Method and device for measuring piston ring excircle configuration multiple parameters

A measuring device and measuring method technology, applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic profile/curvature measurement, etc., can solve the problems affecting the quality assurance of piston rings, cannot be used in the production site, and the measuring device is expensive, etc. Achieve the effect of fast detection speed, high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

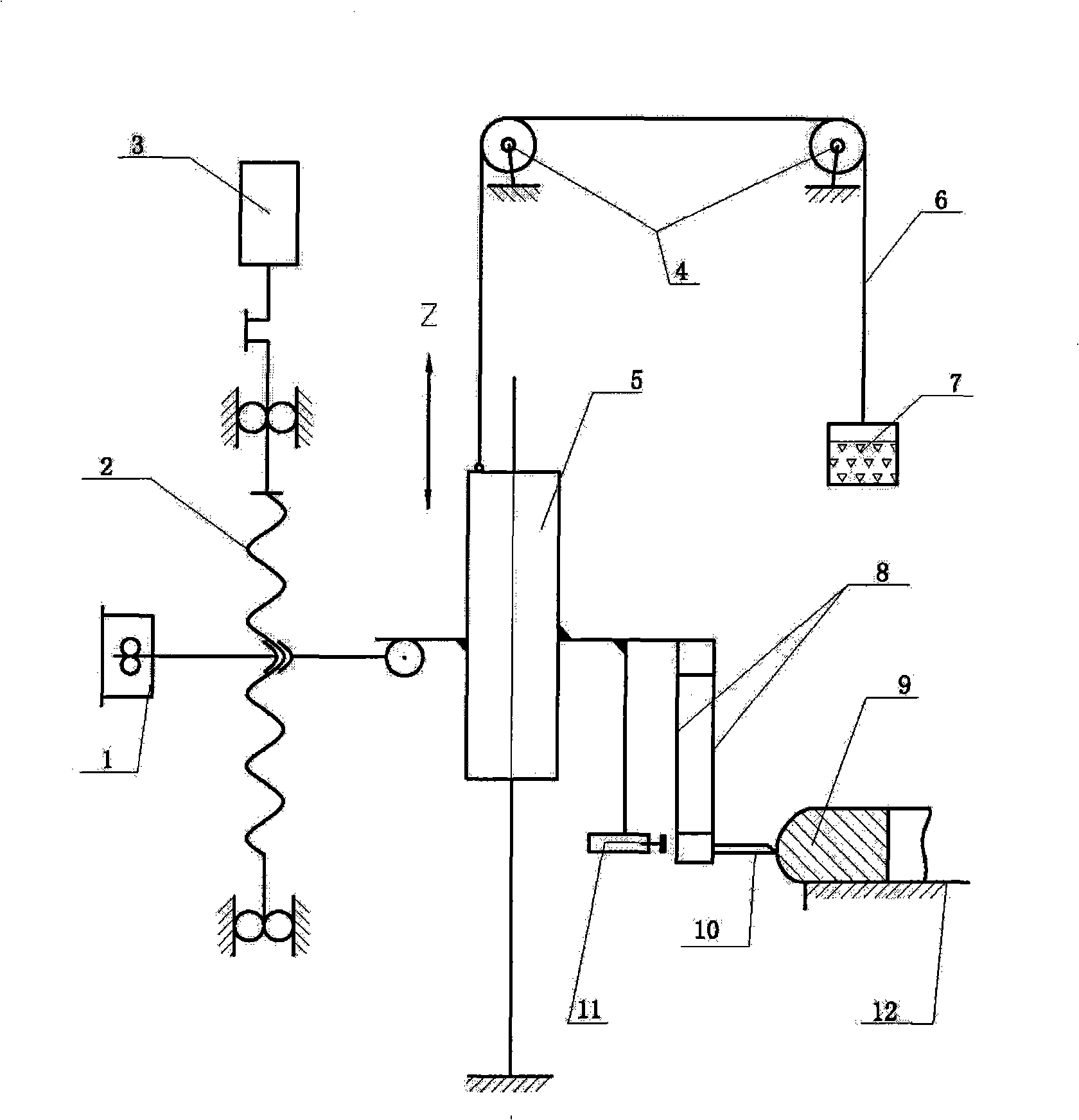

[0053] Embodiment 1 - multi-parameter measuring device for outer circle profile of piston ring

[0054] The measuring device for measuring and describing the multi-parameters of the outer circle profile of the piston ring provided by the present invention includes the measuring head clamped on the workbench 12 to be measured by the piston ring 9, and the measuring head is driven by its guide rail sleeve to move along the Z direction The air-floating guide rail 5 and the stepper motor 3 that drives the air-floating guide rail cover to move through the screw drive pair 2. The transmission connection between the screw drive and the air-floating guide rail cover adopts a point contact transmission connection, and the nut forming the screw drive pair is designed with an anti-rotation guide block 1 . The air flotation guide rail is a surface throttling gas static pressure air flotation guide rail with a movement accuracy of 0.1 μm. The measuring head is composed of a parallel leaf ...

