Harmonic suppression apparatus of ore furnace

A harmonic suppression and submerged arc furnace technology, applied in harmonic reduction devices, AC networks to reduce harmonics/ripples, lighting and heating equipment, etc., can solve transformer copper loss, large reactive power loss, and power consumption Large and other problems, to achieve the effect of improving power factor, improving product quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

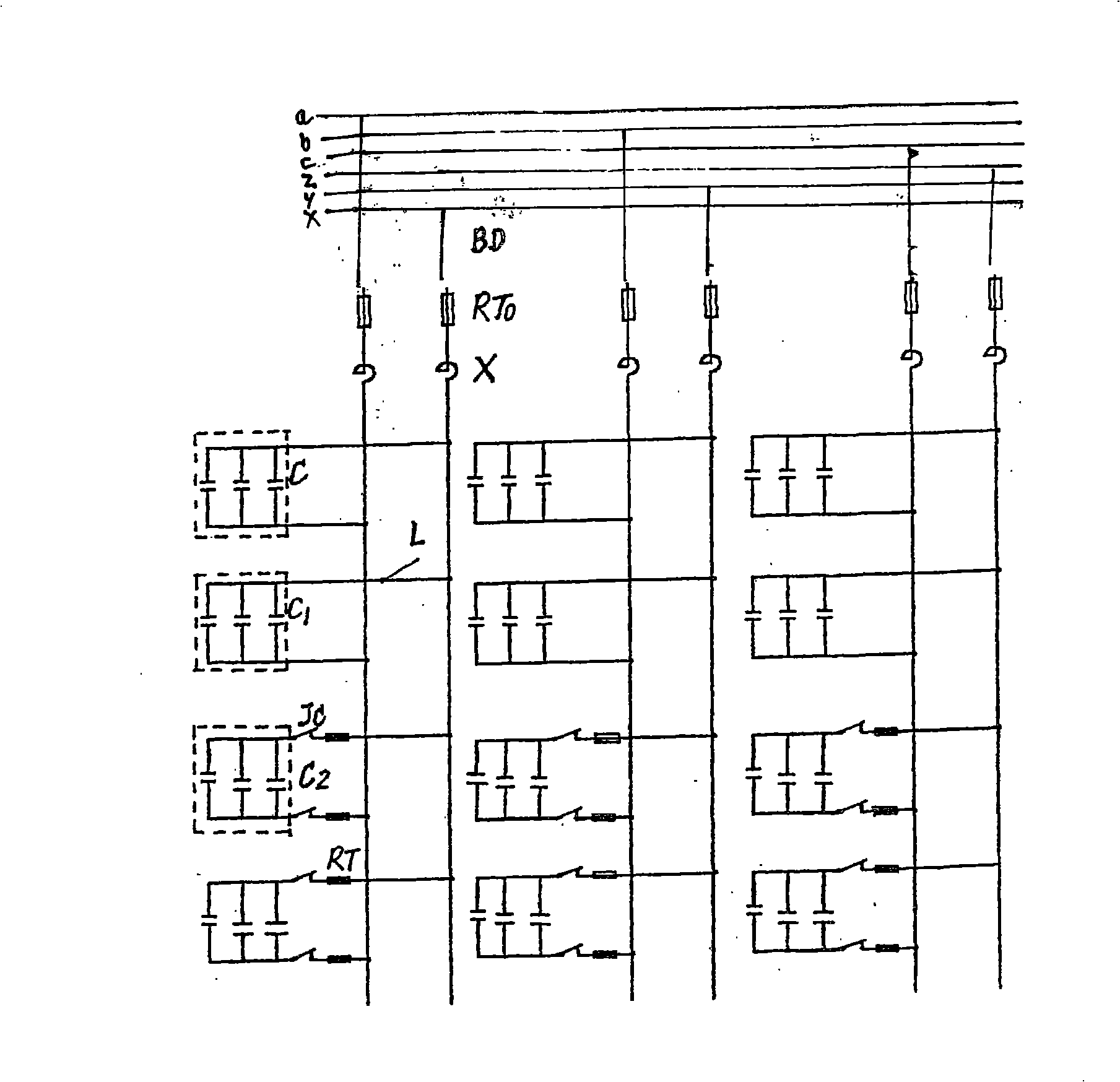

[0022] According to the concrete structure of the submerged arc furnace, the present invention arranges the compensation capacitor in parallel near the copper tile, makes the reactive power compensation as close as possible to the electric arc, and compensates the transformer's secondary reactance, leakage reactance and short network impedance. Automatic control technology is used to detect the reactive power of each phase, and according to the size of the reactive power and the control model that the three-phase power is equal, a corresponding size of reactive capacitor is set to convert the reactive power into active power. This system can not only improve the power factor, but also balance the three-phase power, make the power center, thermal center, and furnace cavity center of the submerged arc furnace coincide, and increase the smelting power on the electrode under the condition that the primary side power of the transformer remains unchanged. , to achieve the purpose of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com