Mildewproof dew resisting coating and preparation thereof

An anti-condensation and anti-mildew technology, applied in anti-fouling/underwater coatings, epoxy resin coatings, coatings, etc., can solve the problems of not being effective for a long time, saturated with water absorption, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

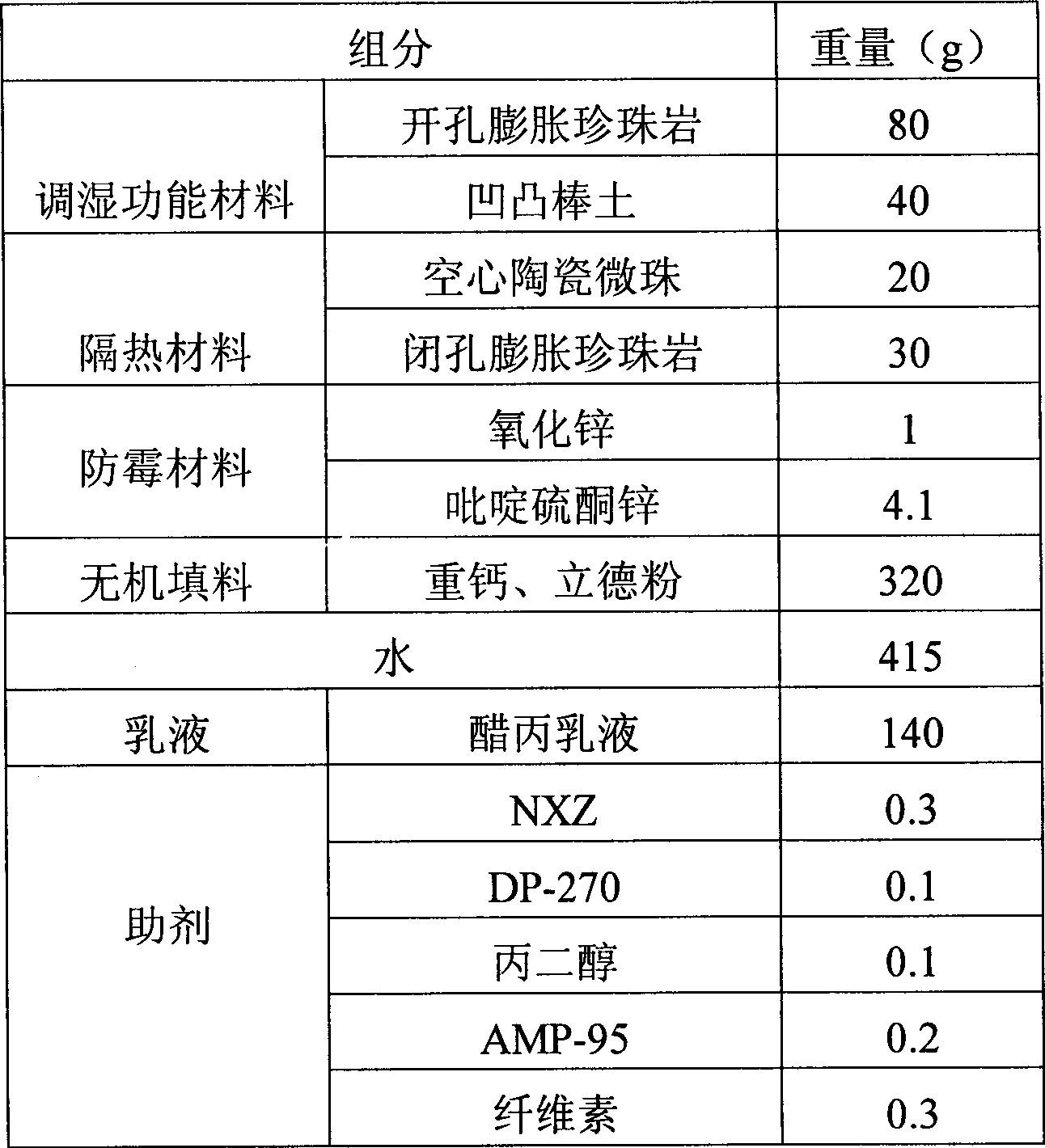

[0038] Embodiment 1: The coating is prepared according to the following proportions.

[0039]

[0040] Use this paint to make a coating, and perform functional testing respectively:

[0041] 1. Hygroscopicity: Make a coating sample with a thickness of 2mm-3mm. After the prepared sample was dried naturally for 24 hours, it was dried in a drying oven at 80°C for 5 hours. Then place it in a humidity-conditioning box to carry out a moisture absorption test, and the test conditions are a temperature of 25° C. and a relative humidity of 85%. After 48 hours, take it out and weigh it. Through the mass calculation before and after the test, it is concluded that the moisture absorption of the sample reaches 280g / m 2 , indicating that the test coating has moisture absorption function; put the moisture-absorbing sample into a humidity-conditioning box with a temperature of 25°C and a relative humidity of 35%, take it out and weigh it after 48 hours, and obtain that the moisture relea...

