Opening reinforcement method and reinforcement sheet of fiber reinforcement resin composite material member

A composite material component and fiber reinforced resin technology, which is applied in the field of opening and reinforcement, can solve the problems of long molding die time, difficult quality control, and many processing procedures, and achieve the effects of improving product performance, improving turnover utilization, and reducing processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

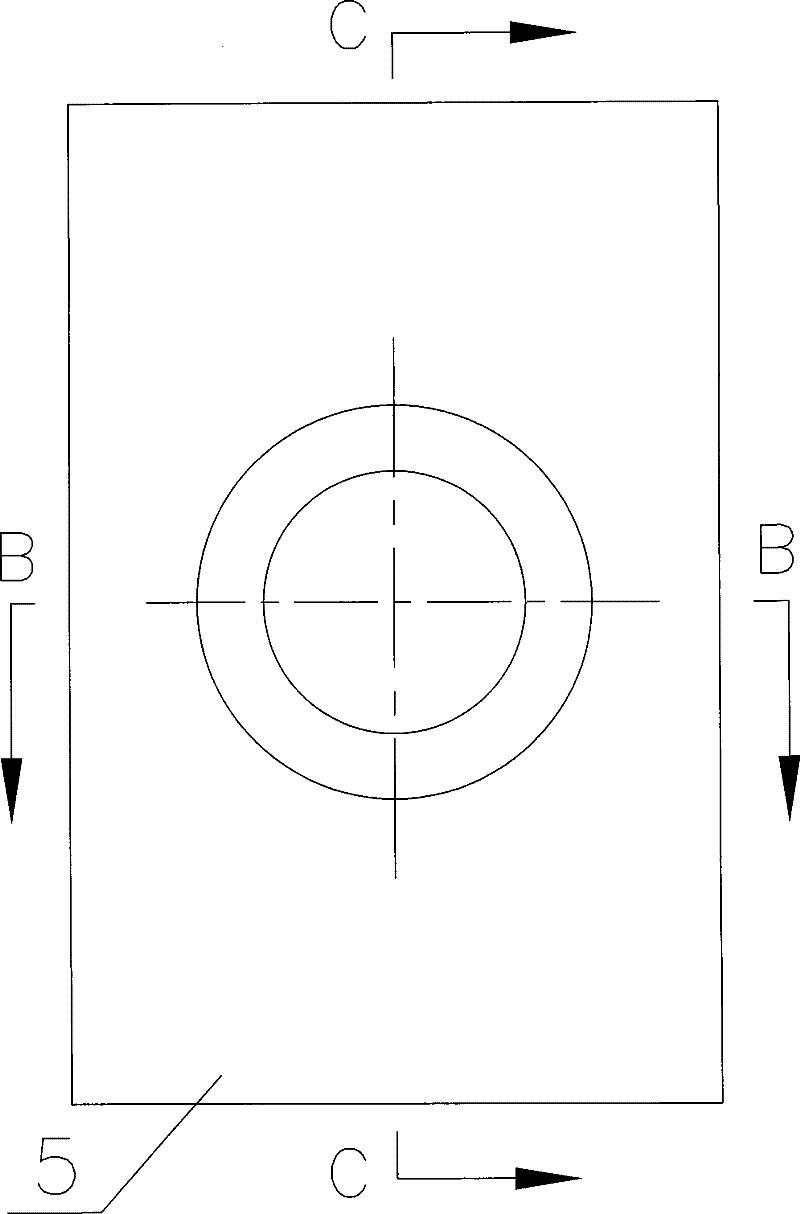

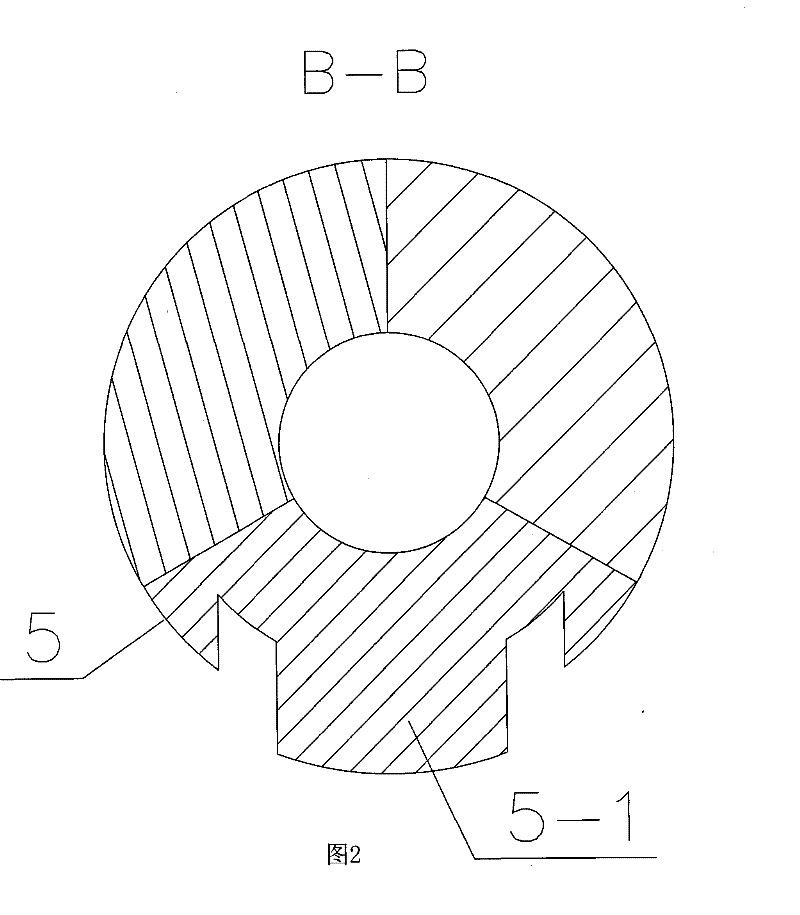

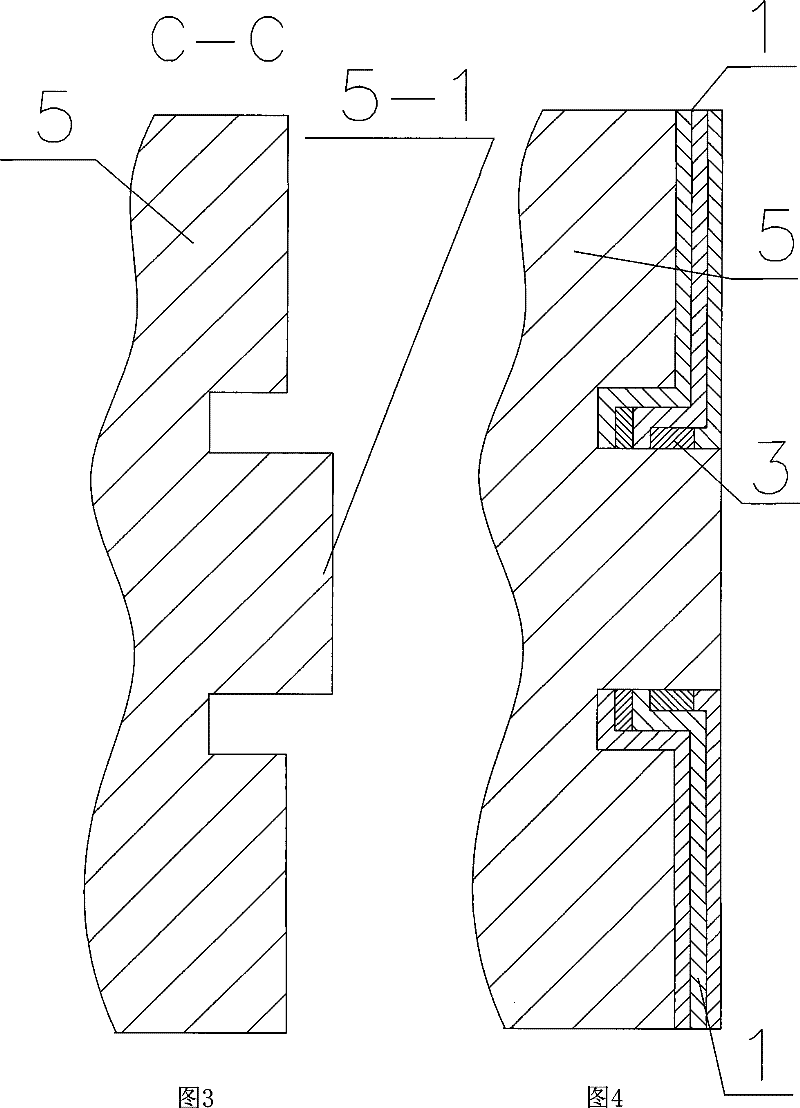

[0007] Specific implementation mode one: as Figure 1-8 As shown, the opening reinforcement method of the fiber-reinforced resin composite material member described in this embodiment is realized according to the following steps: Step 1. Prepare the reinforcement sheet: design the reinforcement sheet according to the size of the opening of the fiber-reinforced resin composite material member According to the geometric shape and size of the designed reinforcing sheet, prepare a reinforcing sheet mold, lay fiber prepreg tape on the mold and perform compaction to obtain the required reinforcing sheet; step 2, Lay a fiber prepreg tape with a thickness L1 of 1.5 to 3 mm on the mandrel 5 for preparing fiber reinforced resin composite components (the single layer thickness of the fiber prepreg tape is 0.15 mm, so 10 to 20 layers need to be laid); Step 3 1. After step 2 is completed, the reinforcing sheet 3 is placed, and the reinforcing sheet is placed on the boss 5-1 of the mandrel ...

specific Embodiment approach 2

[0009] Specific implementation mode two: as Figure 6-8 As shown, the reinforcing sheet in this embodiment is ring-shaped, and the thickness L2 of the reinforcing sheet is 2-4 mm.

specific Embodiment approach 3

[0010] Embodiment 3: The reinforcing sheet described in this embodiment is a fiber axially wound reinforcing sheet. The separately molded reinforcing sheet can realize zero-degree winding molding in the circumferential direction, which can greatly improve the circumferential stiffness of the opening of the fiber-reinforced resin composite member, while other forming methods cannot achieve laying at this angle. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com