Method for supplying membrane onto recessed surface of plastic member and produced wave collector

A technology of wave collectors and composite films, applied in the field of wave collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method of the present invention is described in detail below:

[0017] The present invention adopts following scheme:

[0018] a. The punch of the forming mold of the plastic part is itself also the punch of the drawing die;

[0019] b. The manufacture of the plastic part includes the following steps:

[0020] 1). Press down on the membrane material:

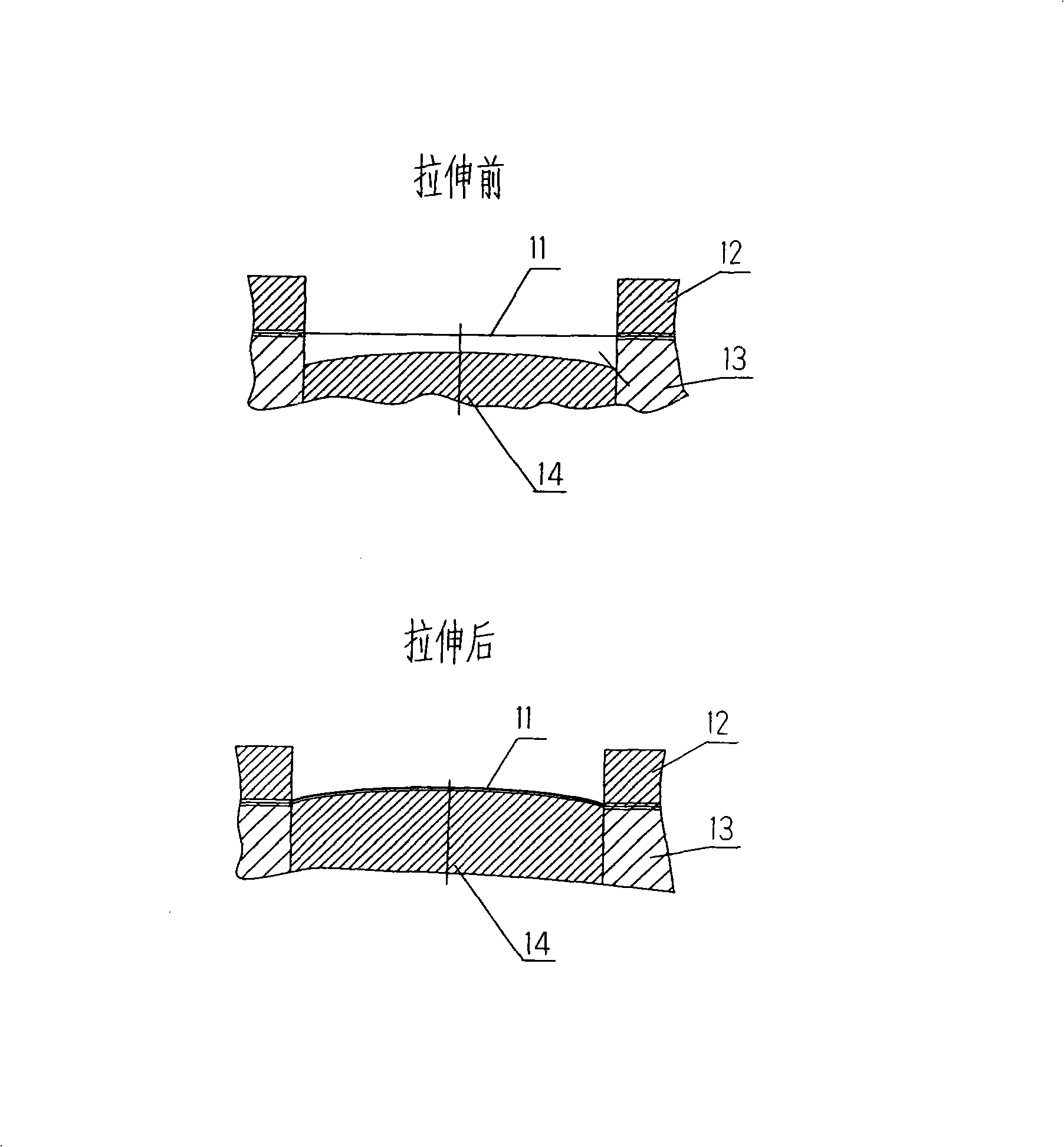

[0021] The film-type materials used are generally rolled when they leave the factory. After slitting, their area should be slightly larger than the projection surface of the inner concave surface of the compounded part, so that the blank-holder width of the material required for stretching is left. like figure 1 Shown: Before stretching, the flat membrane material 11 is pressed down with a blank holder 12, and the pressure should correspond to the required tension of the stretching material. The material of the blankholder should be able to withstand the temperatures likely to be reached when the plastic is molded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com