Steam generator

A steam generator and steam outlet technology, applied in the field of mechanical equipment, can solve the problems of large coal resource consumption, low heat energy utilization rate, and low heat exchange efficiency, and achieve small footprint, high safety, and high heat transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

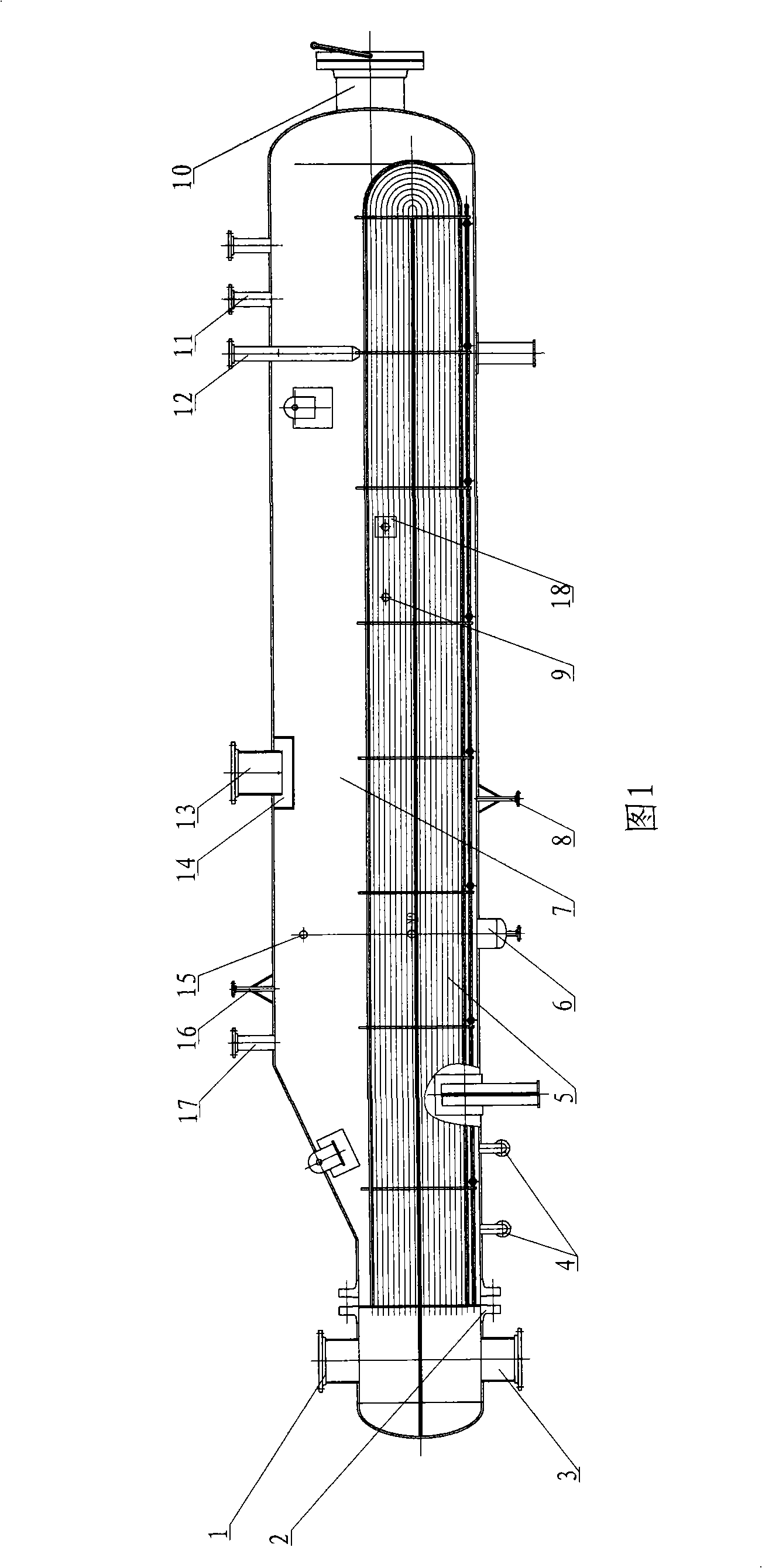

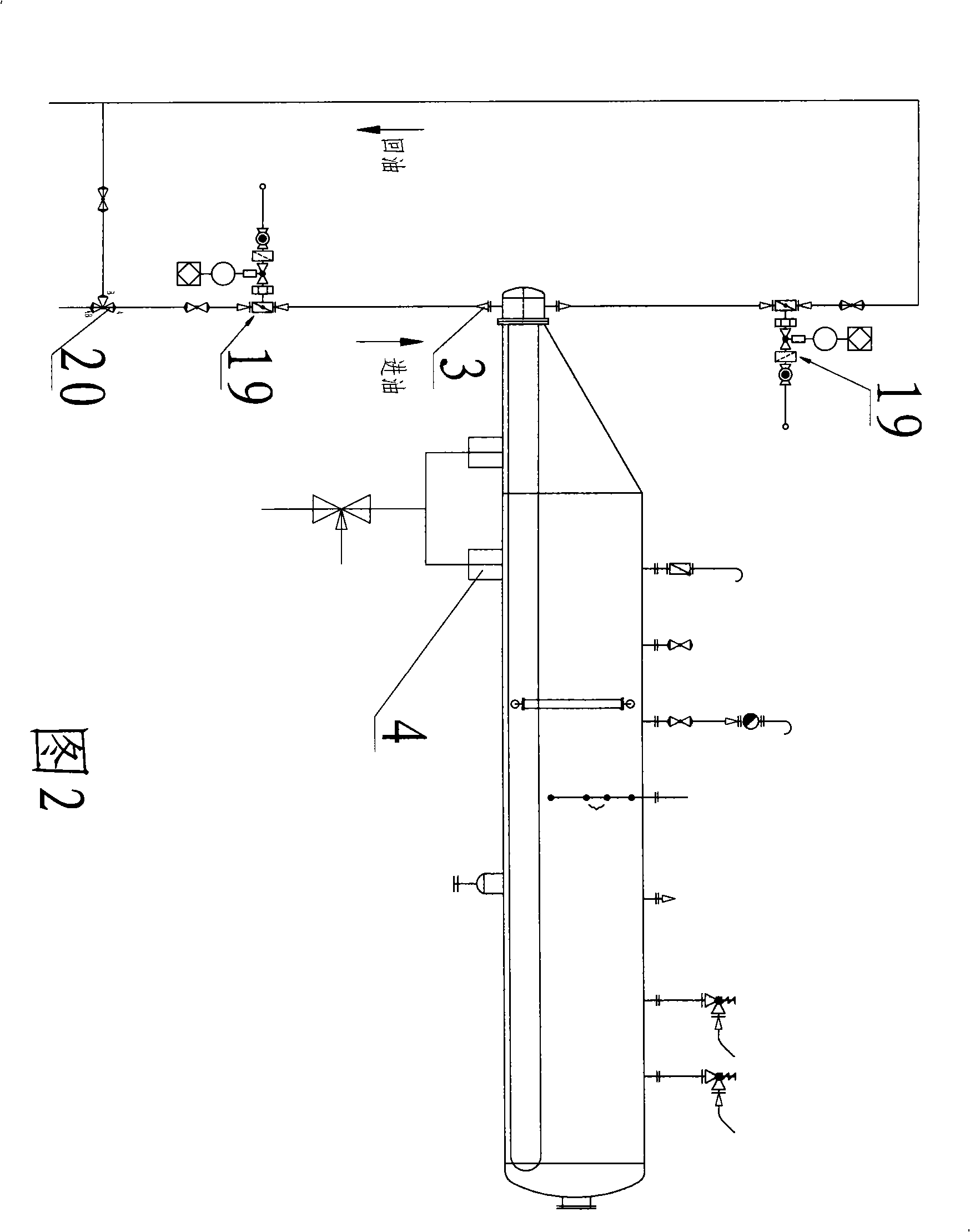

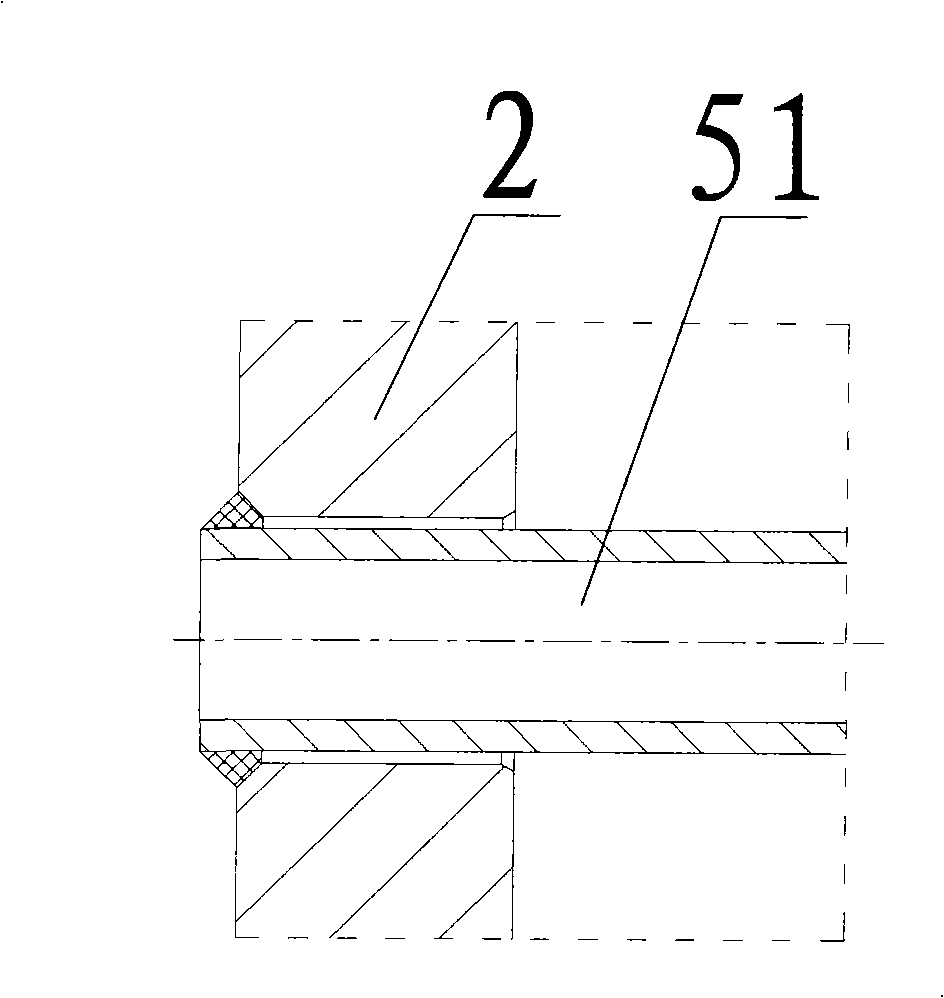

[0023] Referring to the accompanying drawings, the steam generator of the present invention has a housing 7 that adopts a 16MnR steel plate, and the housing 7 is provided with an oil inlet 3, an oil outlet 1, a water inlet 4, a water outlet 8, and is connected with a steam-water separator 14 The steam outlet 13 and the manhole 10 for people to enter the interior of the casing for inspection and maintenance can be used for people through the device. The water inlet 4 is arranged on the side of the housing 7 close to the oil inlet 3 . A sewage outlet 6 is arranged below the housing 7 . The side wall of the casing 7 is provided with a brine outlet 9 . The shell 1 is provided with a tube plate 2 made of 16MnR steel plate, and the tube plate 2 is fixed with a tube bundle composed of a heat-conducting oil tube 51 made of a seamless steel pipe produced in accordance with GB3087, which communicates with the oil outlet 1 and the oil inlet 3 5.

[0024] A safety valve 11 , a liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com