SLD light source automatic filtering system

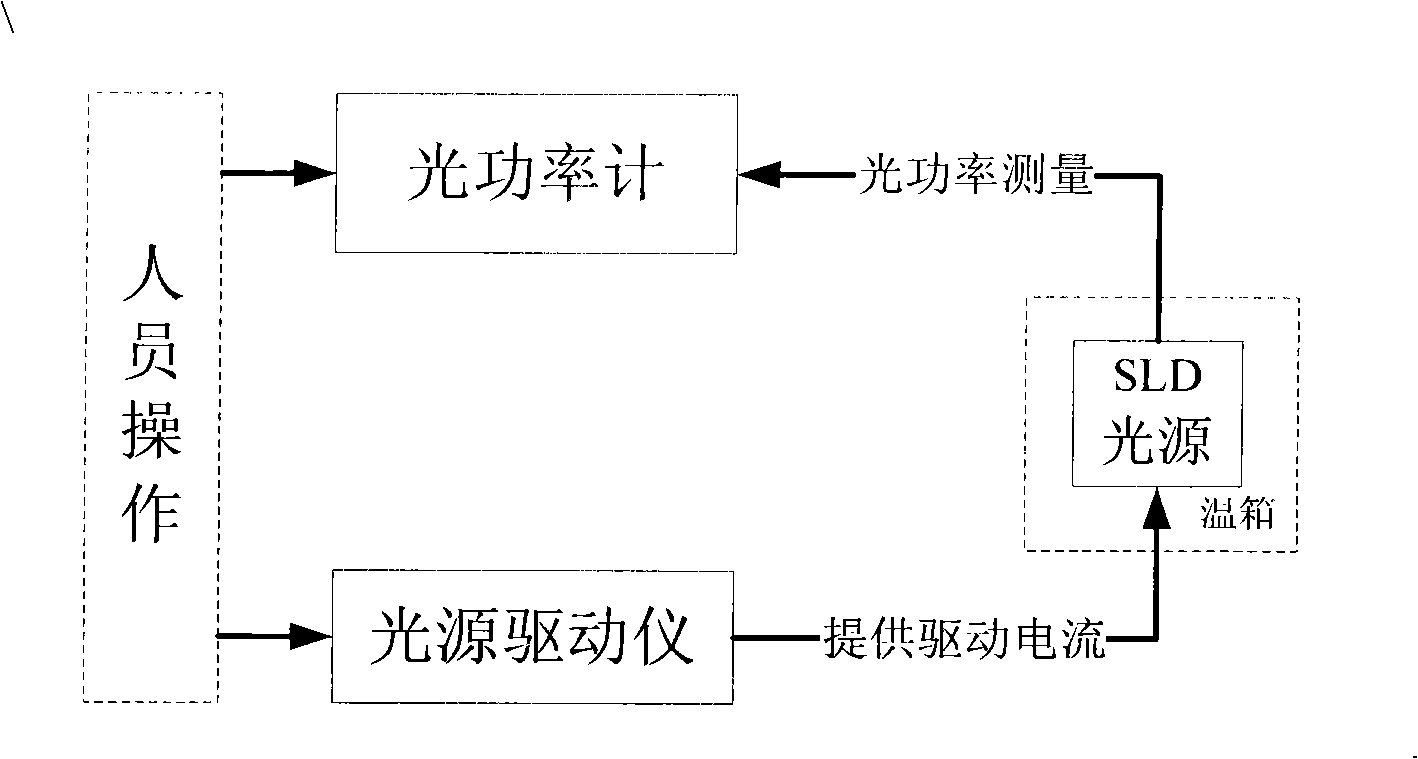

An automatic screening and light source-driven technology, which is applied in photometry, optical radiation measurement, and optical performance testing, can solve the problems of low screening efficiency, affecting the comprehensiveness and accuracy of performance data, and low integration, so as to improve integration The degree of automation and automation, comprehensive and accurate data collection, and the effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

