Stick manufacture machine of plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

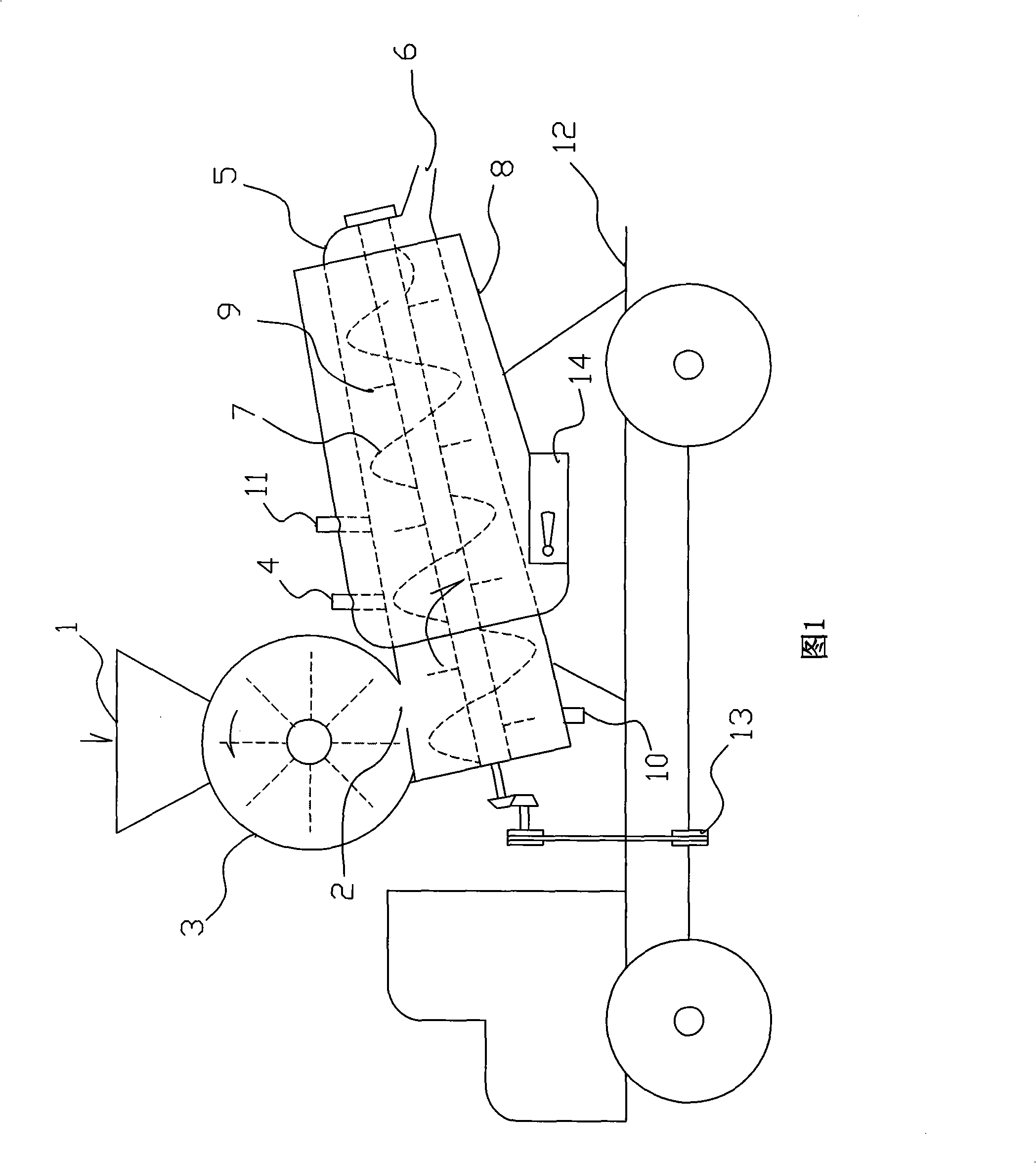

[0014] As shown in the figure, the plant rod making machine of the present invention includes a crushing device 3 with inlet and outlet ports 1, 2 and an extrusion molding device arranged on the motor vehicle body 12; the power source of the motor vehicle is driven by The mechanism 13 is connected to the crushing device 3 and the power shaft of the extrusion molding device; the extrusion molding device is composed of an extrusion chamber and an extrusion device placed therein; the outlet 2 of the crushing device 3 enters the extrusion chamber The material ports are connected; an adhesive filling port 4 and a combustion-supporting agent filling port 11 are opened on the side wall of the extrusion chamber; a heating device is provided on the outer wall of the extrusion chamber. The extrusion chamber is an extrusion barrel 5 with a cylindrical structure, the inner diameter of the extrusion barrel 5 gradually shrinks and becomes smaller from the end of the feed port to the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com