Safe blasting system capable of alarming misfire information

A blind and safe technology, applied in the field of blasting, can solve problems such as digital detonators cannot be detected, charge failure, casualties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

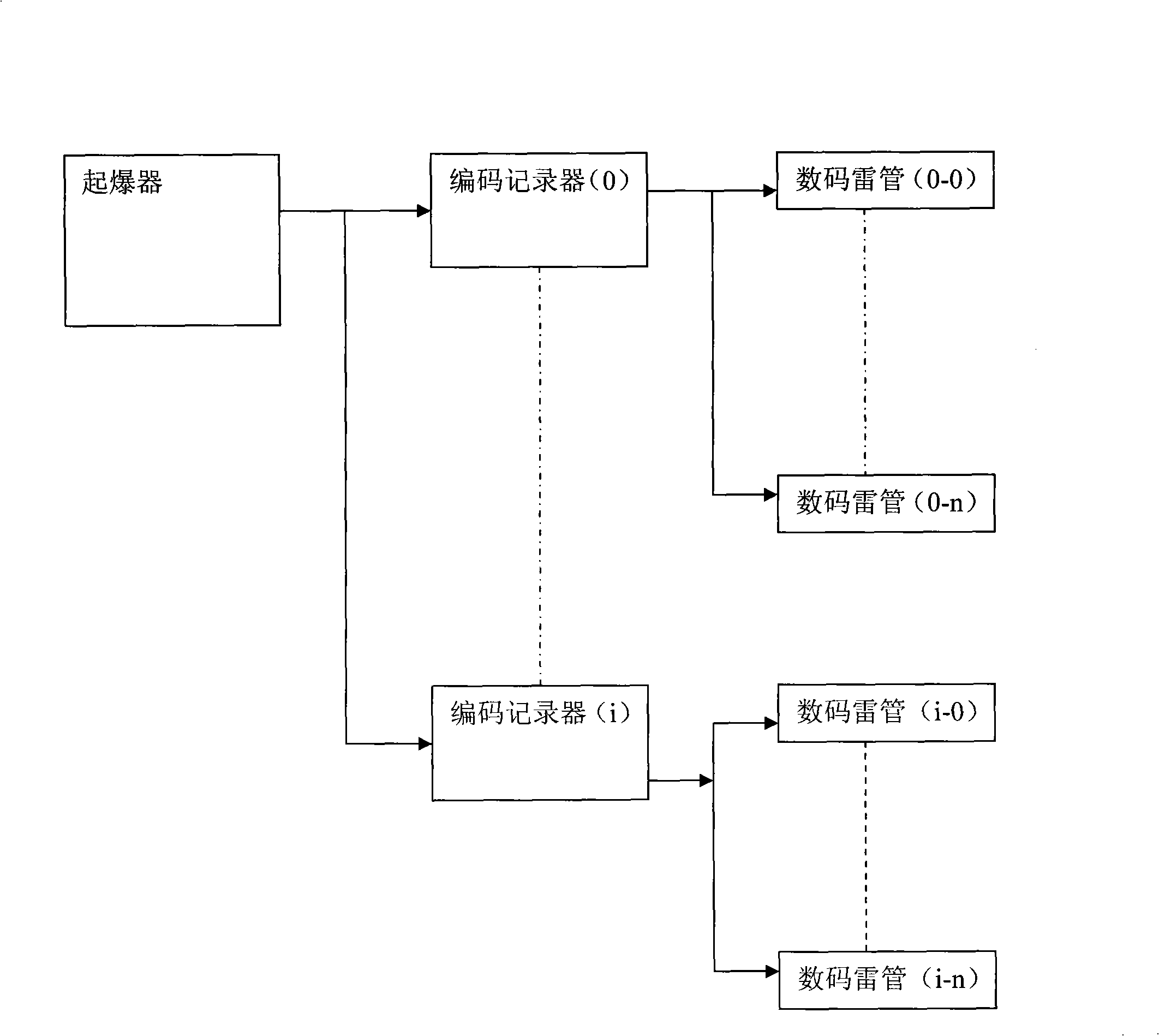

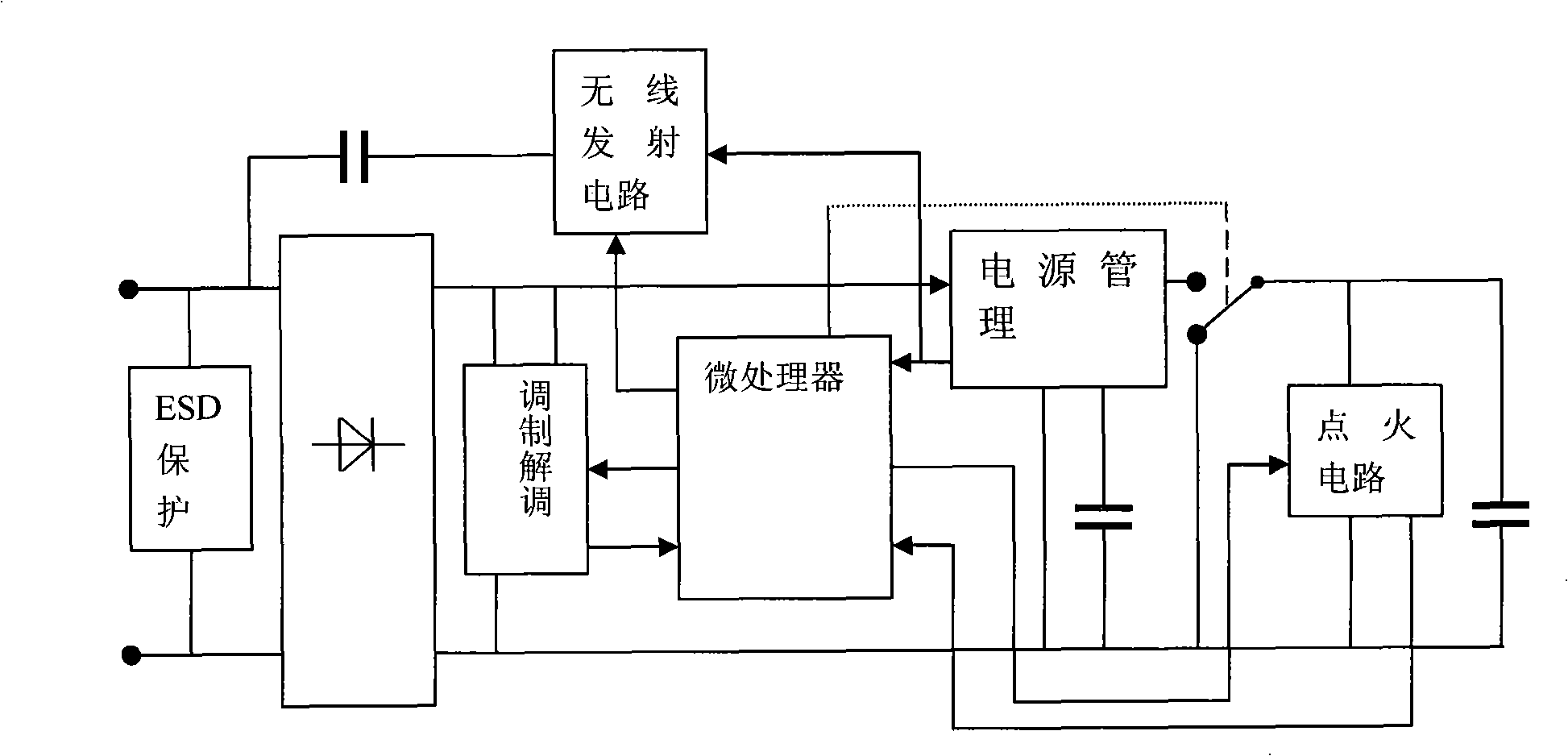

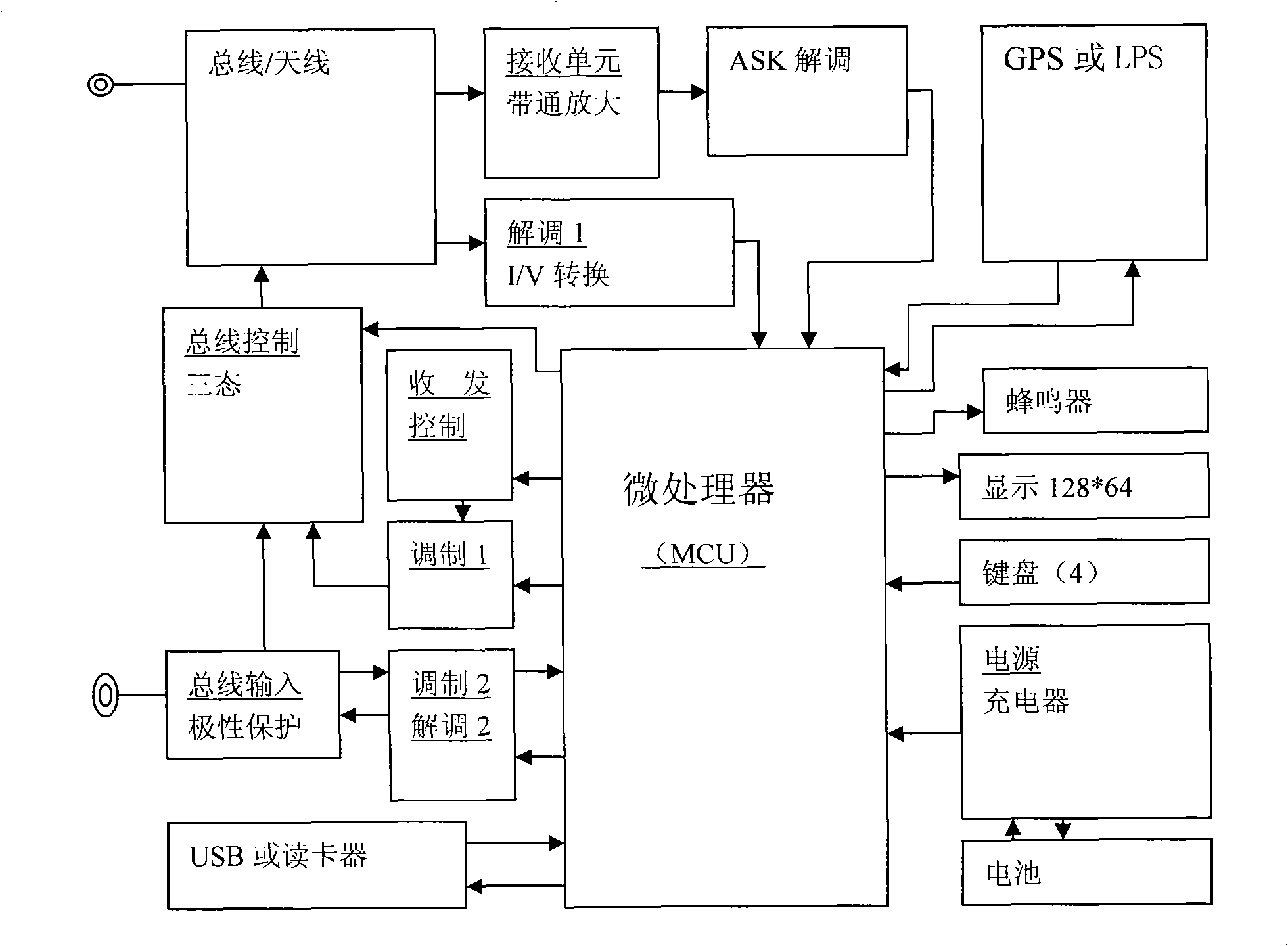

[0023] In the following preferred specific embodiments, the present invention provides a safety blasting system that assists in the positioning of detonators that fail to detonate and that can warn of false fire information. The device utilizes the Global Positioning System (GPS) or Local Positioning System (LPS), which provide useful reference information for locating unexploded detonators and explosives.

[0024] The present invention provides an important improvement in safety in the blasting industry. The present invention extends the control of blasting faults from just before blasting to the entire process of blasting operations. In preferred embodiments, the invention may involve intercommunication between components of blasting equipment, or between associated detonators, or between components of blasting equipment and associated detonators, such intercommunication may involve electronic or wireless communication . In this way, at least in specific embodiments, the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com