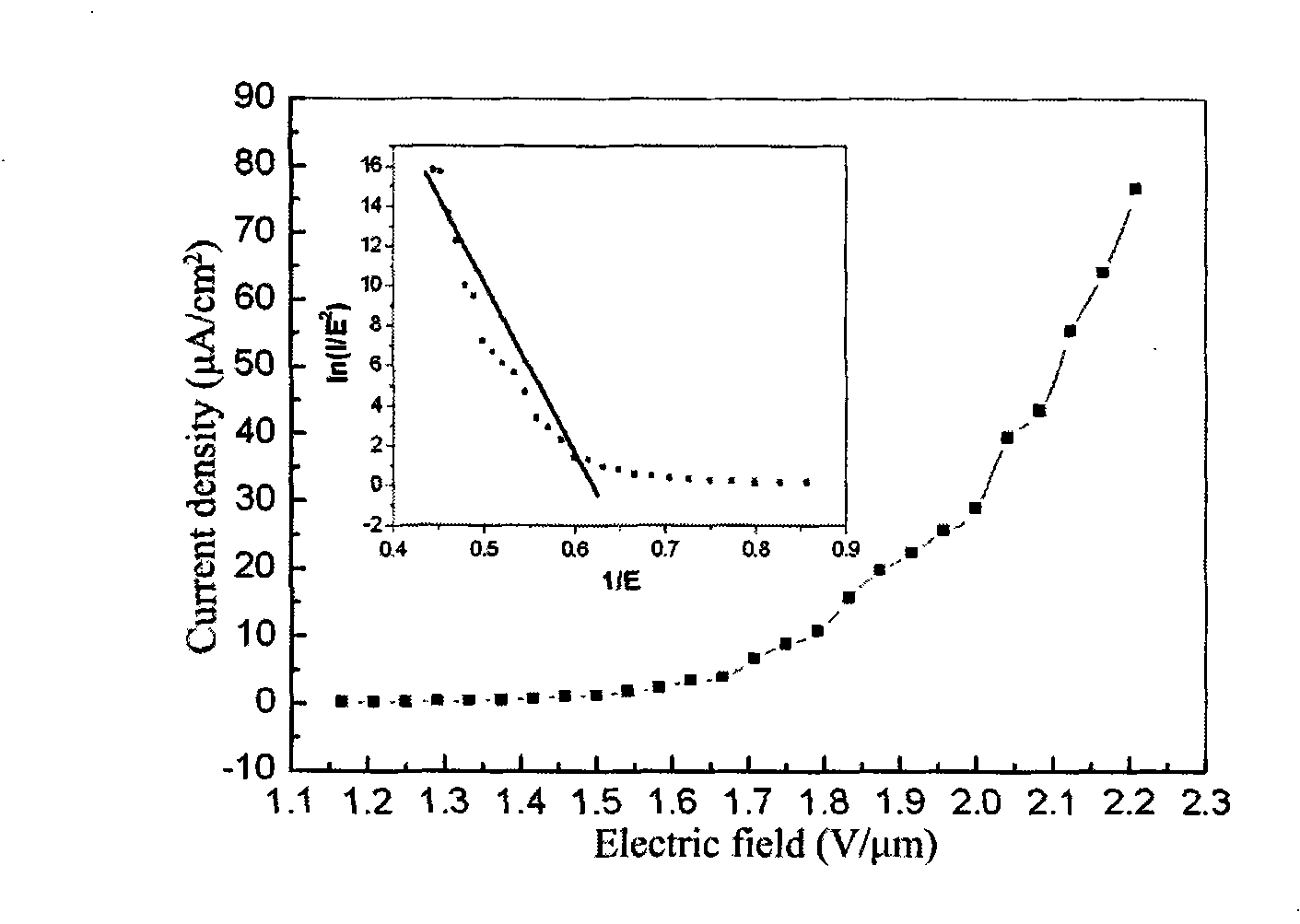

[0027] The first step is to prepare a CNT composite cathode film with a single-layer Ti-blended structure. 1. Put the multi-walled CNT into a mixed solution of nitric acid and sulfuric acid (volume ratio: 4:1) for acidification, remove amorphous carbon and catalyst, wash with deionized water, filter with filter paper and dry in a drying oven. 2. Timely disperse CNTs into terpineol with an ultrasonic wave length, filter through a screen to remove larger aggregates; add ethyl cellulose, heat to 100°C with a magnetic stirrer and stir for a long time until the ethyl cellulose All the elements are dissolved to form a uniform dispersion, that is, CNT slurry; the nano-Ti powder slurry is prepared by the same method. 3. Mix the CNT reduction material and the Ti nano powder slurry (mass ratio: 1:1), heat to 100° C. with a magnetic stirrer again and stir for a long time to form a Ti-blended CNT composite slurry. 4. Print ...

Embodiment 2

[0030] To prepare the field emission cathode of carbon nanotube thin film with double-layer blending structure, firstly, nano-powder titanium (Ti) was dispersed in terpineol with ultra-wavelength time, then ethyl cellulose was added, and heated to 100°C with a magnetic stirrer. Stir for a long time until the ethyl cellulose is completely dissolved to form a Ti dispersion slurry; then mix the Ti slurry with the ordinary CNT slurry to form a Ti-blended CNT composite slurry;

[0031] Secondly, the Ti-blended CNT composite paste was printed on a conductive substrate by screen technology to prepare a single-layer blended structure CNT film;

[0032] Finally, a two-step sintering process was adopted: first, sintering at 500°C for 3 hours in hydrogen or ammonia protective gas to promote the decomposition and evaporation of the organic binder and solidify the CNT composite film, and then sintering at 300°C in the atmosphere for 1.5 hours to form a double Layer blend structure carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com