Method for improving strength and strain of polyurethane fibers

A polyurethane fiber and polyurethane technology, applied in the direction of single-component polyurethane artificial filament, fiber chemical characteristics, wet spinning method, etc., can solve the problems of increased breaking strength, insufficient mechanical properties of polyurethane fiber, and increased elongation at break. Achieve the effects of strength and strain enhancement, remarkable mechanical control performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A method for improving polyurethane fiber strength and strain, comprising spinning solution preparation, coagulation bath preparation, spinning and post-treatment in the polyurethane fiber preparation process, described method is carried out according to the following steps:

[0040] (1) Preparation of polyurethane spinning solution

[0041] S1: Mix the following three types of solvents into a ternary mixed solvent according to the mass ratio. At room temperature, stir at a stirring speed of 200r / min for 10 minutes to obtain a mixed solvent system. The proportions are as follows:

[0042] Mass fraction of poor solvent for polyurethane: 5% to 45%;

[0043] The mass fraction of N,N-dimethylformamide: 30% to 90%;

[0044] The mass fraction of the solvent whose polarity is lower than that of N,N-dimethylformamide: 5%-30%.

[0045] S2: Polyurethane prepolymer according to the mass ratio: mixed solvent = 30%: 70% ~ 40%: 60% Weigh the polyurethane prepolymer, add the ternary ...

