Measuring apparatus for reflection index of wave suction material

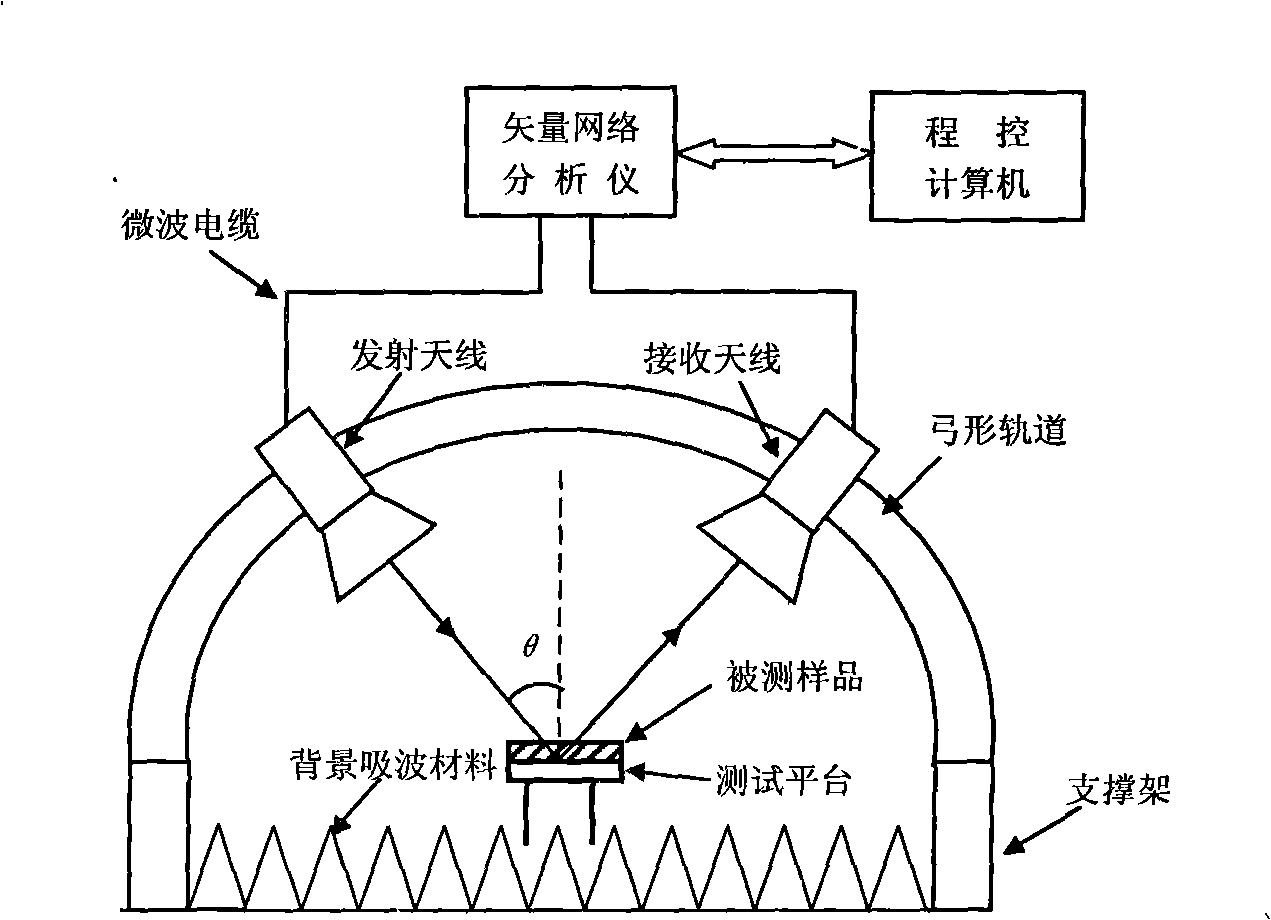

A technology of wave absorbing material and measuring device, which is applied in the field of microwave and millimeter wave testing, can solve the problems that affect the measuring accuracy of reflectivity of wave absorbing material, the machining accuracy of radius consistency is low, and the space occupied by the arcuate track is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

