Electrical junction box

A technology for electrical junction boxes and printed circuit boards, which is applied in the directions of circuits, connections, electrical components, etc., can solve the problems of increased size and high cost of electrical junction boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

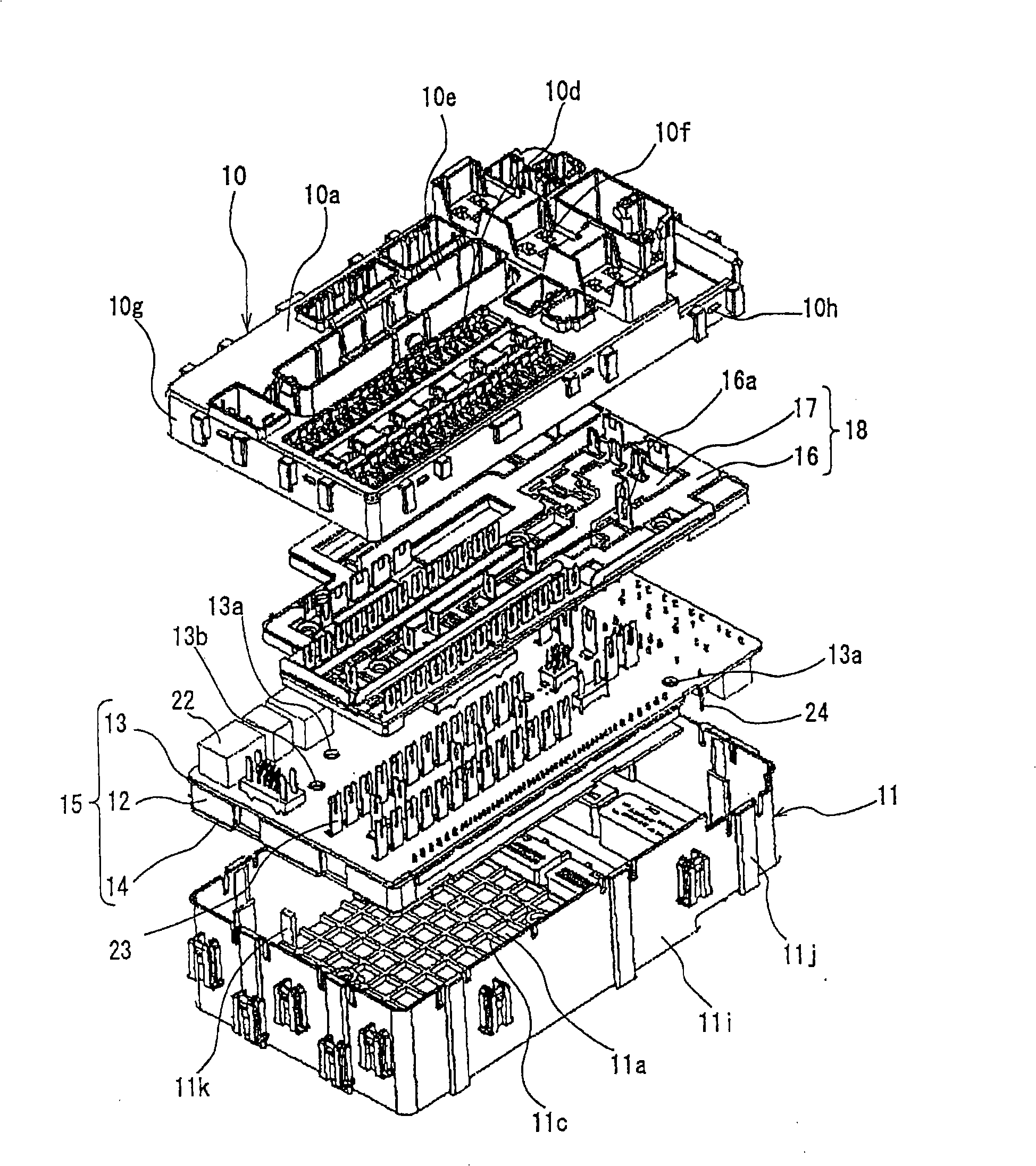

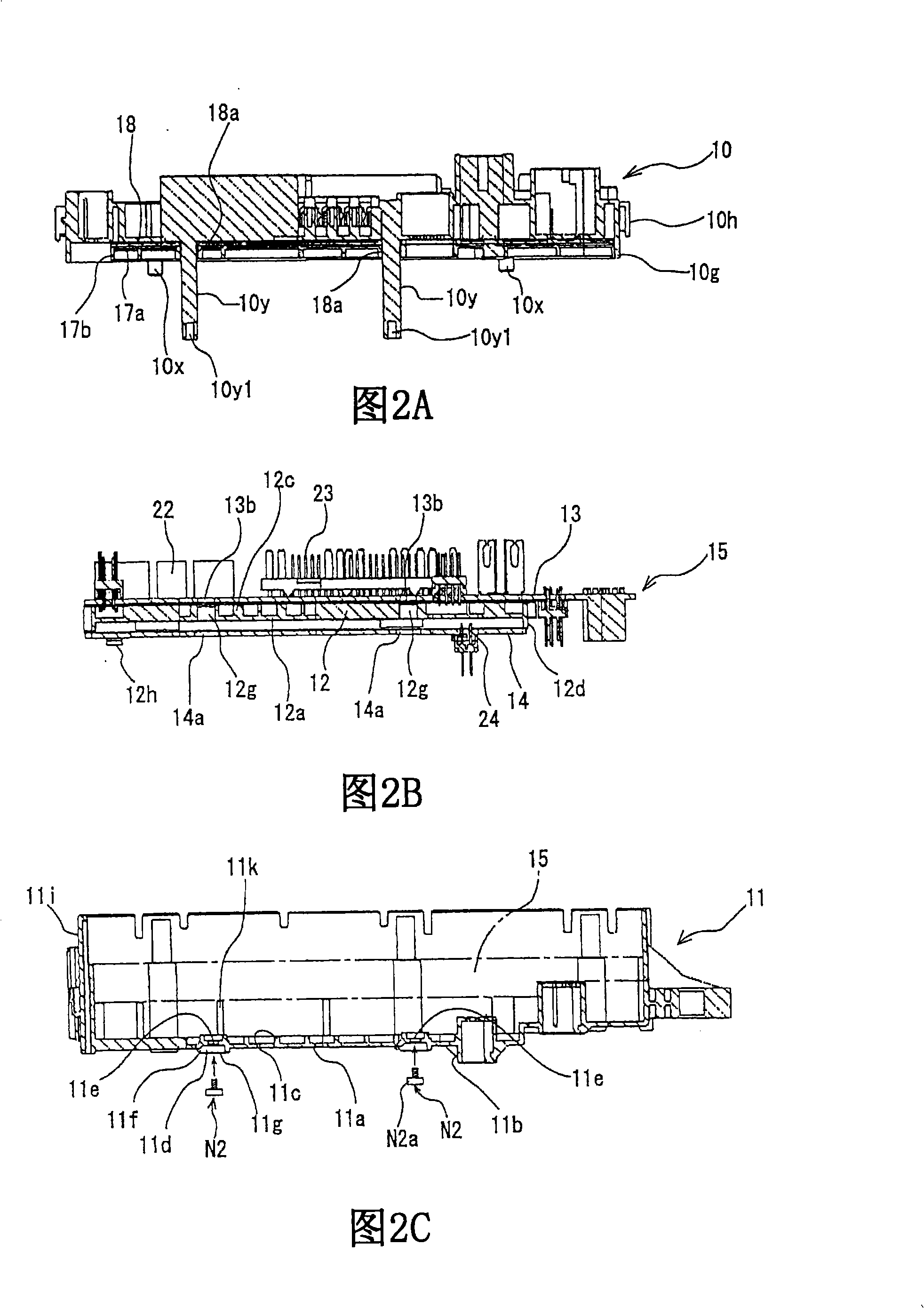

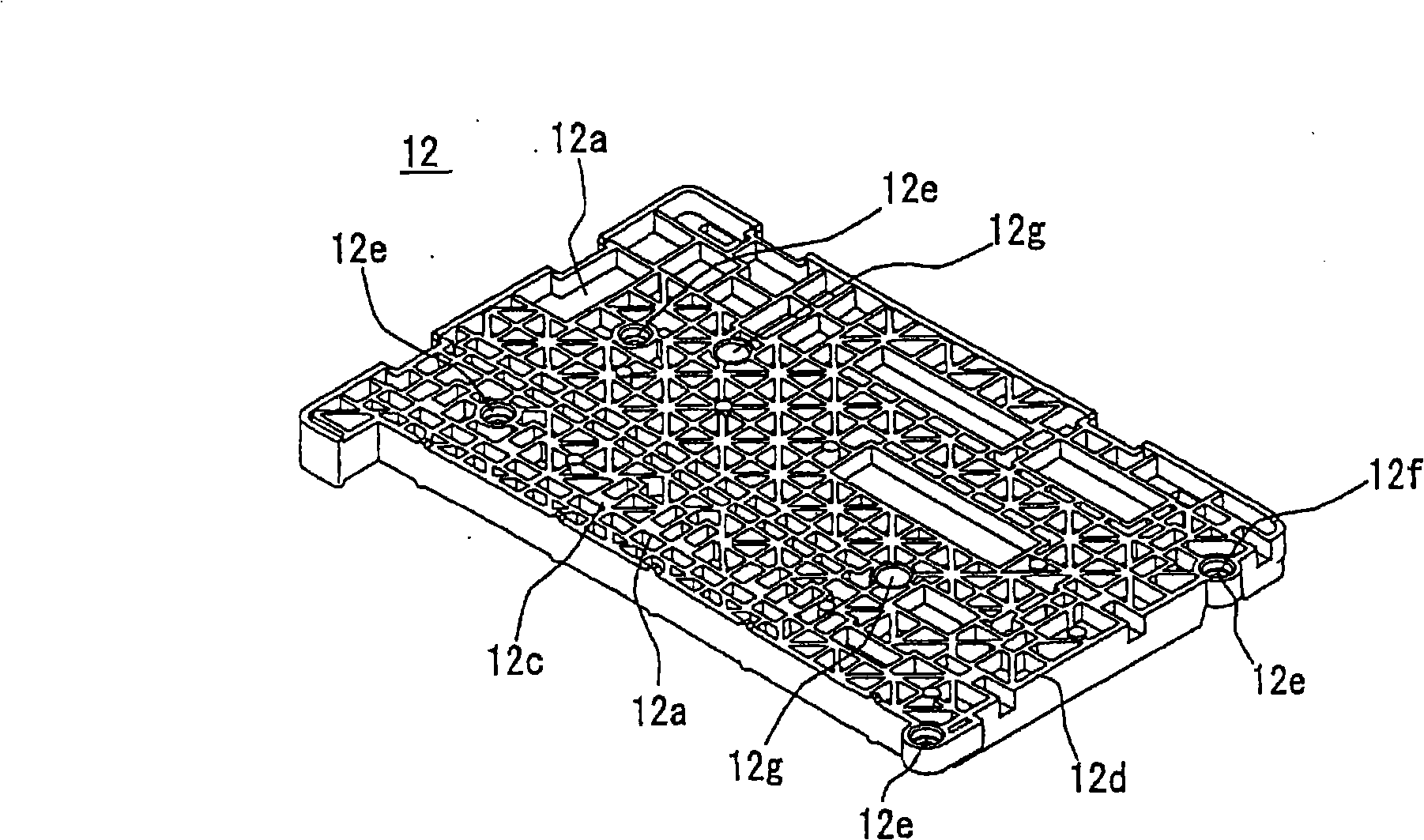

[0035] Now refer to the attached Figures 1 to 5 , an embodiment of the electrical junction box according to the present invention will be described below.

[0036] The electric junction box is installed in the motorcycle such that the electric junction box is inclined in the motorcycle.

[0037] as attached figure 1 As shown in and 2, the electrical junction box may include a cover assembly having an upper cover 10 and a lower cover 11. The bus bar lamination unit 18 and the printed circuit board unit 15 can be housed in the cover assembly so that they are disposed from the upper cover 10 to the lower cover 11, and the bus bars 16 and insulating plates 17 are alternately laminated in the bus bar lamination unit , the printed circuit board unit includes a first printed circuit board 13 , a spacer 12 and a second printed circuit board 14 .

[0038] The shorter-sized fixing rod 10x may be integrally formed with the inner surface of the top wall 10a of the upper cover 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com