Embodiment 2

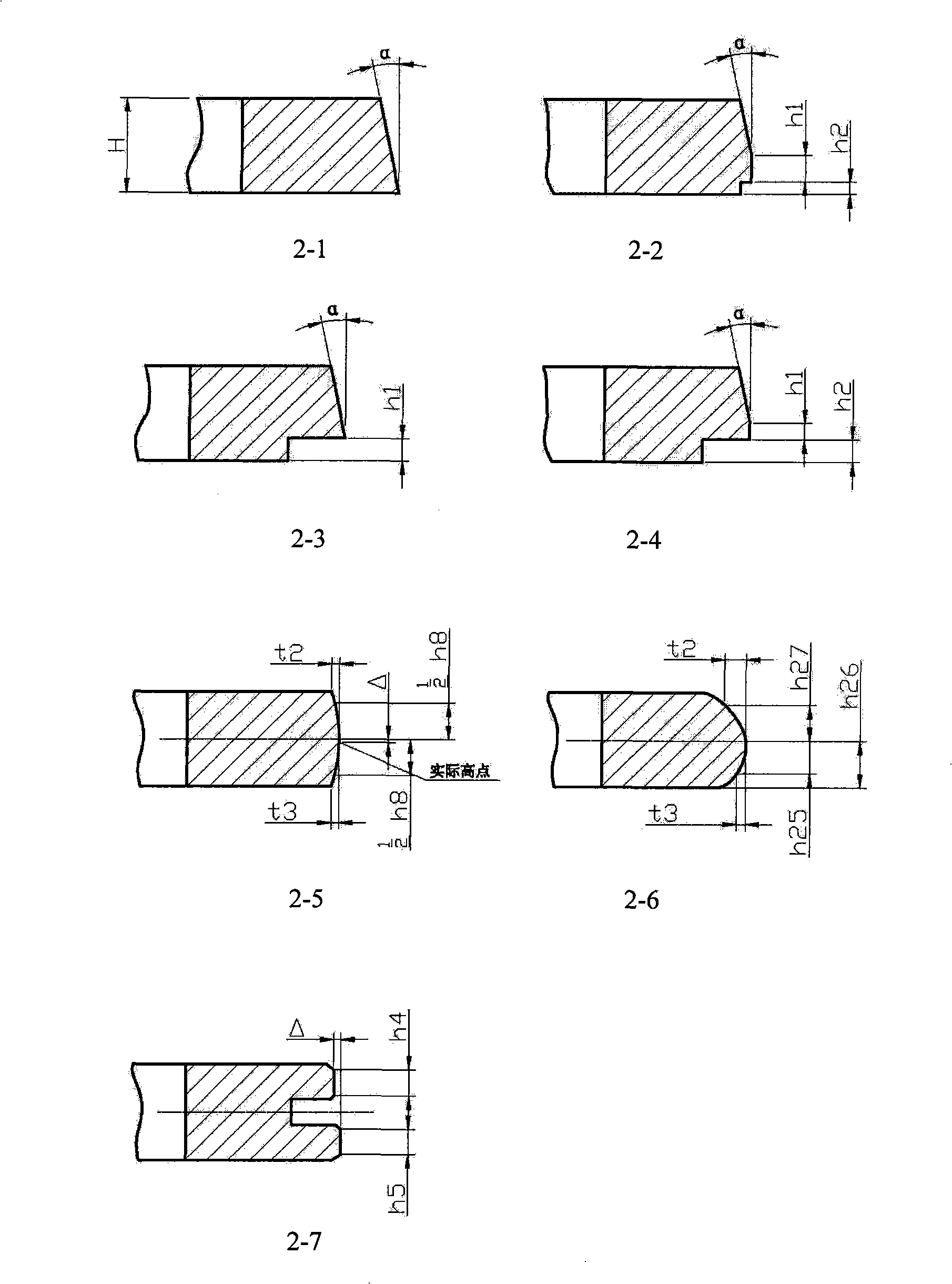

[0055] Embodiment 2 - multi-parameter measurement method of piston ring outer circle profile

[0056] In this embodiment, the second type of tapered ring with a platform is used as the measurement object. The main parameters describing the outer circle profile of the piston ring are the outer circle slope α (bevel angle) of the ring, the straightness of the generatrix and the platform height h1, which are the parameters of the outer circle profile of the piston ring to be measured in this embodiment.

[0057] In this embodiment, the method for measuring the multi-parameters of the outer circular contour of the second type of tapered ring with a platform includes the following measurement steps:

[0058] (1) The second type of tapered ring with platform to be measured is clamped on the workbench of the piston ring outer circle profile multi-parameter measuring device provided in embodiment 1;

[0059] (2) The type of the piston ring to be tested - the second type of tapered ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com