System for measuring high temperature moire interference deformation

A moiré interference and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems that the temperature field has a great influence on the measurement optical path, the imaging distance is short, and the position of the test piece cannot be adjusted, and the structure is compact, Increased imaging distance and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

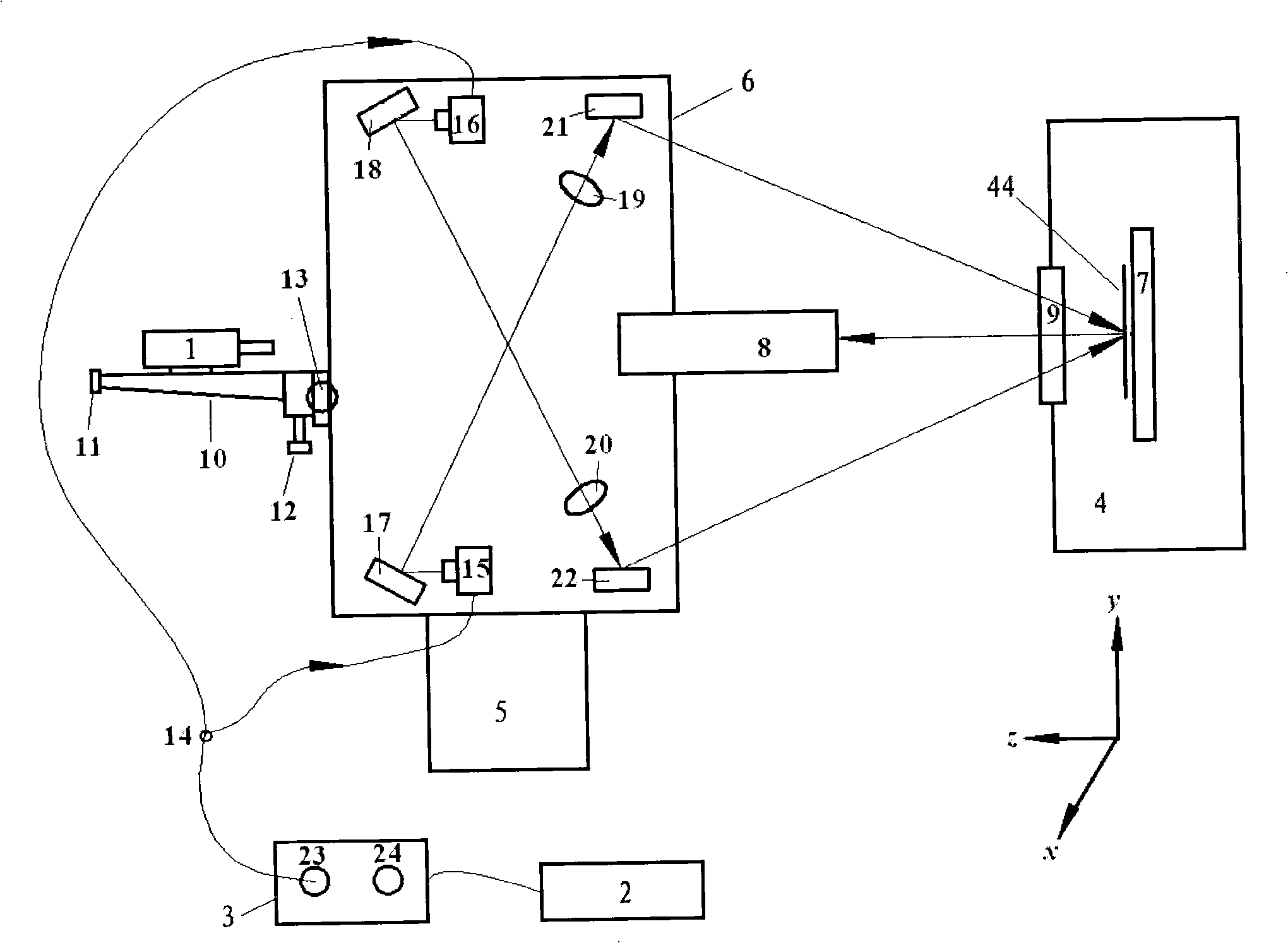

[0023] Such as figure 1 As shown, the high-temperature moiré interference deformation measurement system of the present invention is mainly composed of an image acquisition system 1, a laser 2, an optical coupler 3, a high-temperature furnace 4 with an observation window, a six-dimensional adjustment frame 5, and a moiré interference optical path system Composition, all installed on a test bench. The moiré interference optical path system includes a moiré interference optical element box 6 , a lens 8 and a grating 44 . The moiré interference optical element box 6 is integrated into a dark box, which is fixed on the test bench through a six-dimensional adjustment frame 5 . The image acquisition system 1 is fixed on the moiré interference optical element box 6 by a three-dimensional adjustment frame 10 and screws, and the image acquisition system 1, the lens 8 and the grating 44 are located on the same straight line. The grating 44 is pasted on the surface of the test piece 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com