Method and apparatus capable of realizing safe hot plug of secondary current loop of transforming plant

A secondary current, hot-swap technology, applied in circuits, coupling devices, measuring devices, etc., to ensure the safety of equipment, personal safety, and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

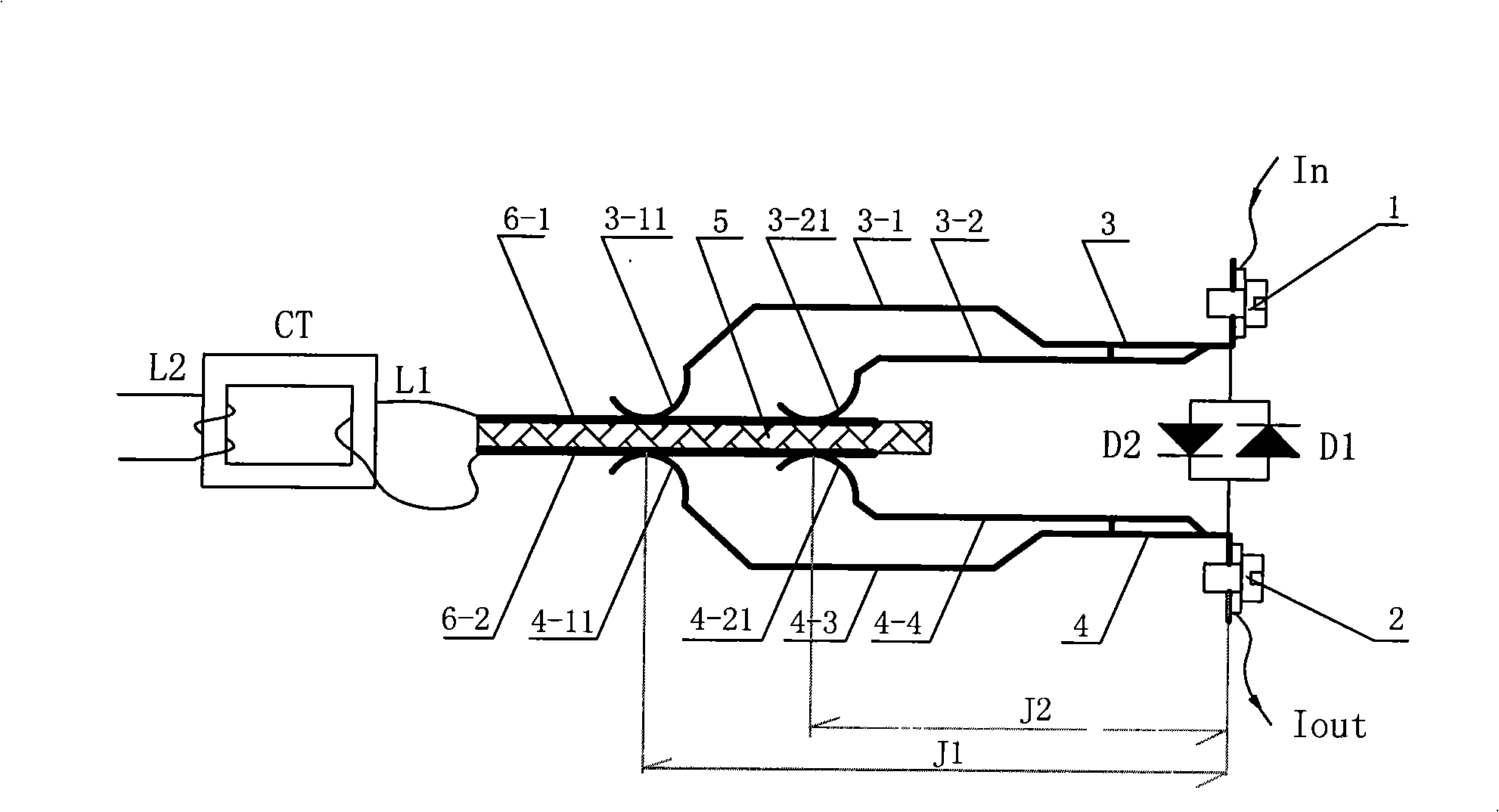

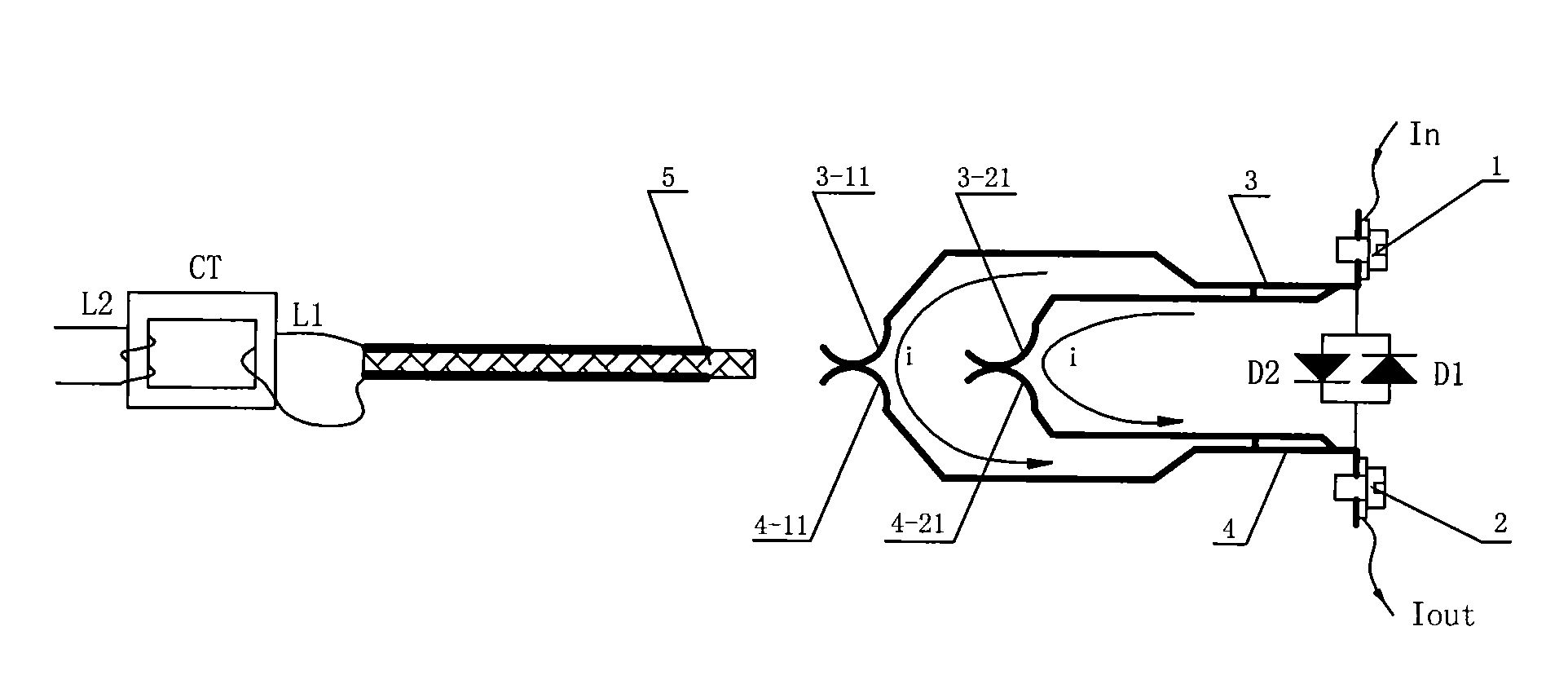

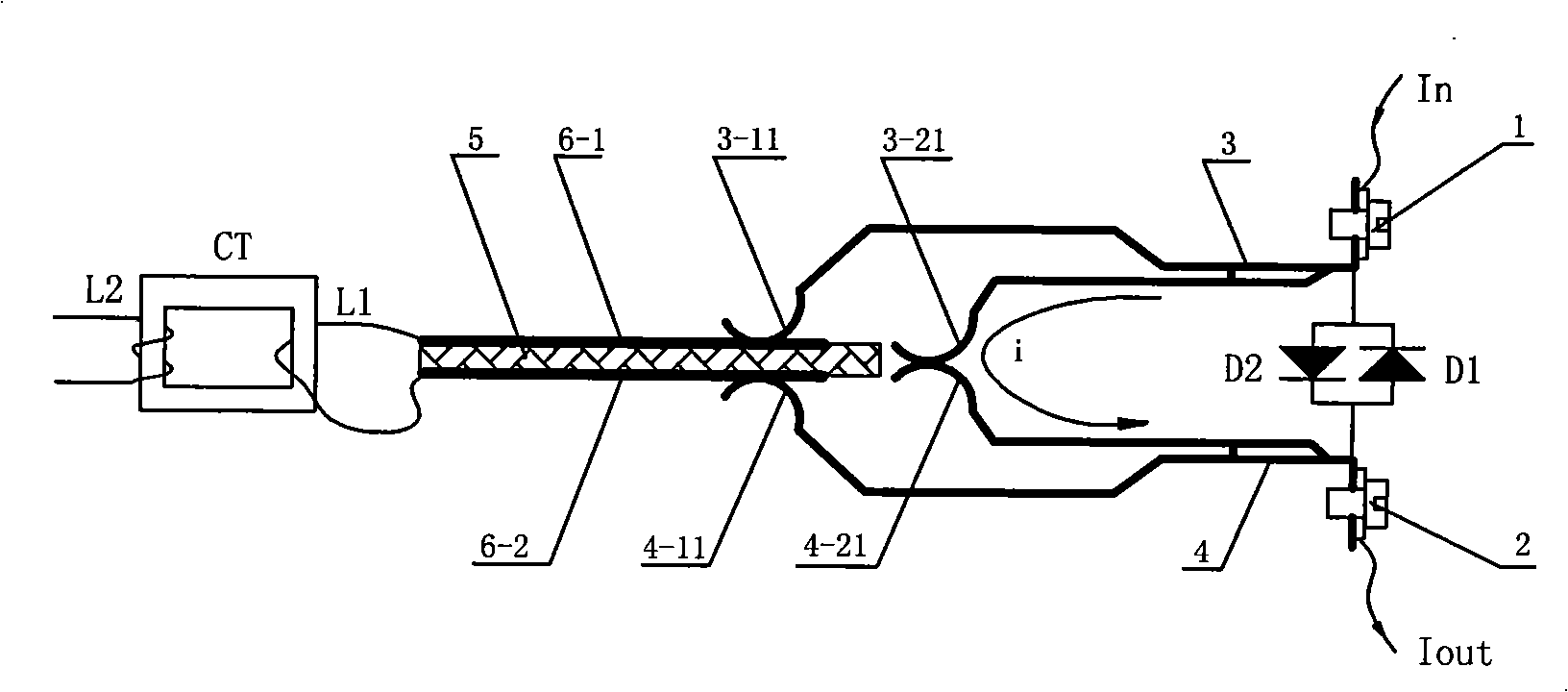

[0035] figure 1 Among them, this technical solution includes the access terminal of the current secondary loop current transformer of the meter meter and the current transformer CT to be connected, which are connected at the first connection end 1 and the second connection end 2 of the current transformer access terminal. Between them, there is a plug-in reed group with double elastic contacts; between the first and second connection ends of the current transformer access terminals, a bidirectional diode group is set; at the same time, a double-sided conductive layer and the two conductive layers are insulated from each other; the conductive layers 6-1 and 6-2 on both sides of the plug-in board are respectively electrically connected to the two ends of the primary coil L1 of the current transformer CT to be connected.

[0036]Specifically, its plug-in reed set with do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com