Absorbent charcoal cleaning machine

A cleaning machine and activated carbon technology, applied in the field of cleaning machines, can solve the problems of dirt in the pores, secondary adsorption pollution, difficult removal of intergranular reduction components, etc., and achieve the effect of preventing material running and continuous cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

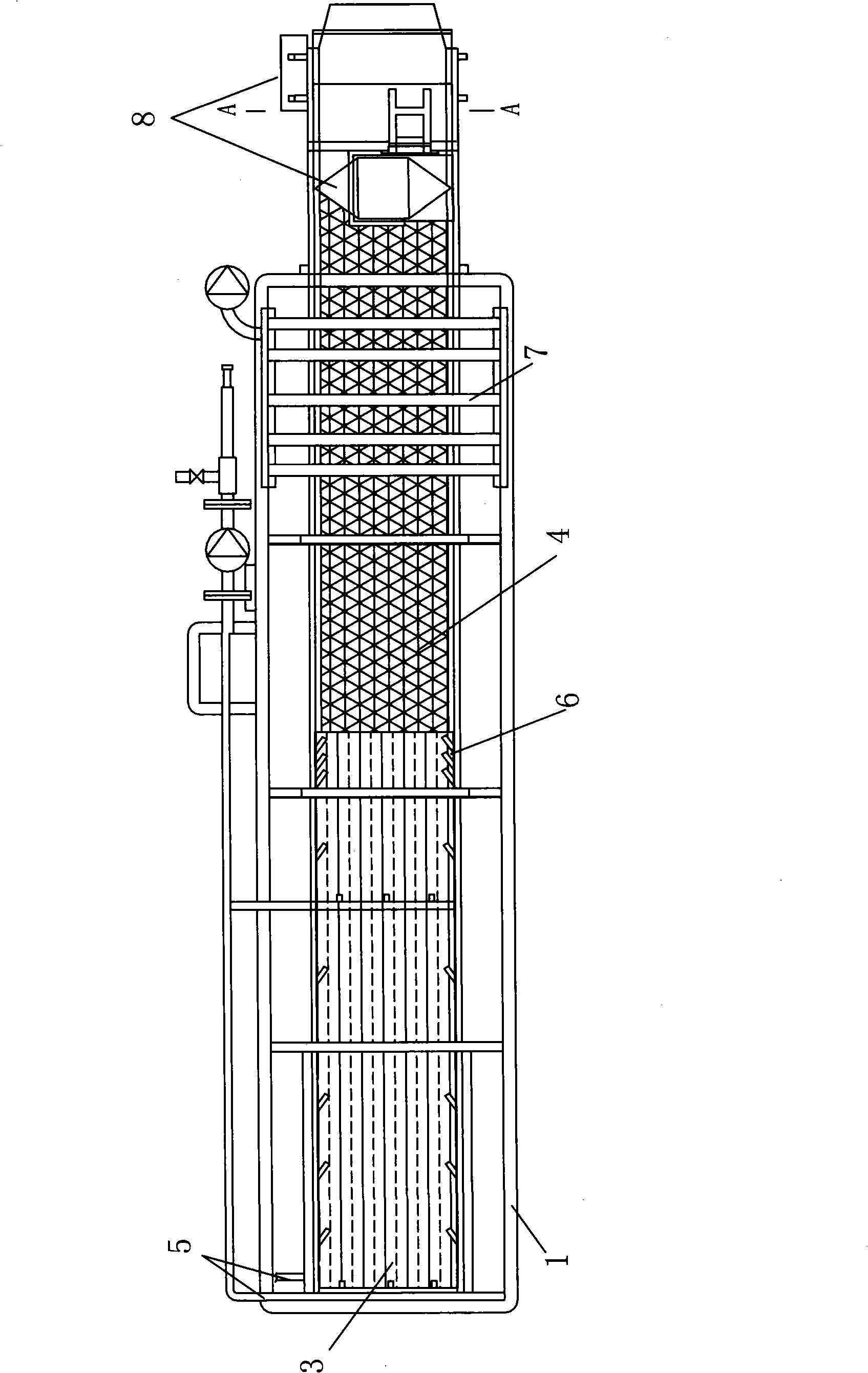

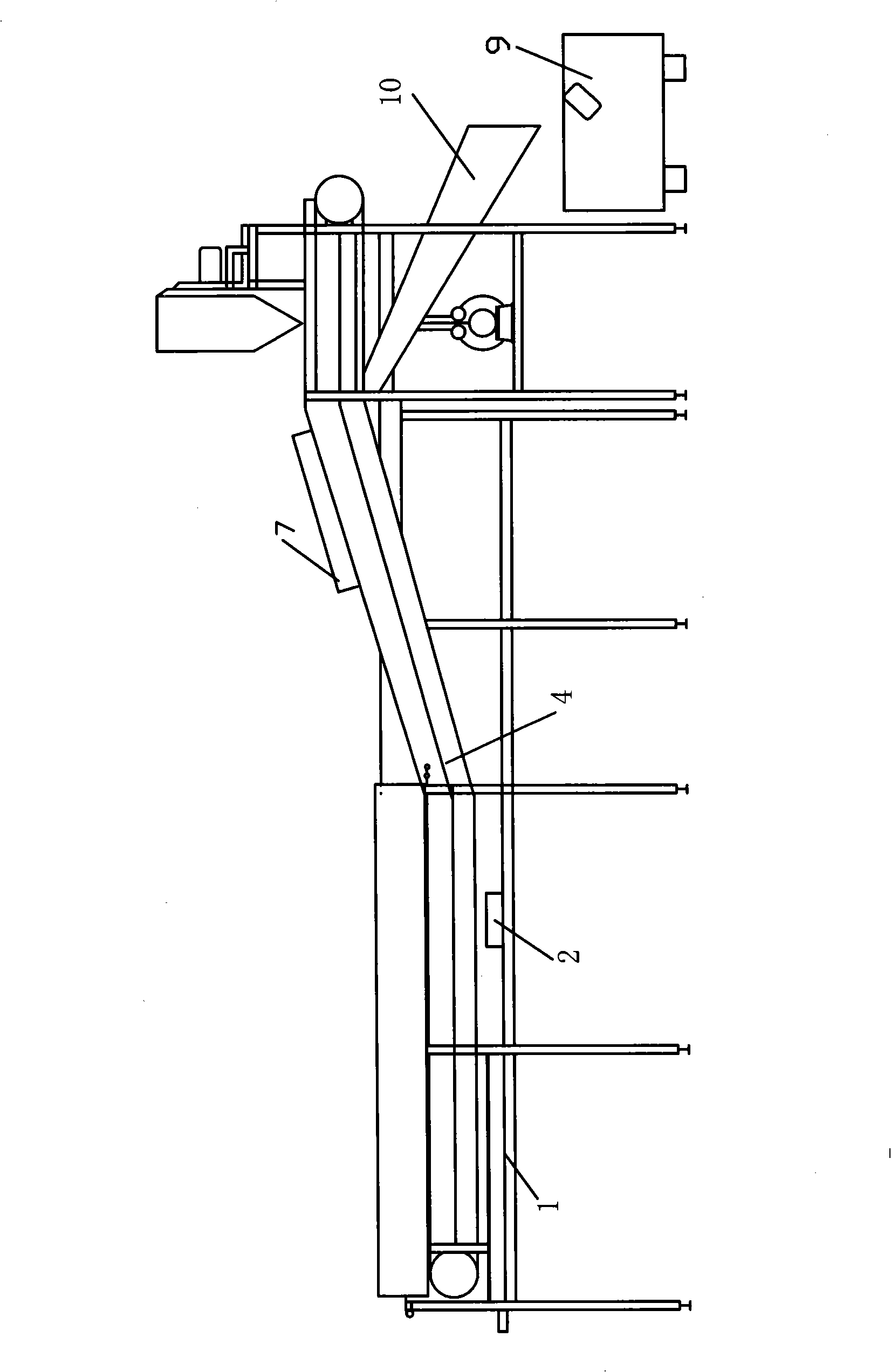

