Method for producing Caragana Microphylla biological feed

A technology of biological feed and production method, applied in animal feed, animal feed, application, etc., can solve the problems of high content of harmful components tannin, affecting the feeding value of caragana, blank caragana, etc., to achieve vigorous growth of shrubs, improve Palatability, palatability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

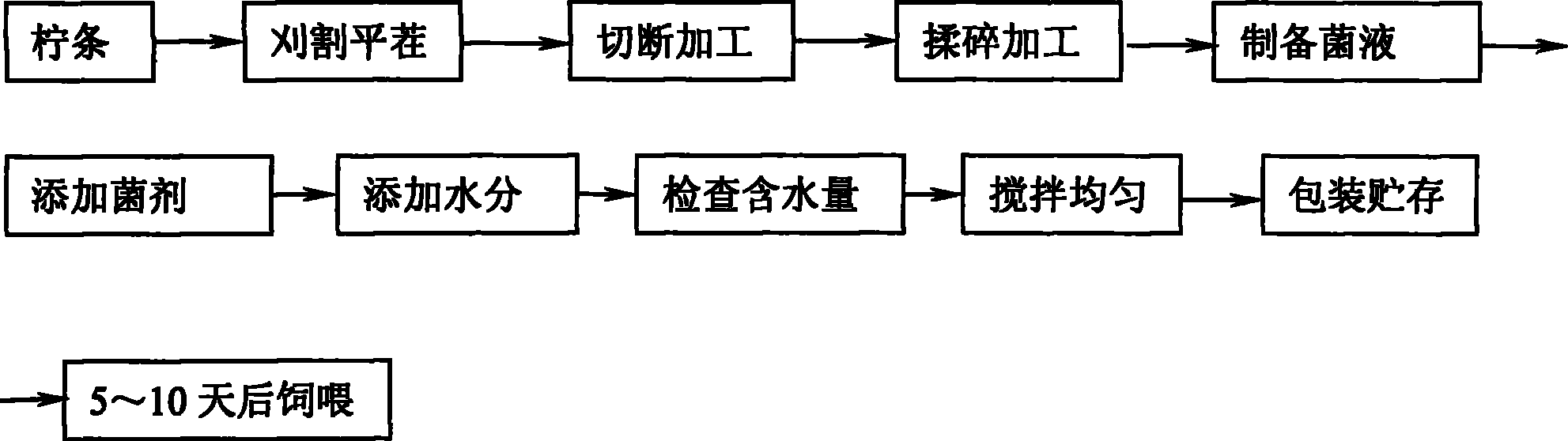

Image

Examples

Embodiment Construction

[0014] 1. Caragana harvest

[0015] Choose the caragana field that has been planted for 5 years and is suitable for mechanized operation without stubble. The stubble should be stubbled according to the regulations of the forestry department, and a stubble height of 8 cm should be left. After harvesting, it should be transported back to the production and processing point immediately.

[0016] 2. Crumble the branches

[0017] After the caragana branch raw materials are recovered, they are crushed and crushed with special machinery. It is required that the raw materials fed to cattle should be crushed into filamentous or powdery materials with a length of no more than 5cm and a thickness of no more than 2mm. The crushed materials should be piled up to an appropriate size. The heap spare.

[0018] 3. Microbial treatment

[0019] 1. Preparation of raw materials:

[0020] The following supplies should be prepared in advance

[0021] a. 1 kg Alltech composite biological agent

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com