Electromagnetic vibration table

An electromagnetic vibration and motion table technology, which is applied to fluids, measuring devices, instruments, etc. using vibration, can solve the problems such as the reduction of the output electromagnetic force of the vibration table, the easy distortion of the waveform, and the increase of the non-uniformity of the magnetic induction intensity. Distortion improvement and uniform magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

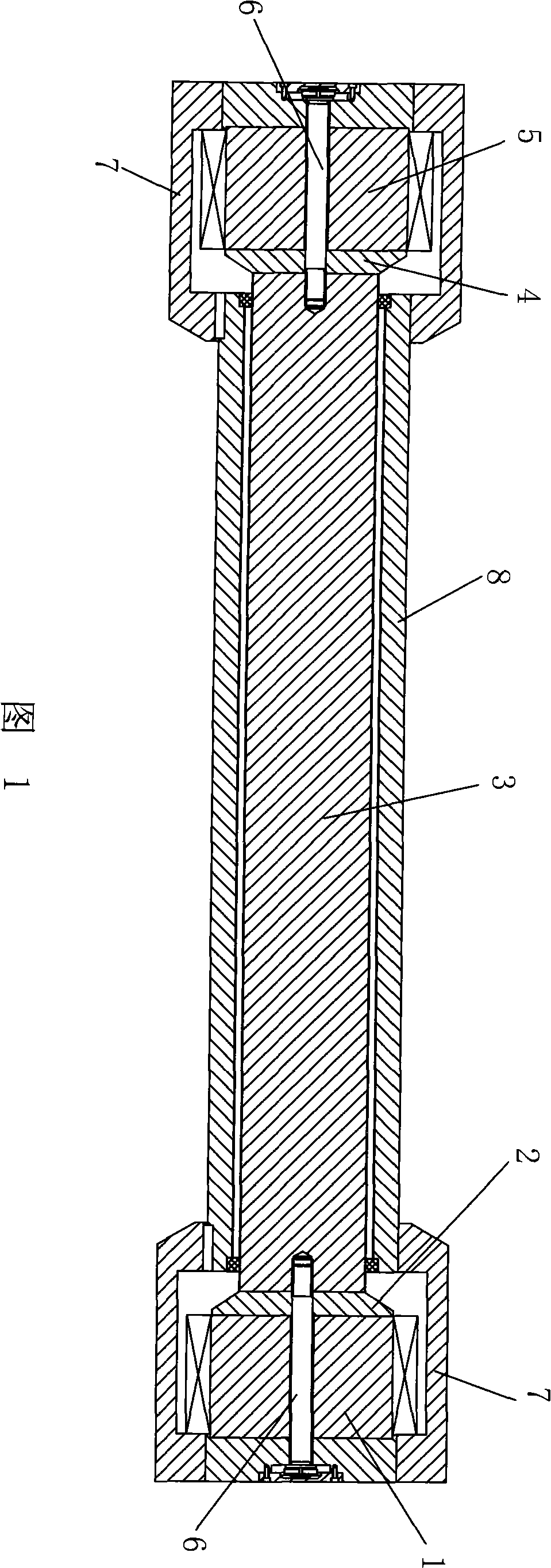

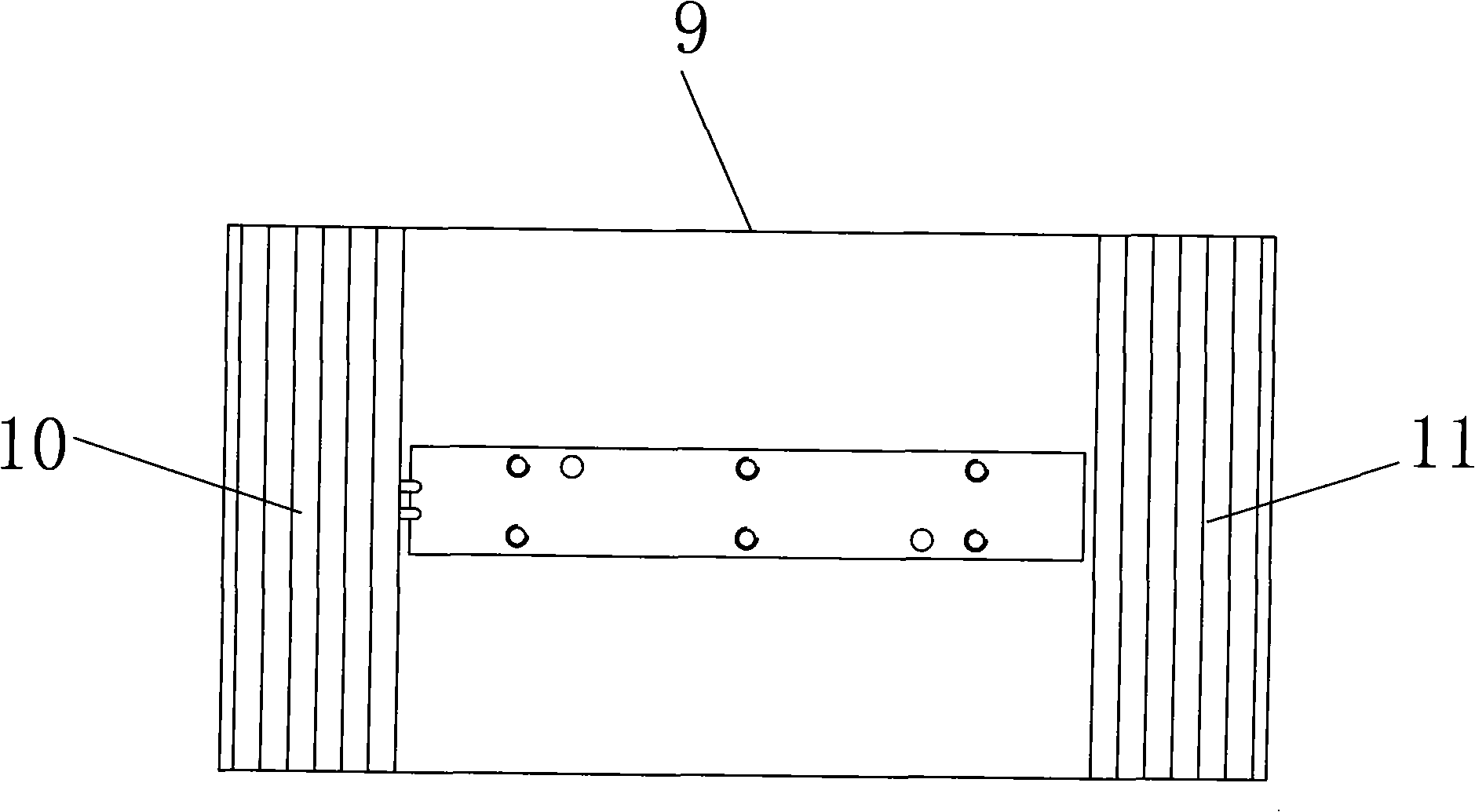

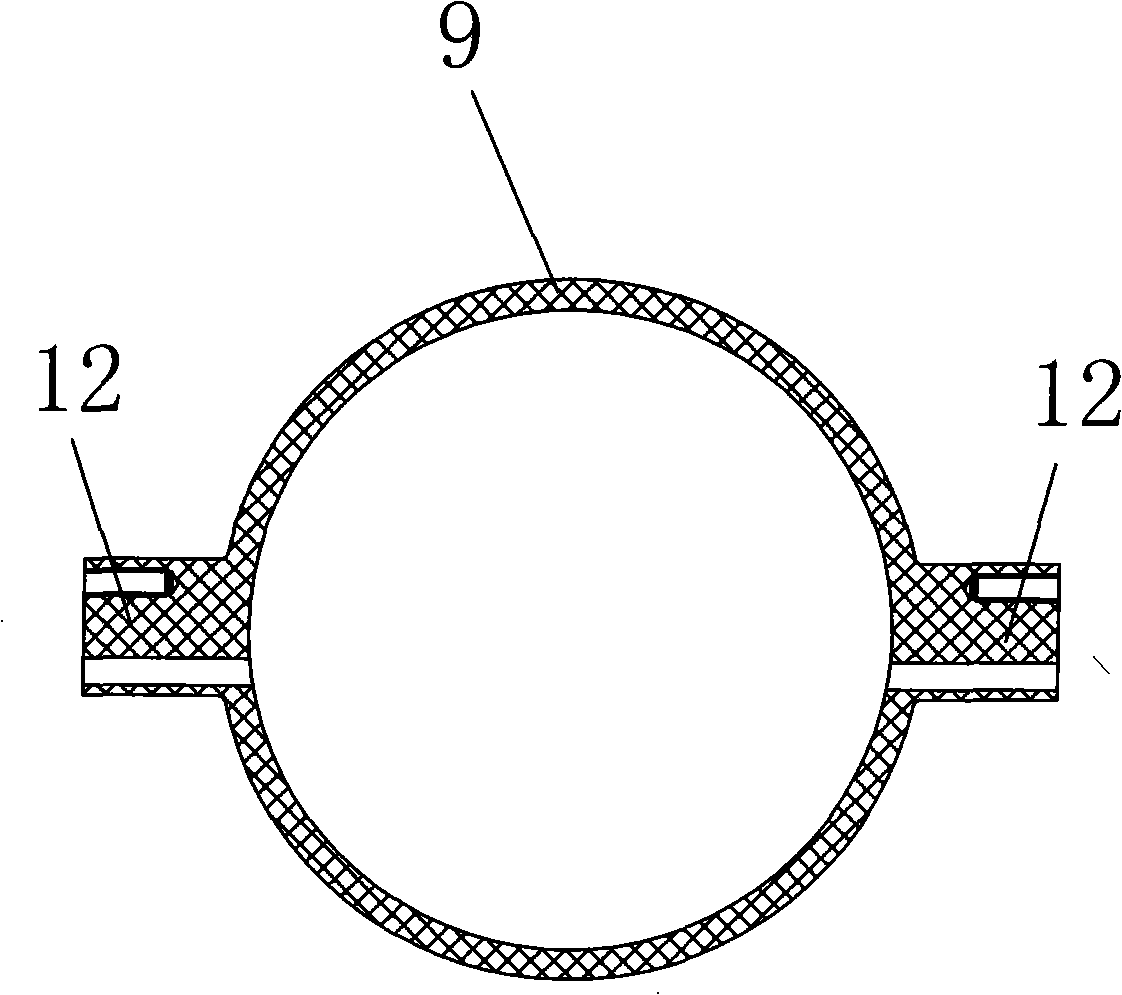

[0032] Refer to Figure 1~ Image 6 , an electromagnetic vibrating table, including a table body, and the table body includes a first magnet 1, a first transition block 2, a central magnetic guide column 3, a second transition block 4, and a second magnet 5 connected in sequence with coaxial lines The first magnet 1 and the second magnet 5 are respectively fixed in the end shell 7 by non-magnetically conductive bolts 6, and the first magnet 1 and the second magnet 5 are opposite to each other with the same magnetic poles, and the central magnetically conductive column 3 The outer coaxial sleeve is provided with an outer magnetic tube 8, the two ends of the outer magnetic tube 8 are respectively fastened to the end shell 7, the central magnetic column 3 and the outer magnetic tube 8 There is an air gap between them. In order to further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com