Electric motor

A technology of motors and rotors, applied in the field of motors, can solve the problems of complicated motor control, reversal of size relationship, inability to control phase difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

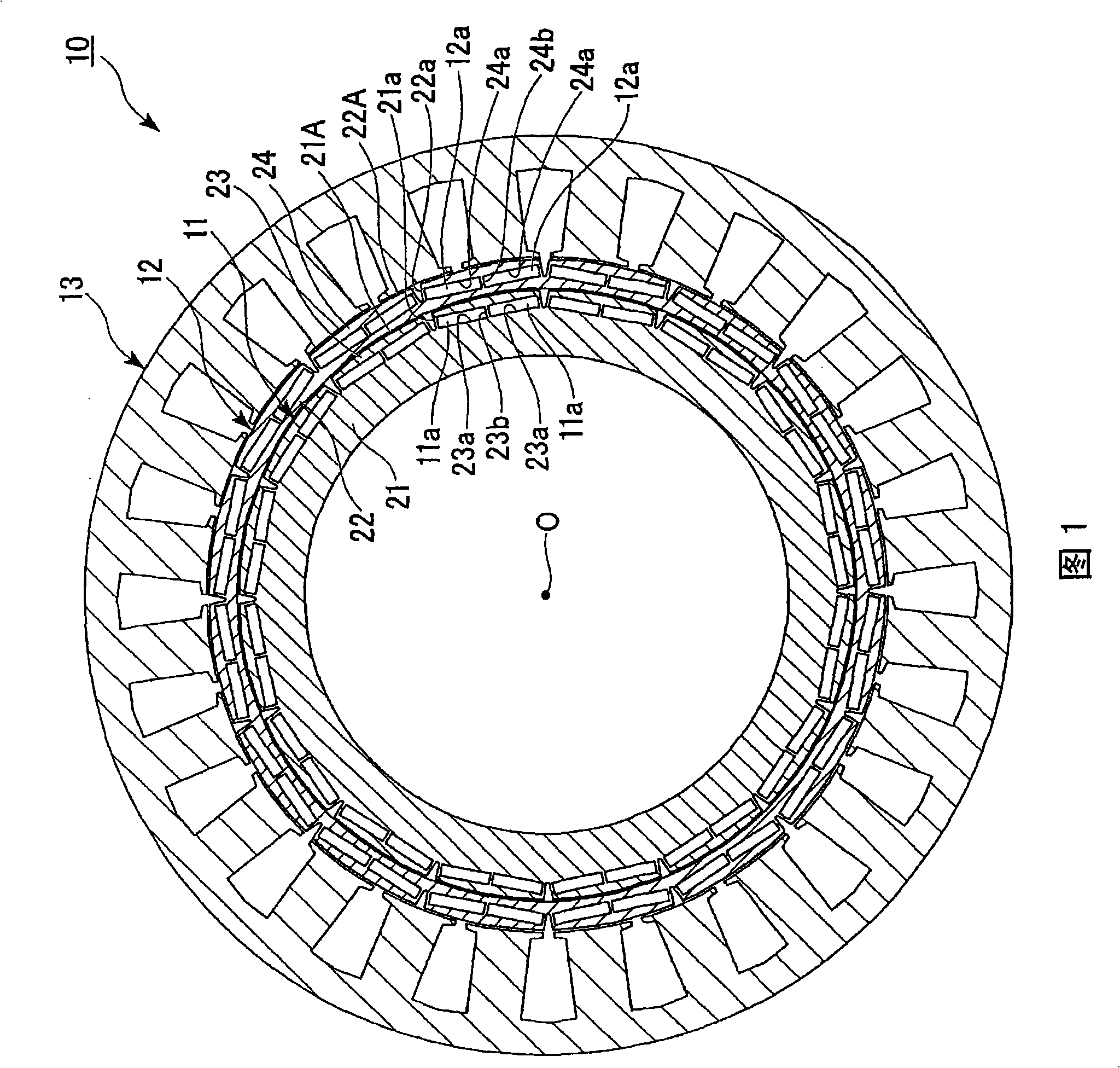

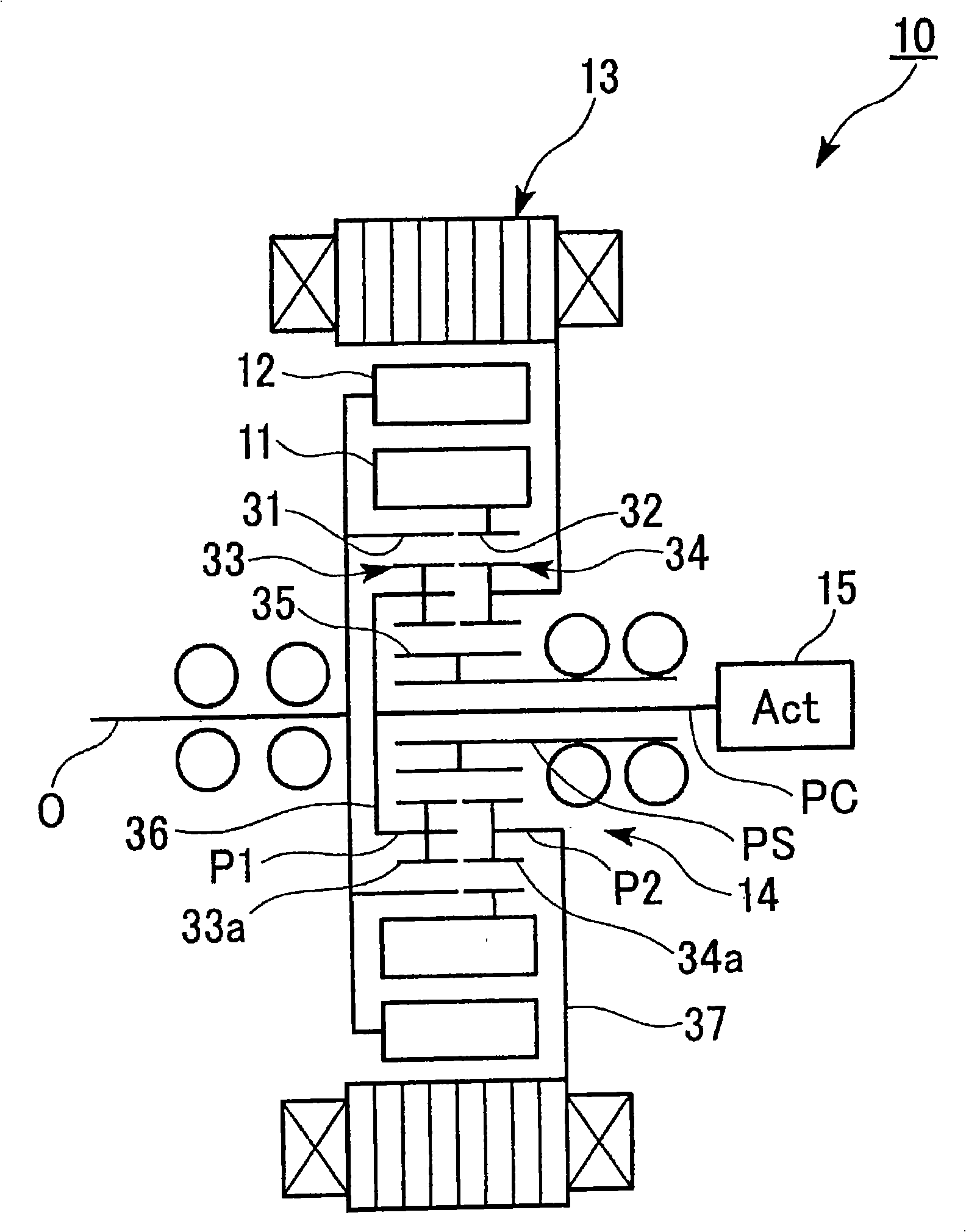

[0118] Next, an embodiment of a motor according to the present invention will be described with reference to the drawings.

[0119] The motor 10 of the present embodiment is, for example, as shown in FIG. 1 , a brushless DC motor including substantially annular inner-circumferential rotors 11 and outer-circumferential rotors 11 provided with permanent magnets 11a and 12a arranged in the circumferential direction. rotor 12; a stator 13 having a plurality of phases of stator windings 13a that generate a rotating magnetic field that rotates the inner rotor 11 and the outer rotor 12; a planetary gear mechanism 14 that connects the inner rotor 11 and the outer rotor 12; The actuator 15 for setting the relative phase between the inner rotor 11 and the outer rotor 12 through the planetary gear mechanism 14 is mounted on a vehicle such as a hybrid vehicle or an electric vehicle as a drive source. An output shaft P of the electric motor 10 is connected to an input shaft of a transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com