Embodiment 2

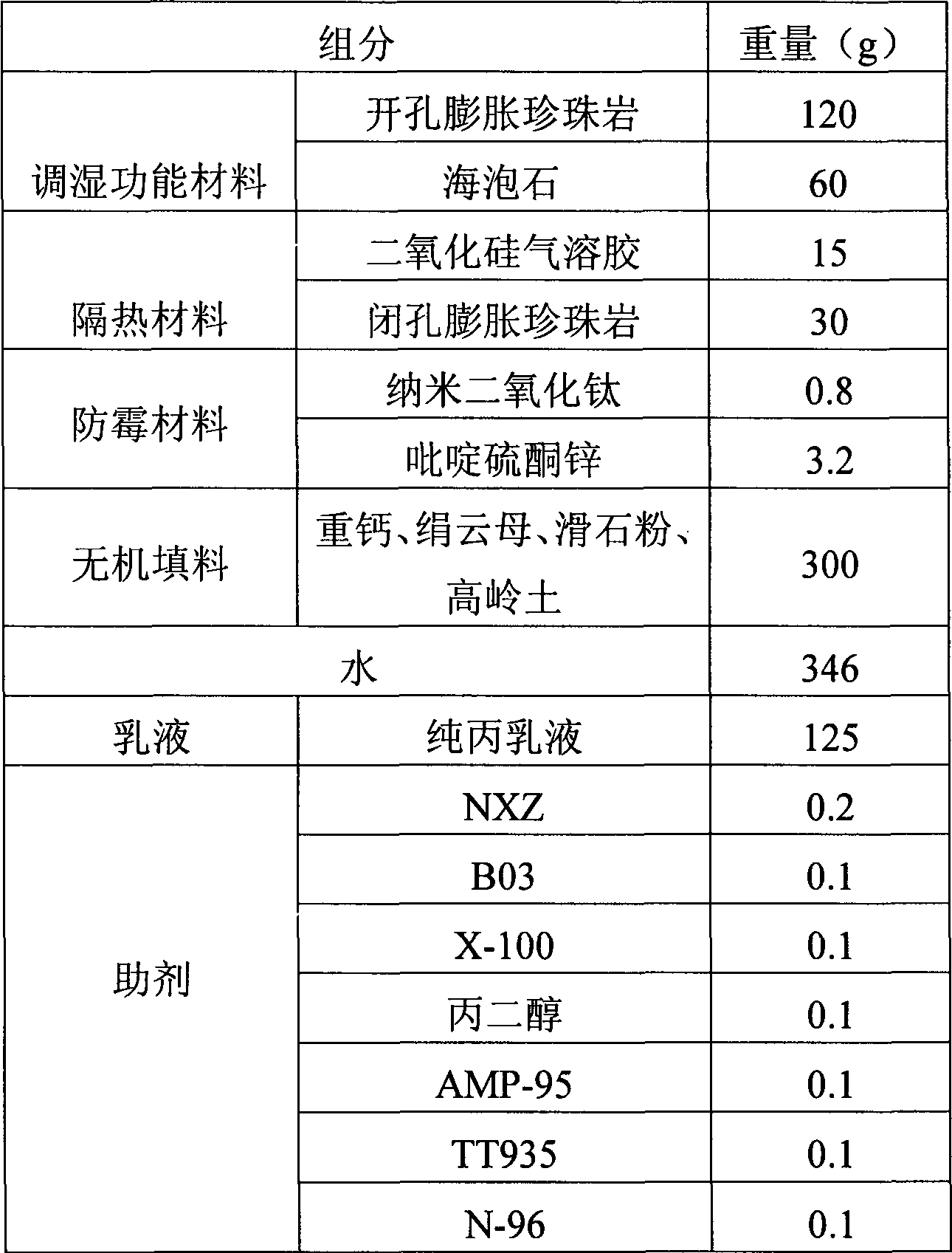

[0044] Embodiment 2: The coating is prepared according to the following proportions.

[0045]

[0046] Carry out functional test with the same method as Example 1, the result: Utilize the coating that this coating is made to test in humidity-conditioning box, under the condition of temperature 25 ℃, relative humidity 85%, moisture absorption reaches 320g / m 2 ;Under the conditions of temperature 25℃ and relative humidity 35%, the moisture release can reach 260g / m 2 , has good moisture absorption and desorption functions; the coating’s killing rate against six comprehensive molds of Candida albicans and Aspergillus niger has reached level 0; the killing rate against Staphylococcus aureus and Escherichia coli are respectively: 99.9% and 99.9%; the thermal conductivity of the coating measured by the coating thermal conductivity tester is 0.040W / m·K.

