End cap board and motor rotor containing the same

A technology of motor rotor and end cover plate, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of easy magnetic permeability of screws, increase in manufacturing cost and time, influence magnetic field, etc., and achieve stable embedding The effect of grouping magnetic bodies, reducing assembly costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

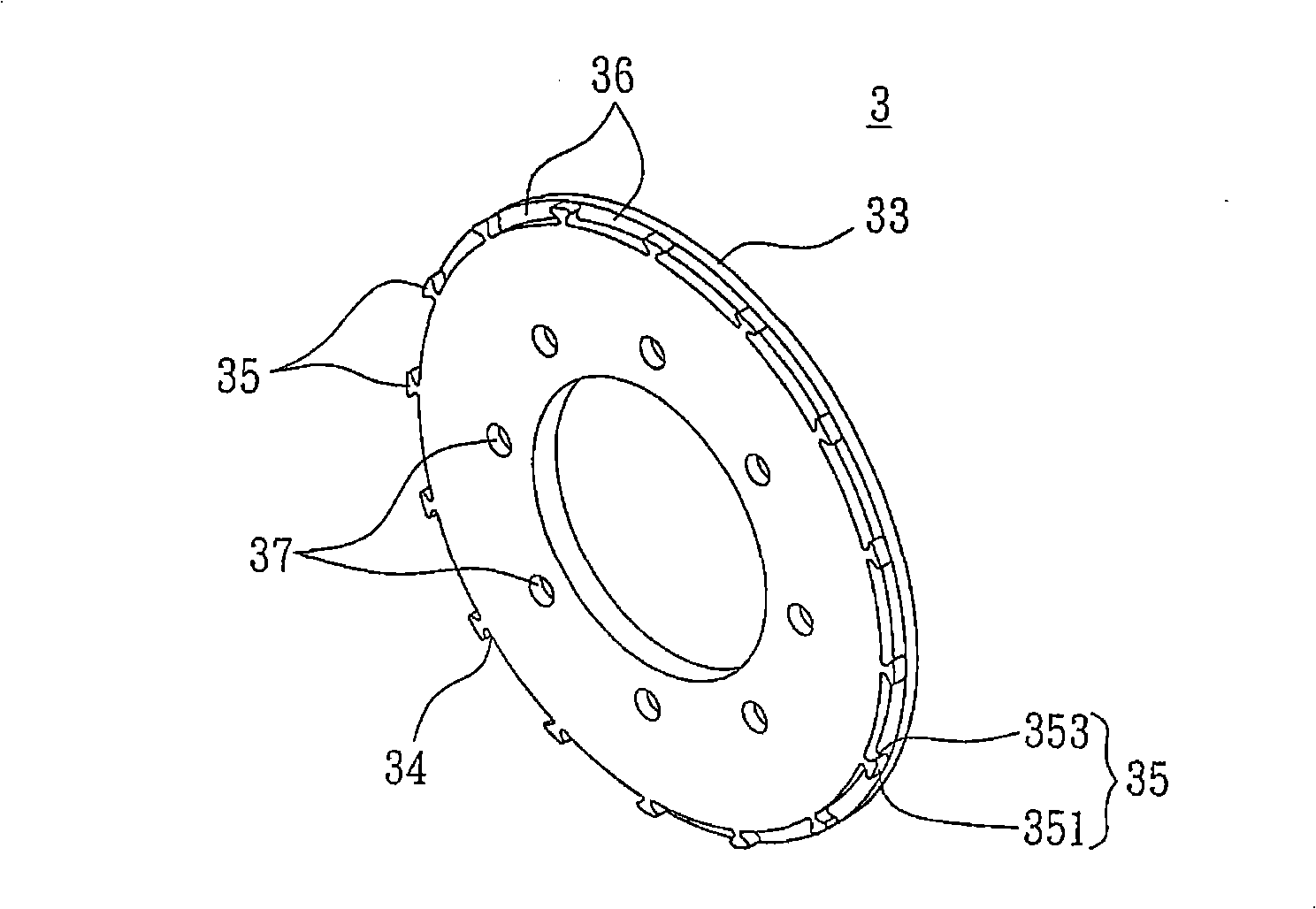

[0063] Figure 3A and Figure 3B It is a structural schematic diagram and a partial cross-sectional view respectively showing an embodiment of the end cover plate 3 of the present invention. The end cover plate 3 is supplied for being combined with the end surface of the rotating shaft of the motor rotor, and is used for fixing and surrounding the multiple walls arranged around the rotating shaft. A magnetic body (to be stated later), such as Figure 3A and Figure 3B As shown, the end cover plate 3 has a first surface 31 facing the end surface of the rotating shaft and an opposite second surface 32. The first surface 31 has a plurality of radially inward recesses from the edge and corresponding to each of the magnetic bodies. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com