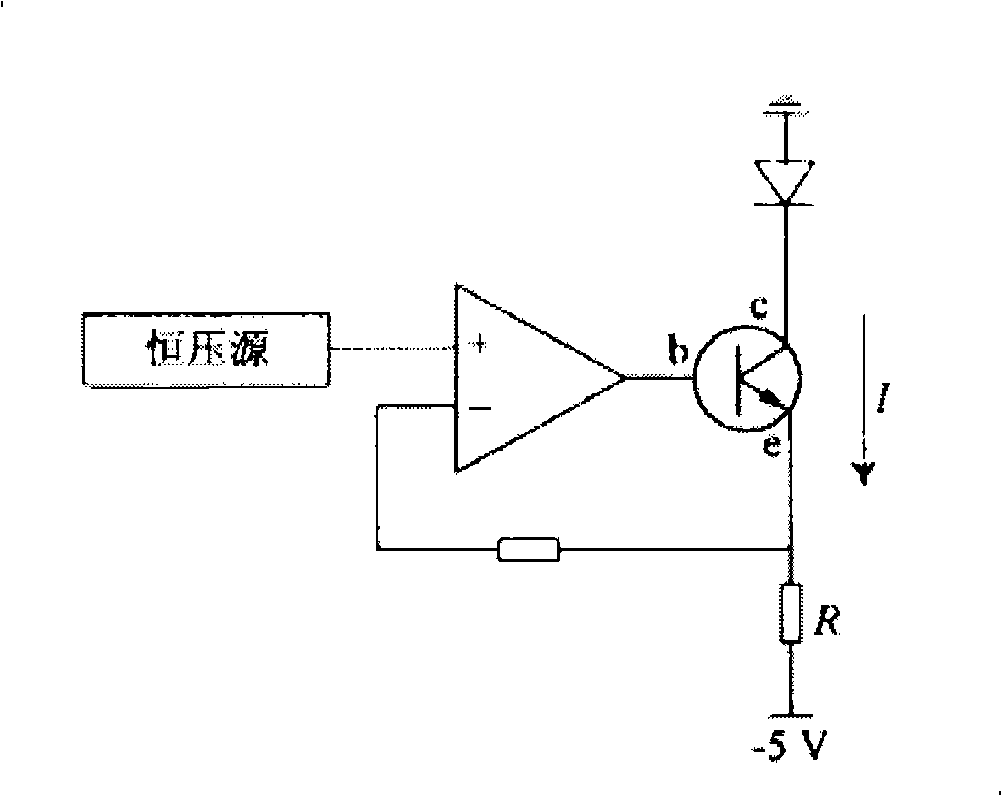

Method used

Image

Examples

Embodiment Construction

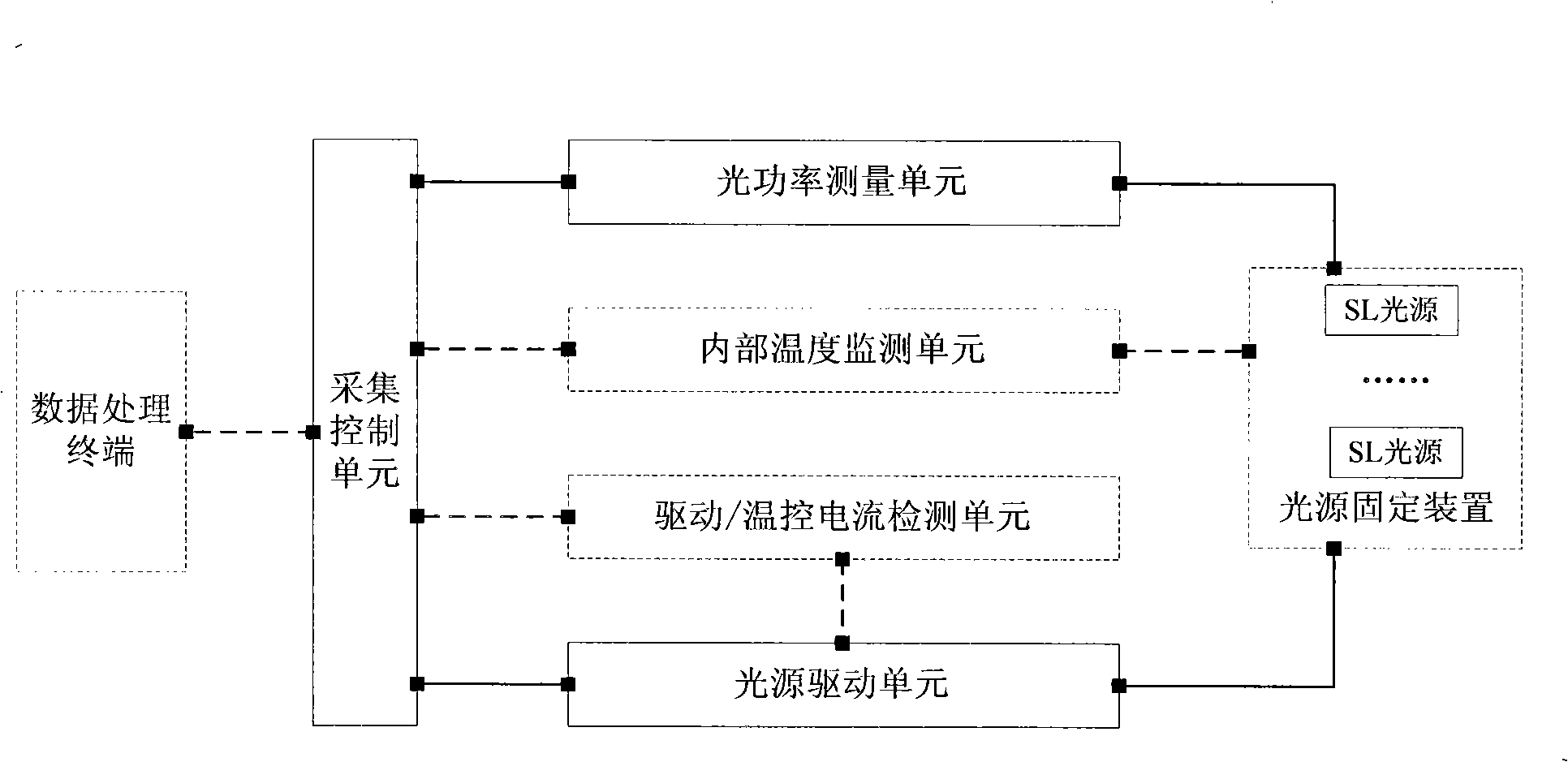

[0035] The embodiment of the present invention provides a system for automatic screening of SLD light sources. The system integrates SLD light source drive, SLD light source performance parameter measurement and data monitoring during the screening process, which effectively improves the integration of screening; at the same time, the measurement data collected by the subsequent acquisition control unit can be processed through the terminal processing equipment. Corresponding processing and analysis, so that the real-time online collection and recording of measurement data and the analysis and processing of screening results are completed through specific processing procedures, which further improves the automation of screening and thus improves system performance.

[0036] In order to better describe the embodiments of the present invention, the specific embodiments of the present invention are now described in conjunction with the accompanying drawings, as figure 2 Shown is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com