Gear drive system of engine

A technology of gear transmission and engine, which is applied in the field of gear transmission system, can solve the problems of larger engine size, larger engine axial size, and lower reliability, and achieve improved reliability, simple and reliable positioning, and compact layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

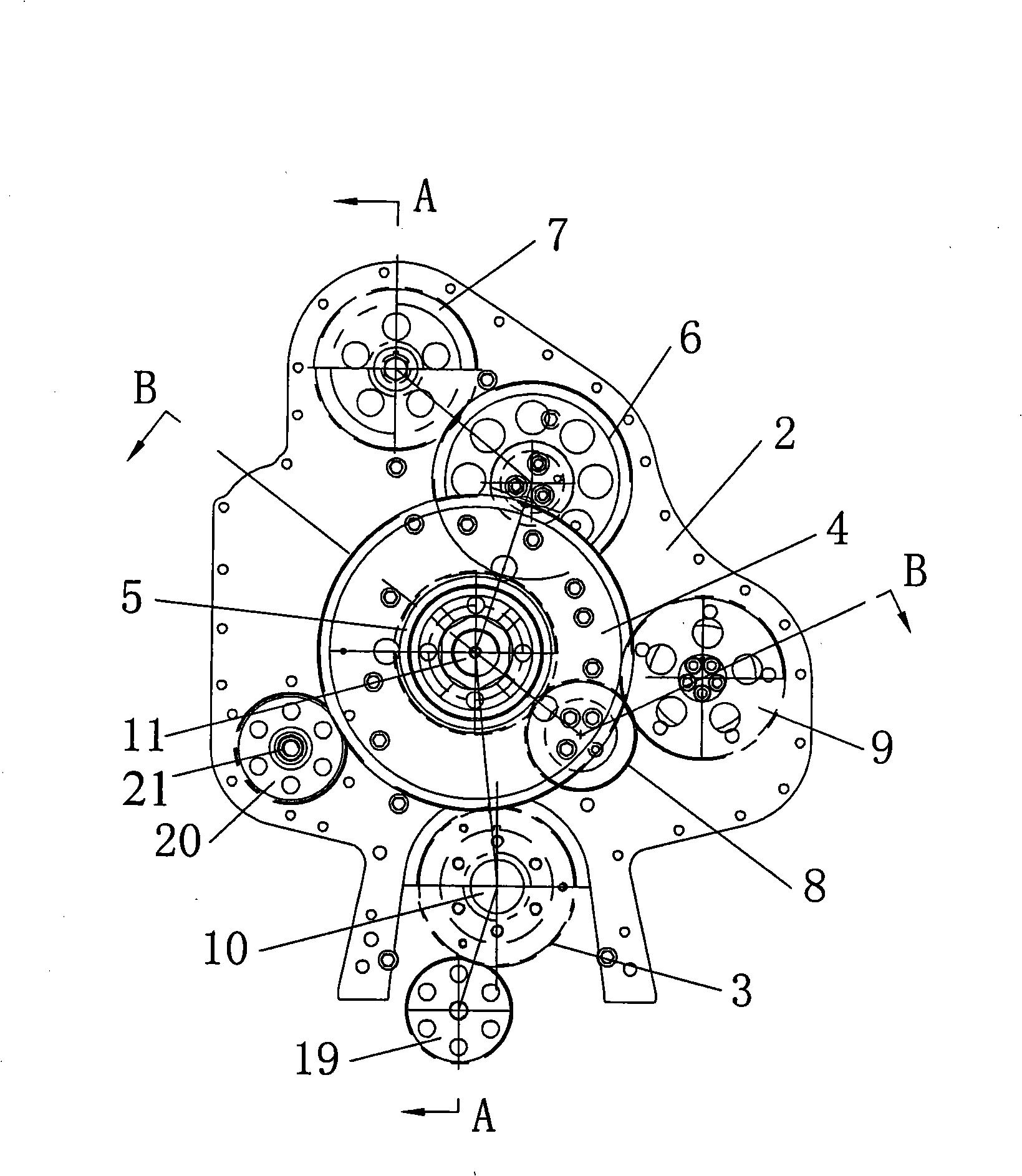

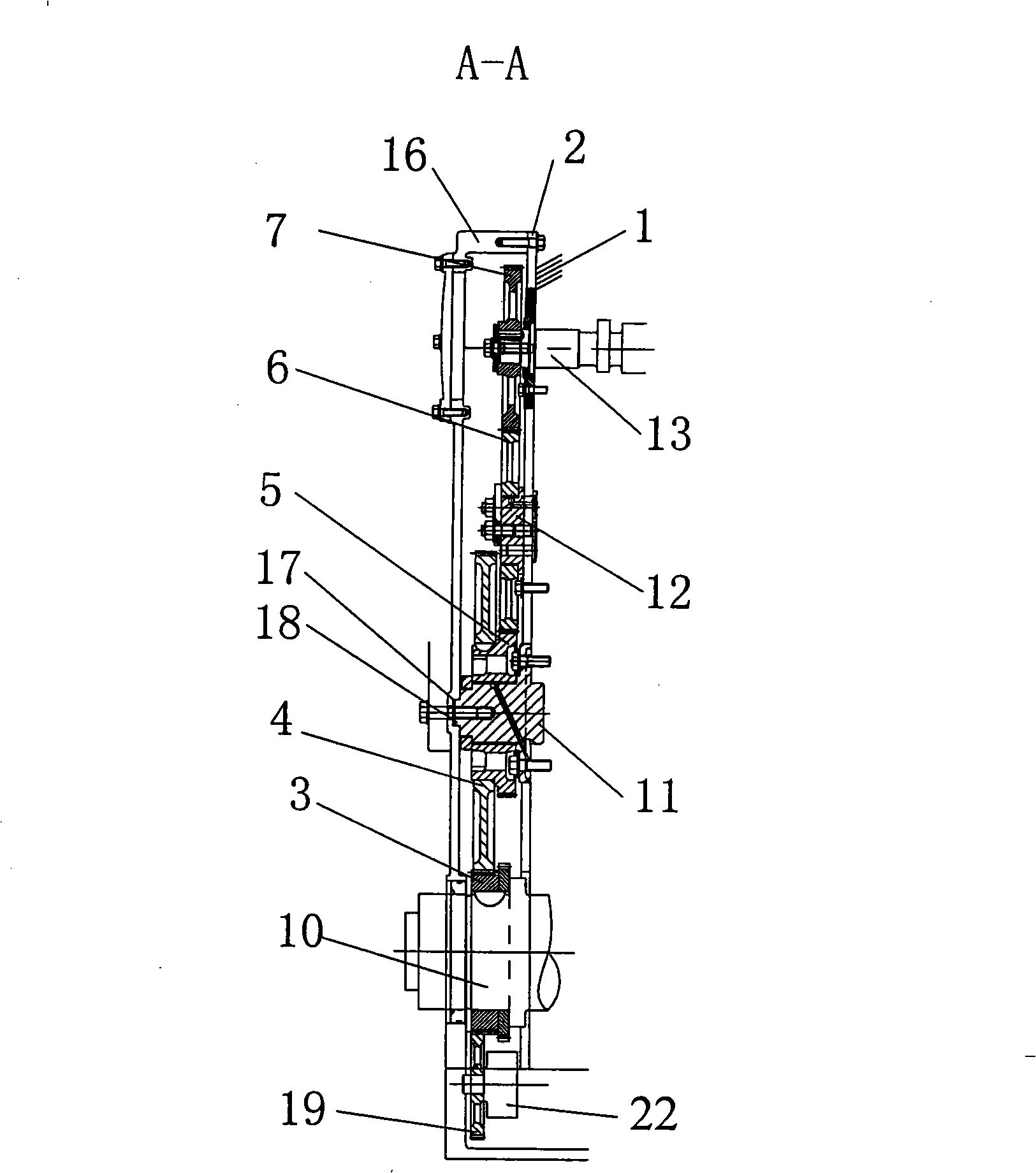