Embodiment 2-8

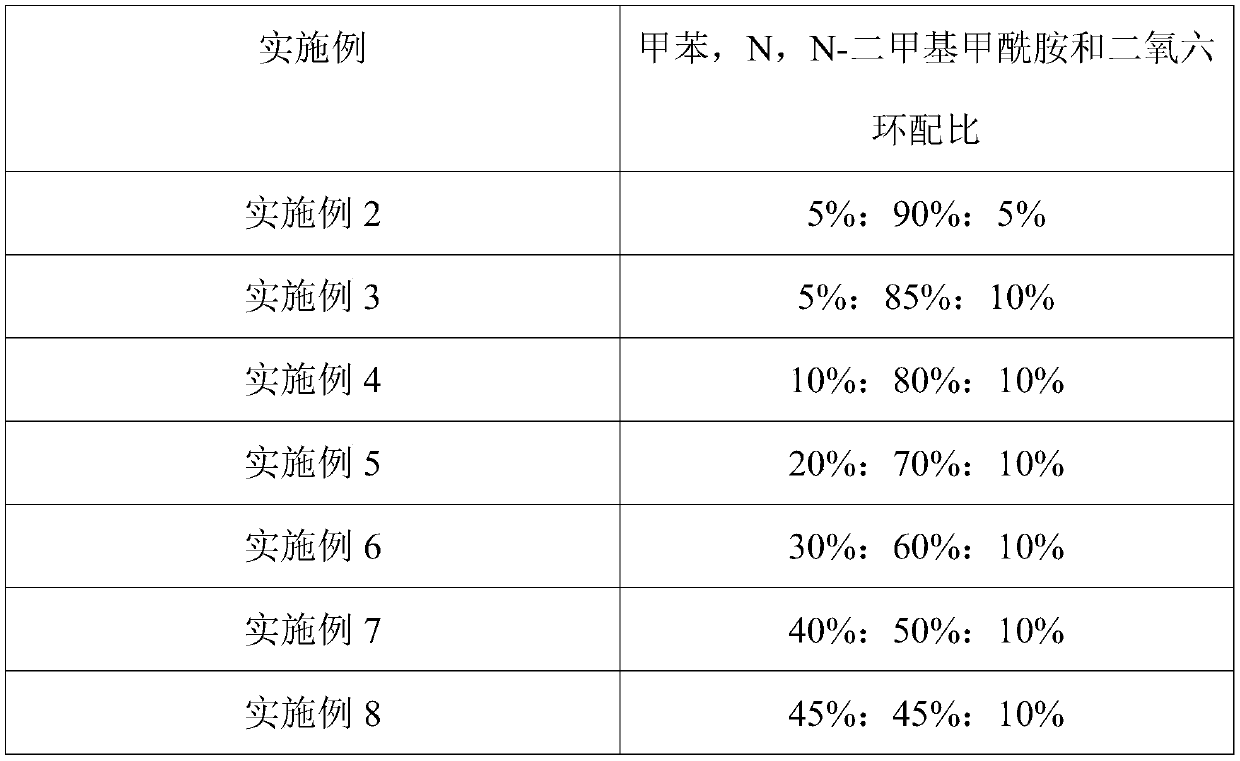

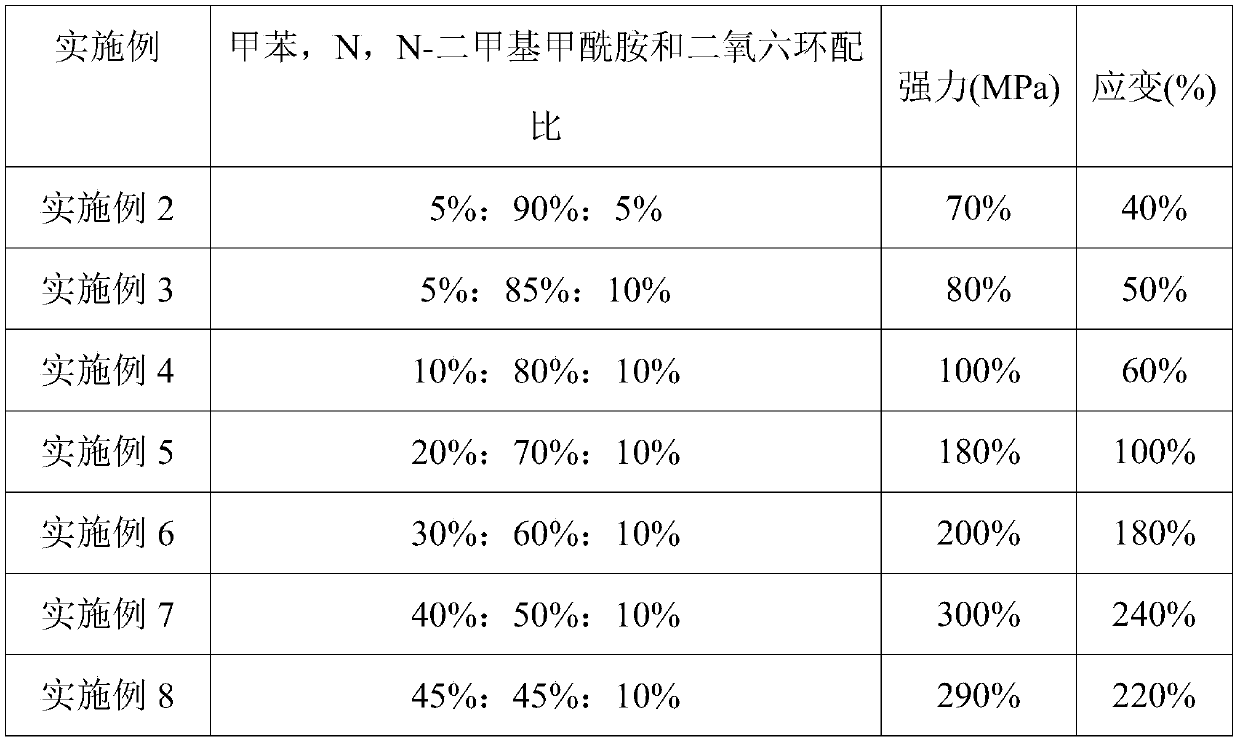

[0061] The mass fraction is as shown in Table 1 Toluene and N, N-dimethylformamide compounded as toluene, N, N-dimethylformamide and dioxane compounded as a ternary mixed solvent, Then, the polyester polyurethane prepolymer with a mass fraction ratio of 30%:70% was mechanically stirred with a ternary mixed solvent for 2.5 hours, and then vacuum defoamed to prepare a polyurethane spinning solution. Wherein, the stirring temperature is 25° C., and the stirring rate is 700 rpm.

[0062] The mass fraction ratio is 95%: 5% deionized water and ethylene glycol are compounded, and after stirring evenly, a coagulation bath is prepared, wherein the conductivity of the deionized water is 16MΩ cm, and the coagulation bath temperature is 40°C.