Embodiment 3

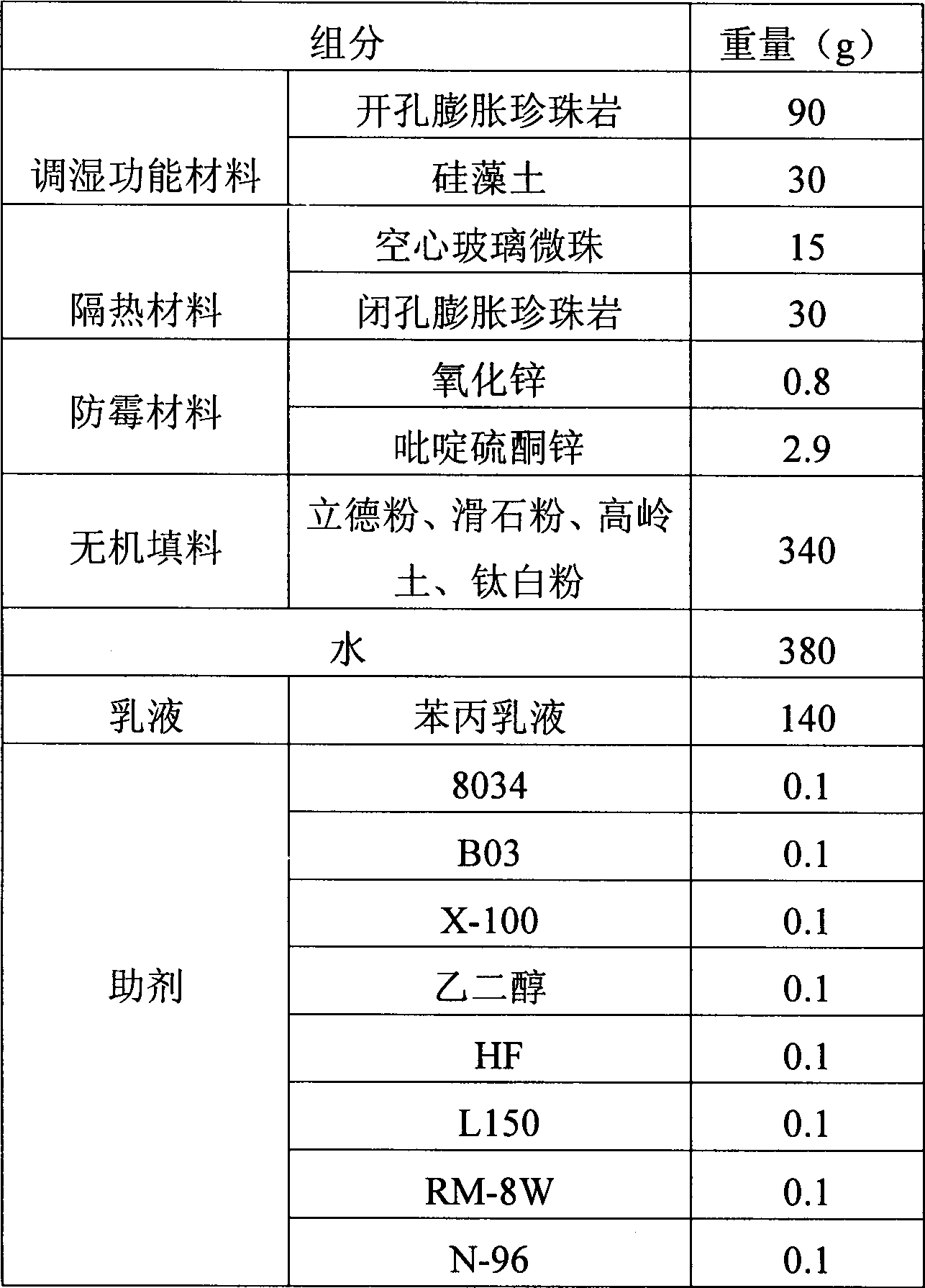

[0047] Embodiment 3: Prepare the coating according to the following proportions.

[0048]

[0049] Carry out functional testing with the same method as in Example 1, the result: the coating made of this coating is tested in a humidity-conditioning box, and the moisture absorption reaches 330g / m at a temperature of 25°C and a relative humidity of 85%. 2 ;Under the conditions of temperature 25℃ and relative humidity 35%, the moisture release can reach 259g / m 2 . The coating's killing rate against Candida albicans and Aspergillus niger reached grade 0, and its antibacterial performance against Staphylococcus aureus and Escherichia coli was 98.9% and 99.9% respectively. The coating thermal conductivity tester measured the thermal conductivity of the coating to be 0.039W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com