Method for rapid cooling of a hot isostatic press and a hot isostatic press

A hot isostatic press, rapid cooling technology, applied in the press, material forming press, heat transfer modification and other directions, can solve the problems of different cooling rates, sudden cooling, complex structure, etc., to achieve uniform temperature distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

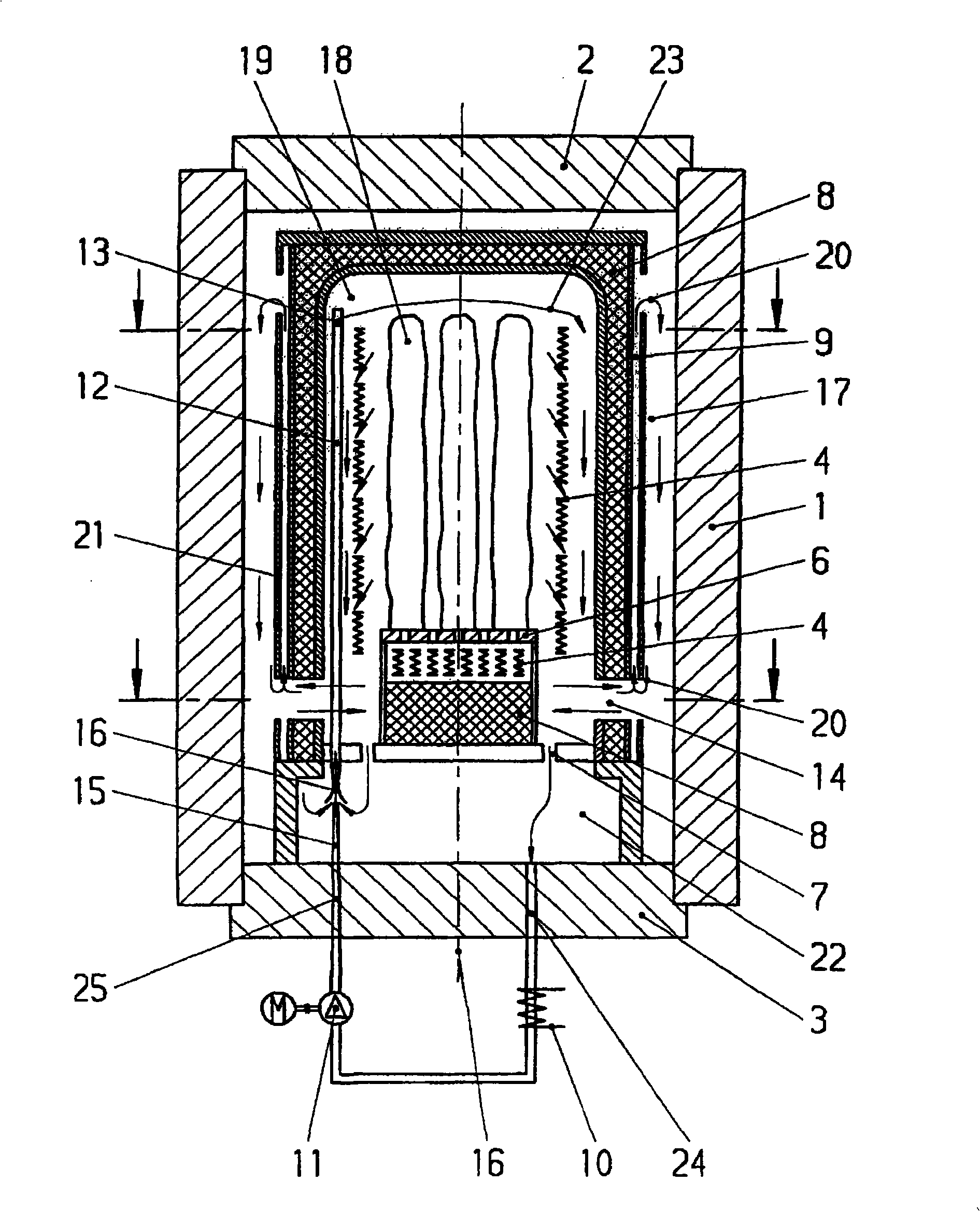

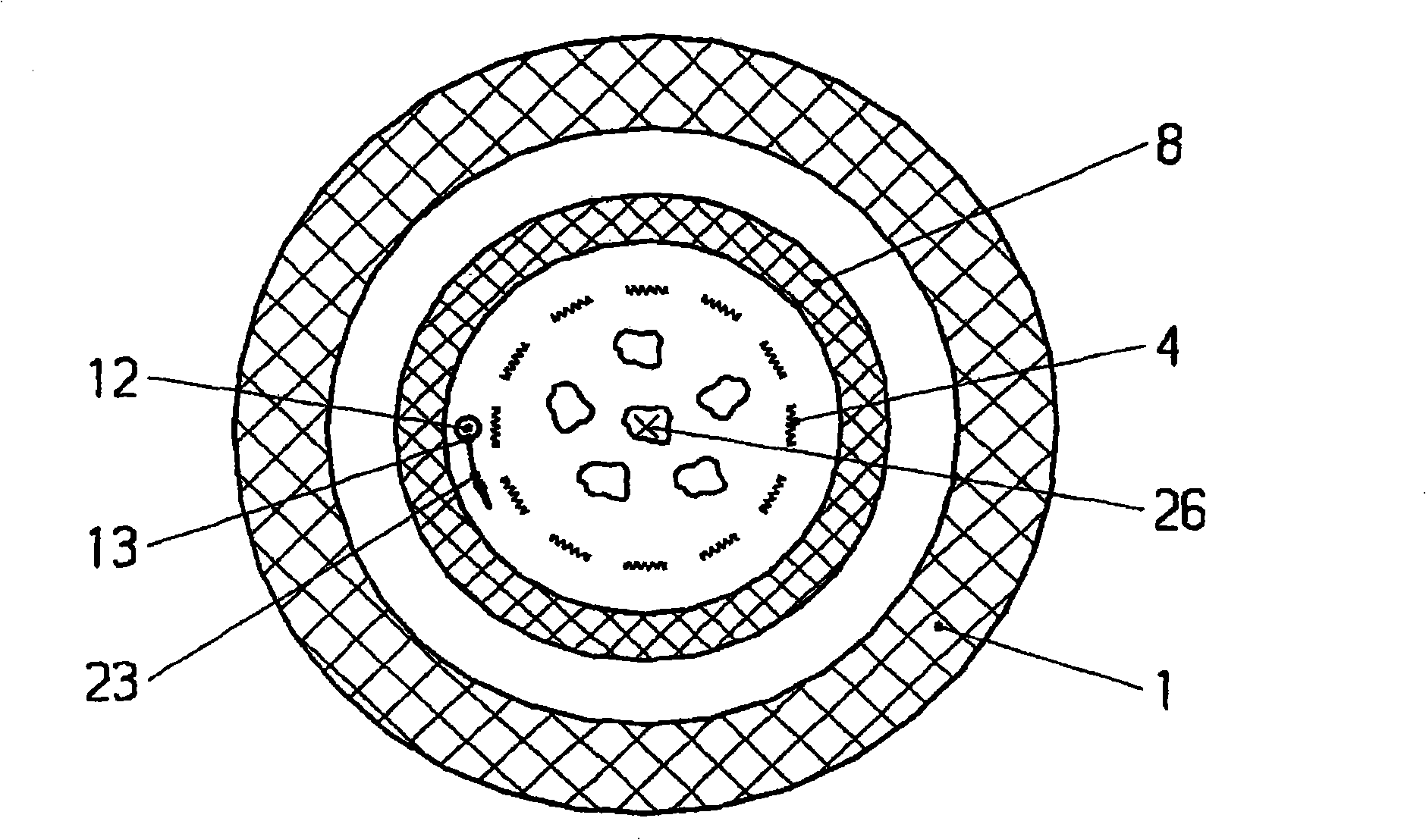

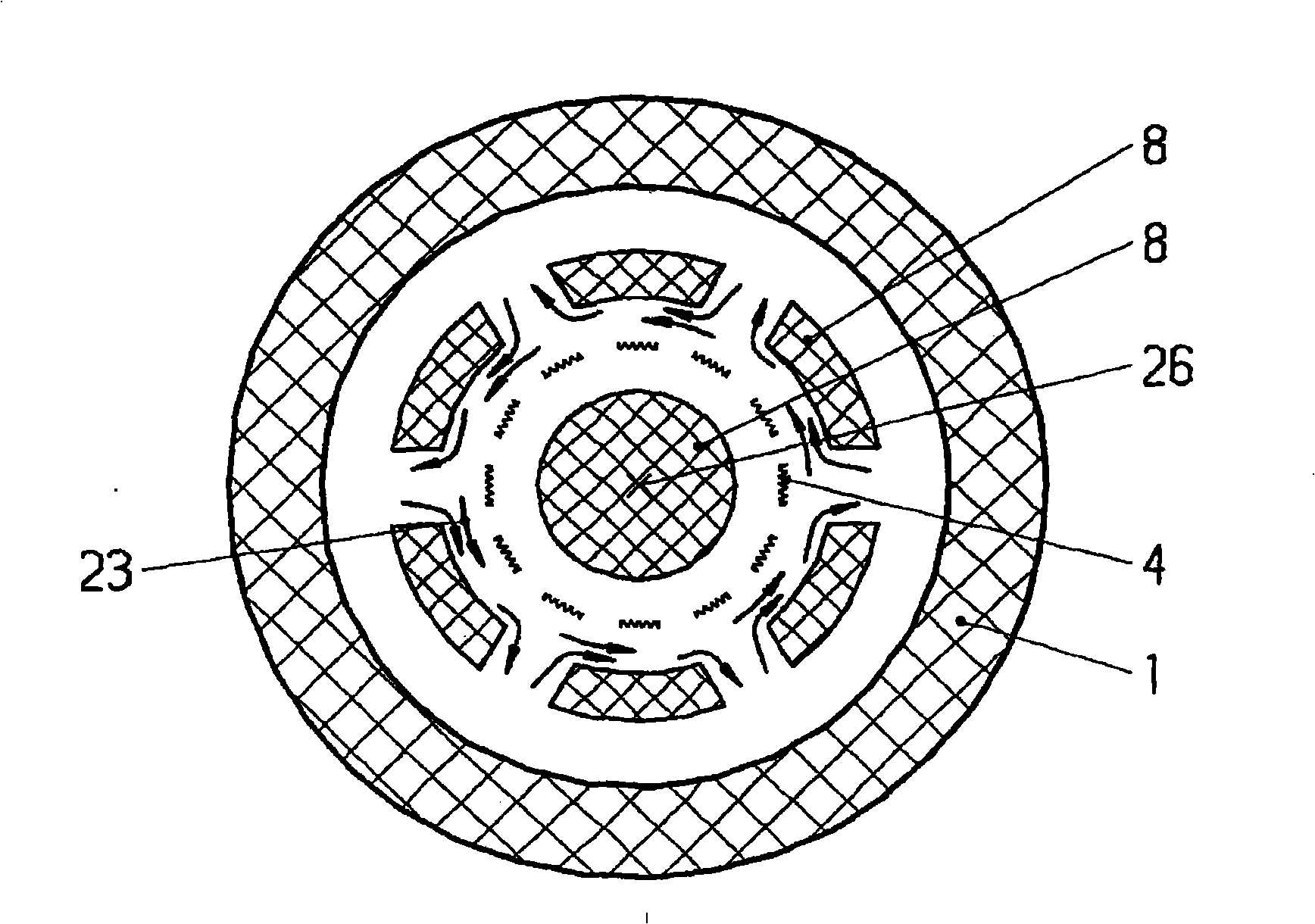

[0018] The pressure vessels 1 shown in these figures each have a generally inner charge zone 19 and a thermal insulation 8 arranged therebetween. The heating element 4 is installed in the insulating body 8, and the charge 18 is usually placed on a charge pallet 6, or it is placed on the charge pallet 6 by means of a bracket (not shown). The pressure vessel 1 also has closing caps 2 and 3 for filling and discharging the pressure vessel, but for the sake of simplicity of description, these are considered to be part of the pressure vessel 1 below. At least one nozzle 13 is installed in the charge area 19 within the area of the heat insulating body 8 , through which a swirling flow 23 is formed, in particular a fluid is injected at high speed. The fluid has a lower temperature than the fluid in the charge zone 19 and / or the charge 18 and is brought into close contact with the inner wall of the insulator 8 by the action of rotation according to the laws of physics. When the swir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com