[0063] After the polyurethane spinning liquid is extruded through spinneret holes of different diameters, it is immersed in a coagulation bath for 20s, and then the incompletely formed polyurethane fibers are subjected to a 0.8-fold drafting treatm...

Embodiment 9-12

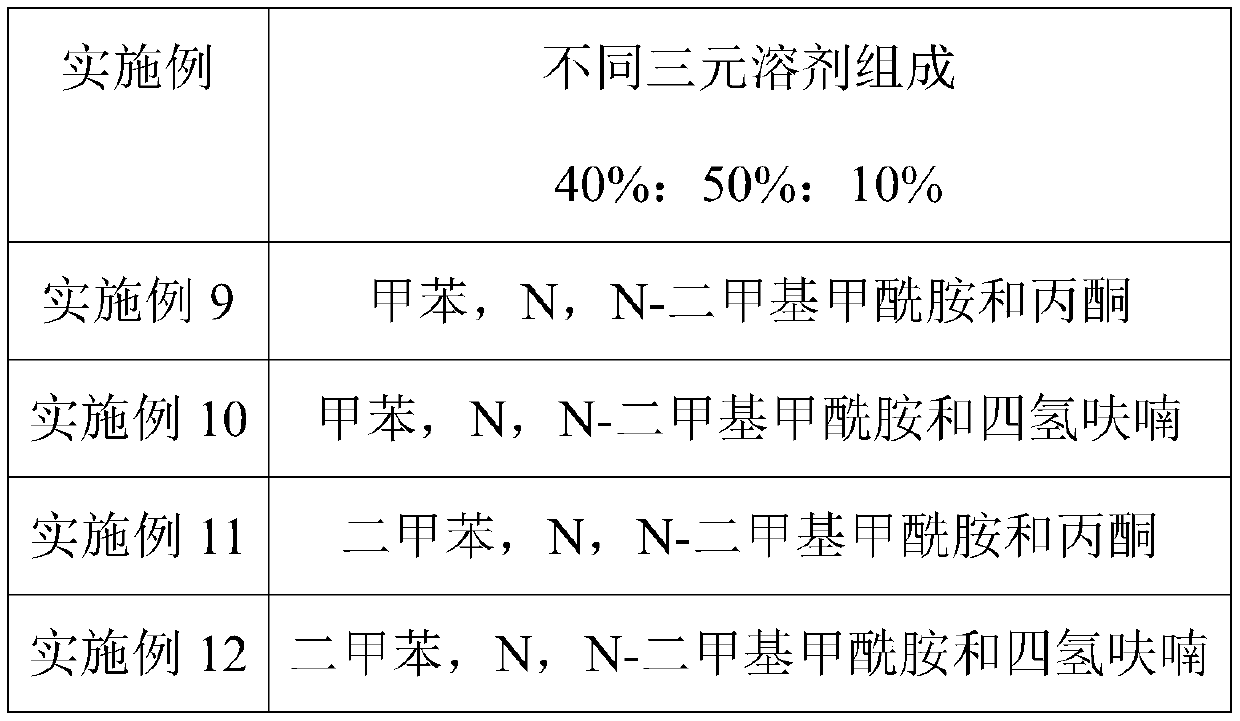

[0070] Embodiment 9-12 is according to the composition of the ternary solvent in Table 3, with the mass fraction ratio being 40%: 50%: 10% compounding ternary mixed solvent, then the mass fraction ratio is 30%: 70% polyester type Polyurethane prepolymer and ternary mixed solvent were mechanically stirred for 2.5 hours, and then vacuum defoamed to prepare polyurethane spinning solution. Wherein, the stirring temperature is 25° C., and the stirring rate is 700 rpm.

[0071] The mass fraction ratio is 95%: 5% deionized water and ethylene glycol are compounded, and after stirring evenly, a coagulation bath is prepared, wherein the conductivity of the deionized water is 16MΩ cm, and the coagulation bath temperature is 40°C.

[0072] After the polyurethane spinning liquid is extruded through spinneret holes of different diameters, it is immersed in a coagulation bath for 20s, and then the incompletely formed polyurethane fibers are subjected to a 0.8-fold drafting treatment, and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com