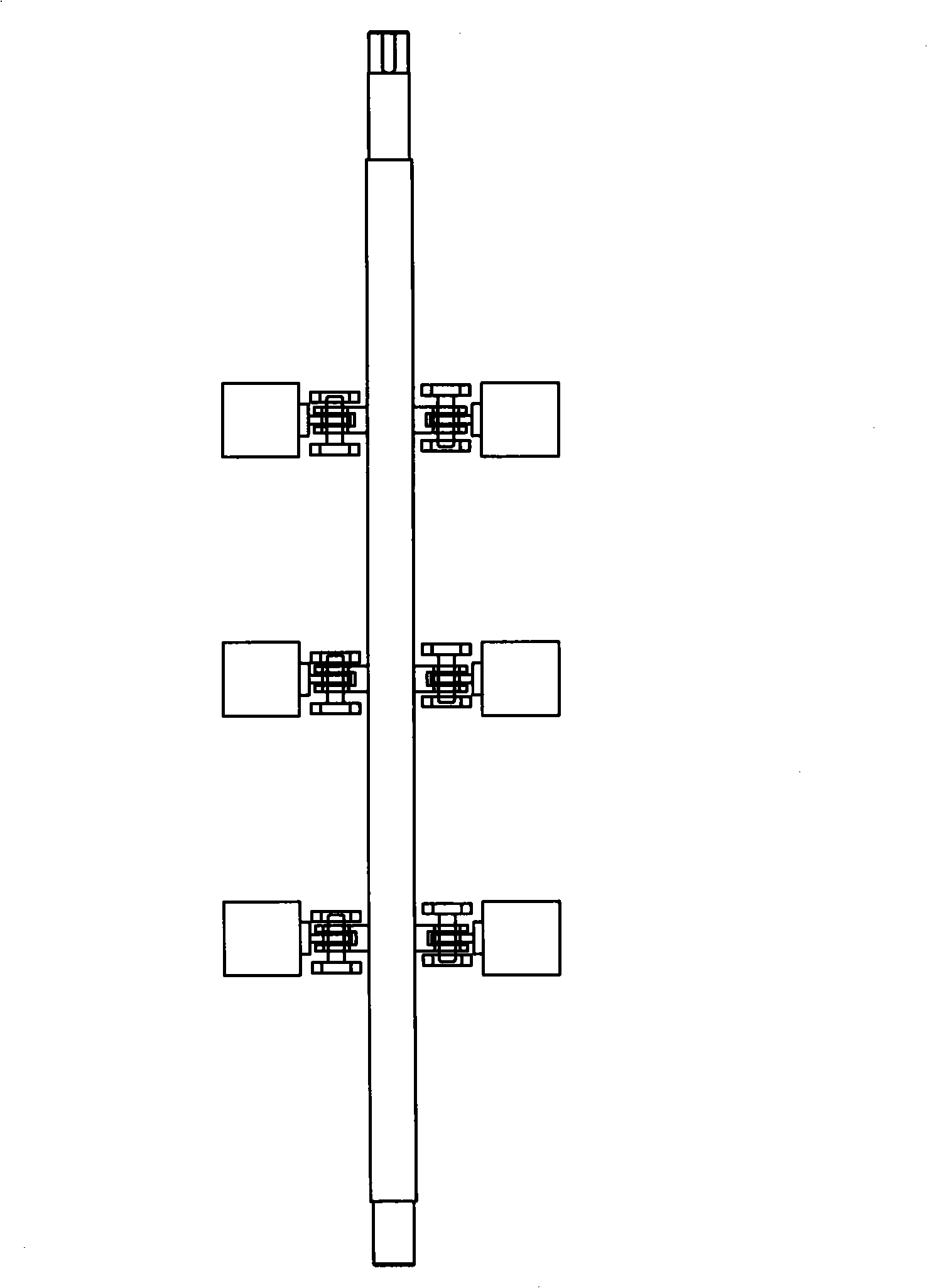

[0025] like figure 1 , 2 As shown, the present invention includes a frame 1, a drain port 2, a net cage 3, a conveying device 4, a bubble type cleaning and a hydraulic flushing device 5, a deviation correcting device 6, a spray rinsing device 7, a wind blowing and slapping blanking device 8, Microseismic draining device 9, hopper 10. Both sides of the frame 1 are provided with drainage outlets 2, and the conveying device 4 is arranged on the frame 1, and above the conveying device 4, a net cage 3, a deviation correcting device 6, a spraying and rinsing device 7, a wind blowing and Slapping blanking device 8, net cage 3 is provided with air bubble cleaning and hydraulic flushing device 5, wind blowing and slapping blanking device 8 is provided with trough 10, and below trough 10 is provided with micro-vibration draining device 9.

[0026] Net cage 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com