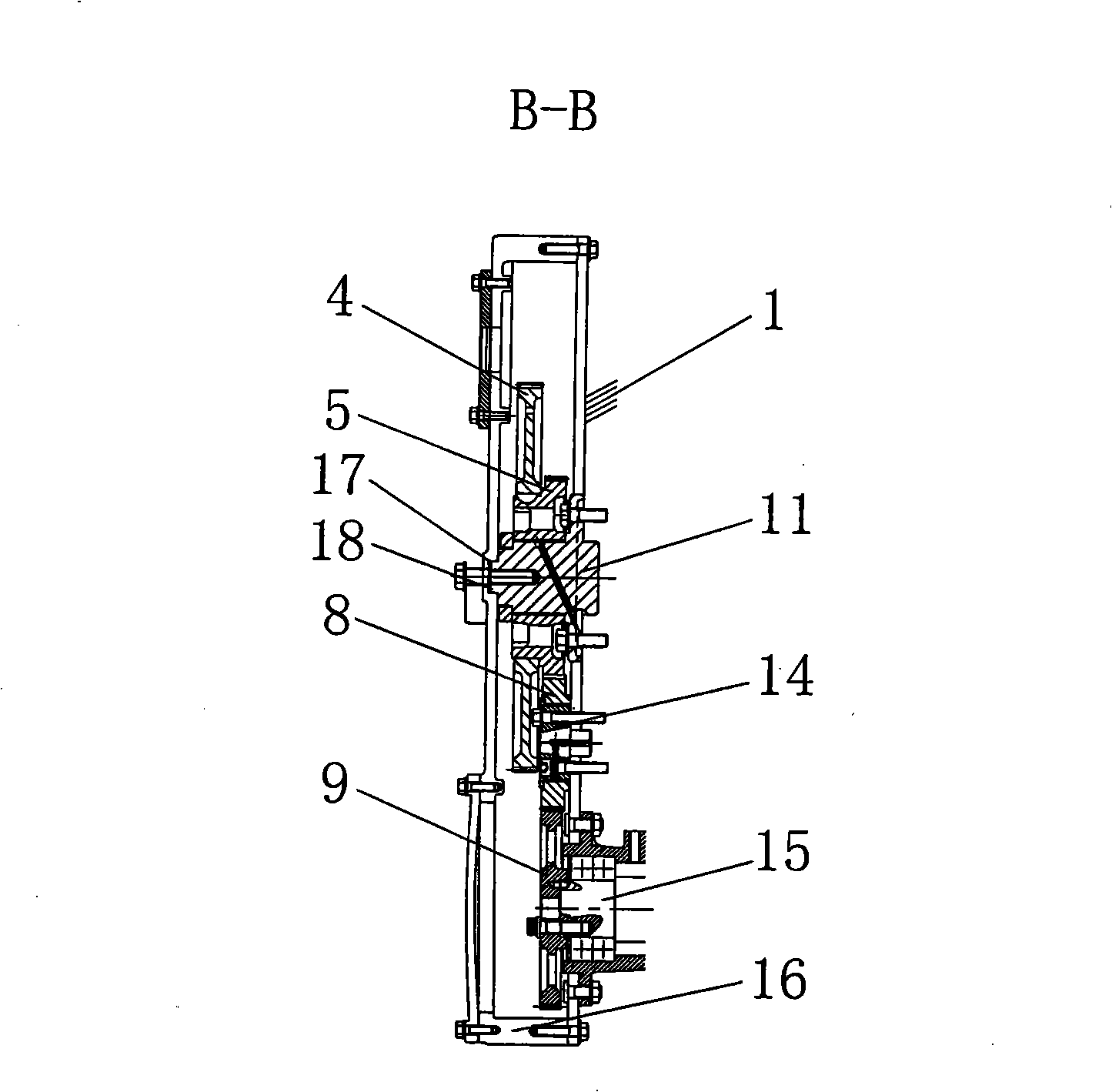

[0016] Figure 1 ~ Figure 3 As shown, it includes body 1, bottom plate 2, crankshaft timing gear 3, bull gear 4, pinion gear 5, first idler gear 6, camshaft driving gear 7, second idler gear 8, fuel injection pump gear 9, crankshaft 10, Central shaft 11, first idler gear shaft 12, camshaft 13, second idler gear shaft 14, output shaft 15, gear chamber cover 16, concave hole 17, shaft head 18, oil pump drive gear 19, water pump drive gear 20, The water pump drive shaft 21 and the oil pump drive shaft 22 .

[0017] Such as Figure 1 ~ Figure 3 As shown, the base plate 2 of the present invention is fixed on the front end face of the engine body 1, the crankshaft 10 is installed in the body 1, the crankshaft timing gear 3 is installed on the crankshaft 10, and the central shaft 11 and the first idler are respectively installed on the base plate 2 by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com