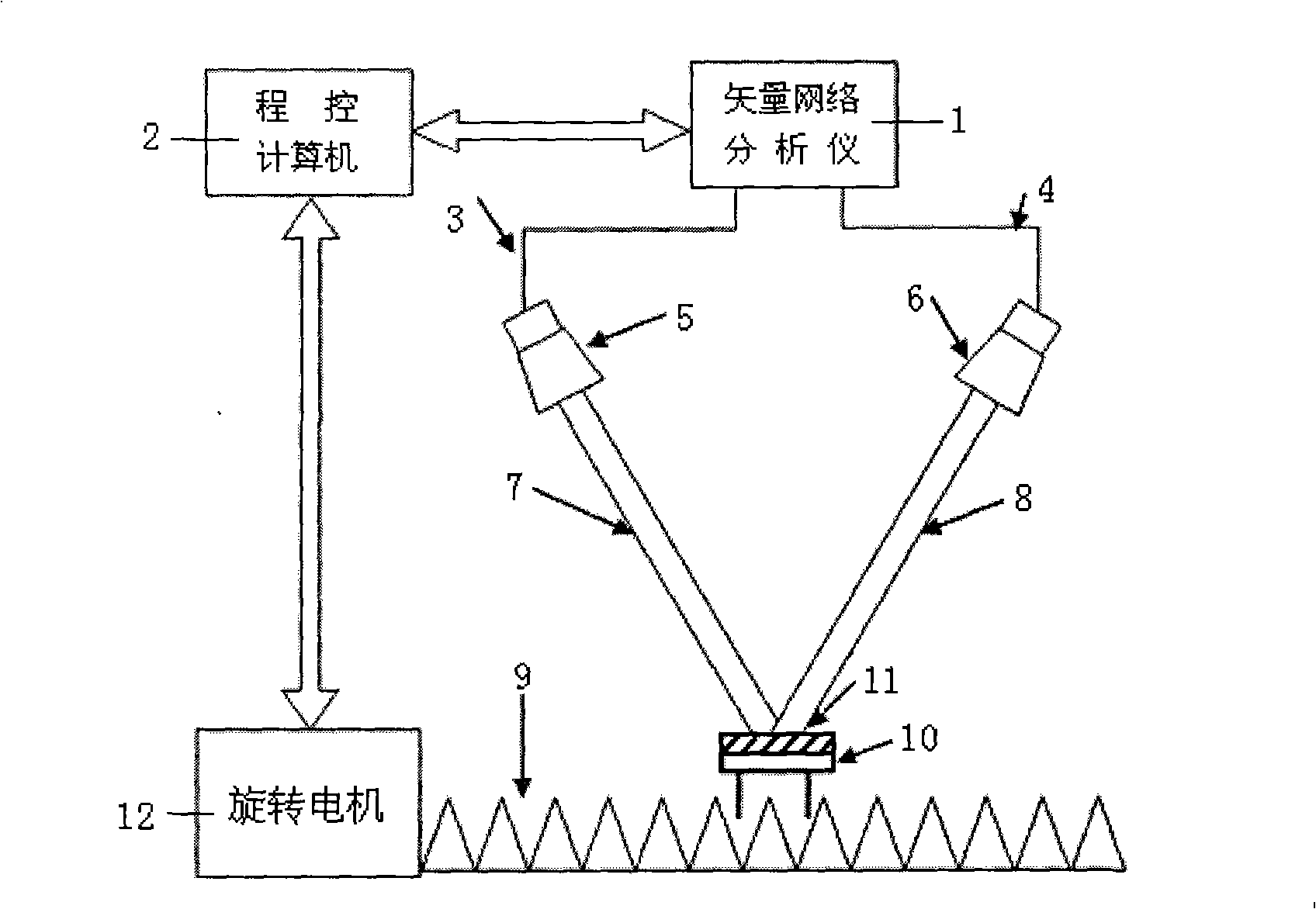

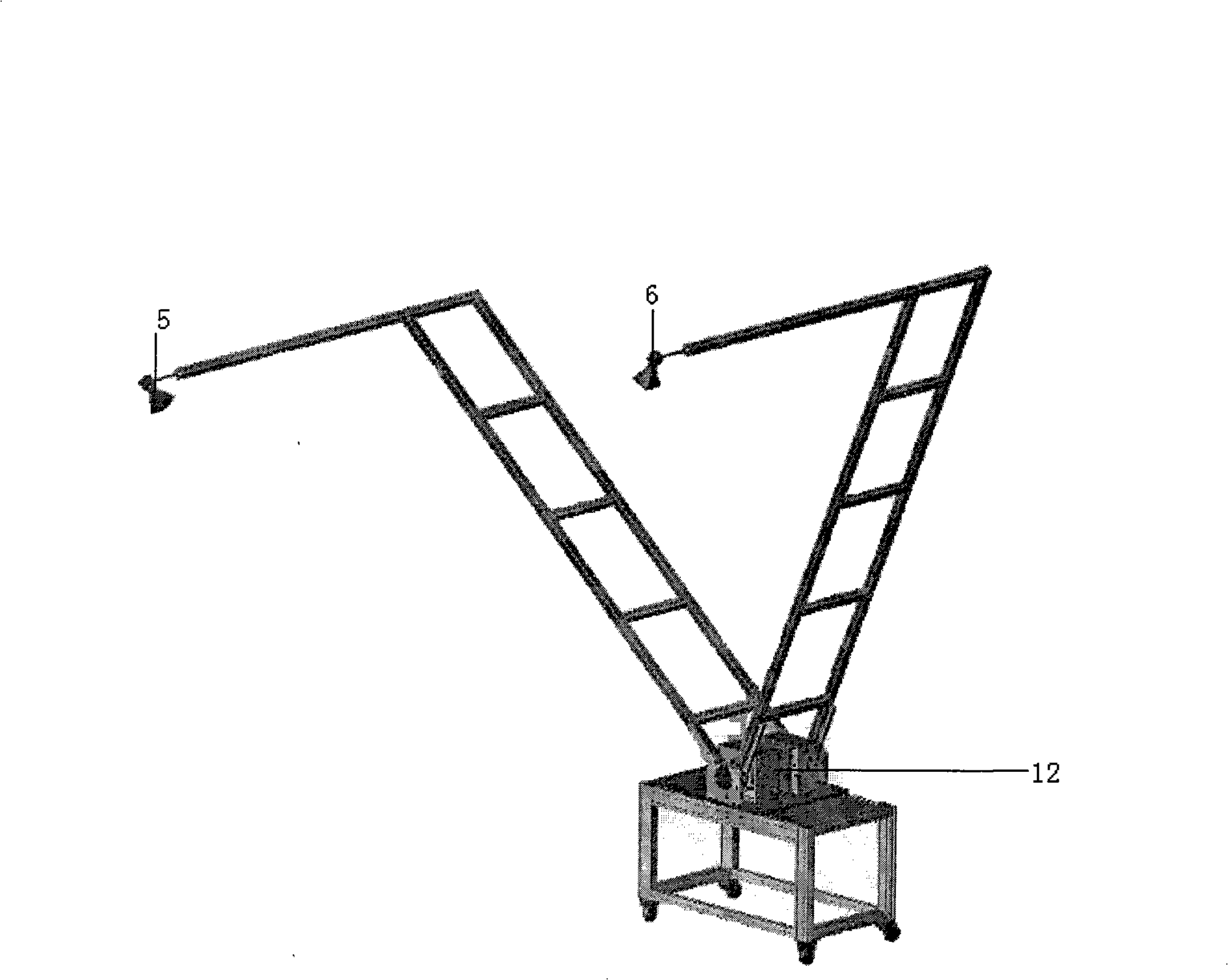

[0028] A device for measuring the reflectivity of absorbing materials, such as figure 2 , image 3 As shown, it includes a vector network analyzer 1, a program-controlled computer 2, a first microwave cable 3, a second microwave cable 4, a transmitting antenna 5, a receiving antenna 6, a first arm 7, a second arm 8, and a background absorbing material 9. Test platform 10, rotating motor 12. The vector network analyzer 1 and the program-controlled computer 2 are connected through a GPIB card, the vector network analyzer 1 and the transmitting antenna 5 are connected through the first microwave cable 3, and the vector network analyzer 1 and the receiving antenna 6 are connected through the first microwave cable. The two microwave cables 4 are connected, and the background absorbing material 9 is located under the test platform 10 .

[0029] Both the first arm 7 and the second arm 8 are in the shape of a "7", have the same size and structure, and are composed of a straight arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com