Monodisperse aerosol generator

An aerosol generator and aerosol technology, applied in the direction of dissolution, microcapsule preparation, chemical instruments and methods, etc., can solve problems such as difficulties, poor monodispersity, complex structure, etc., and meet the requirements of simplified configuration and low pressure bearing requirements , easy-to-obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

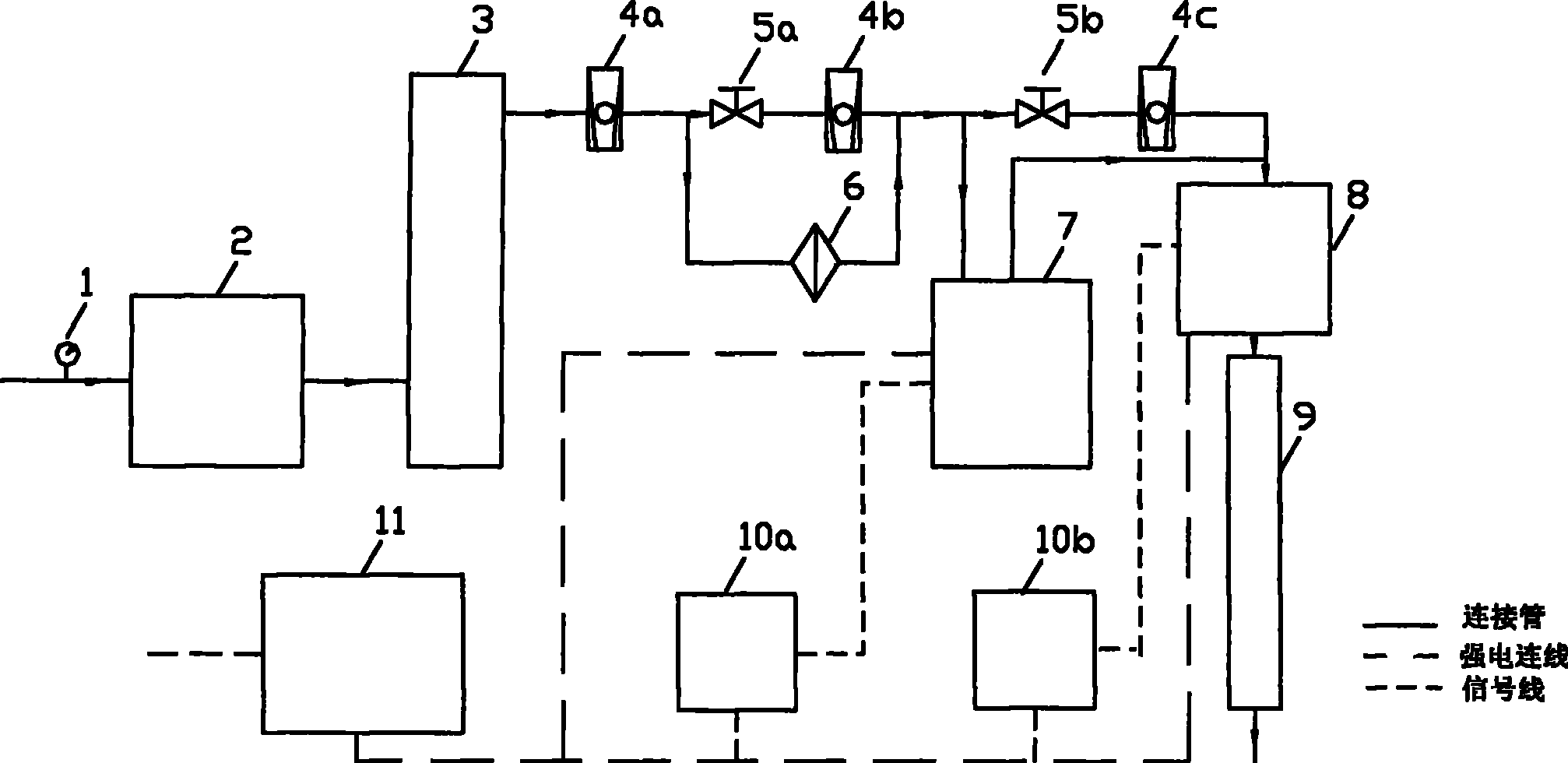

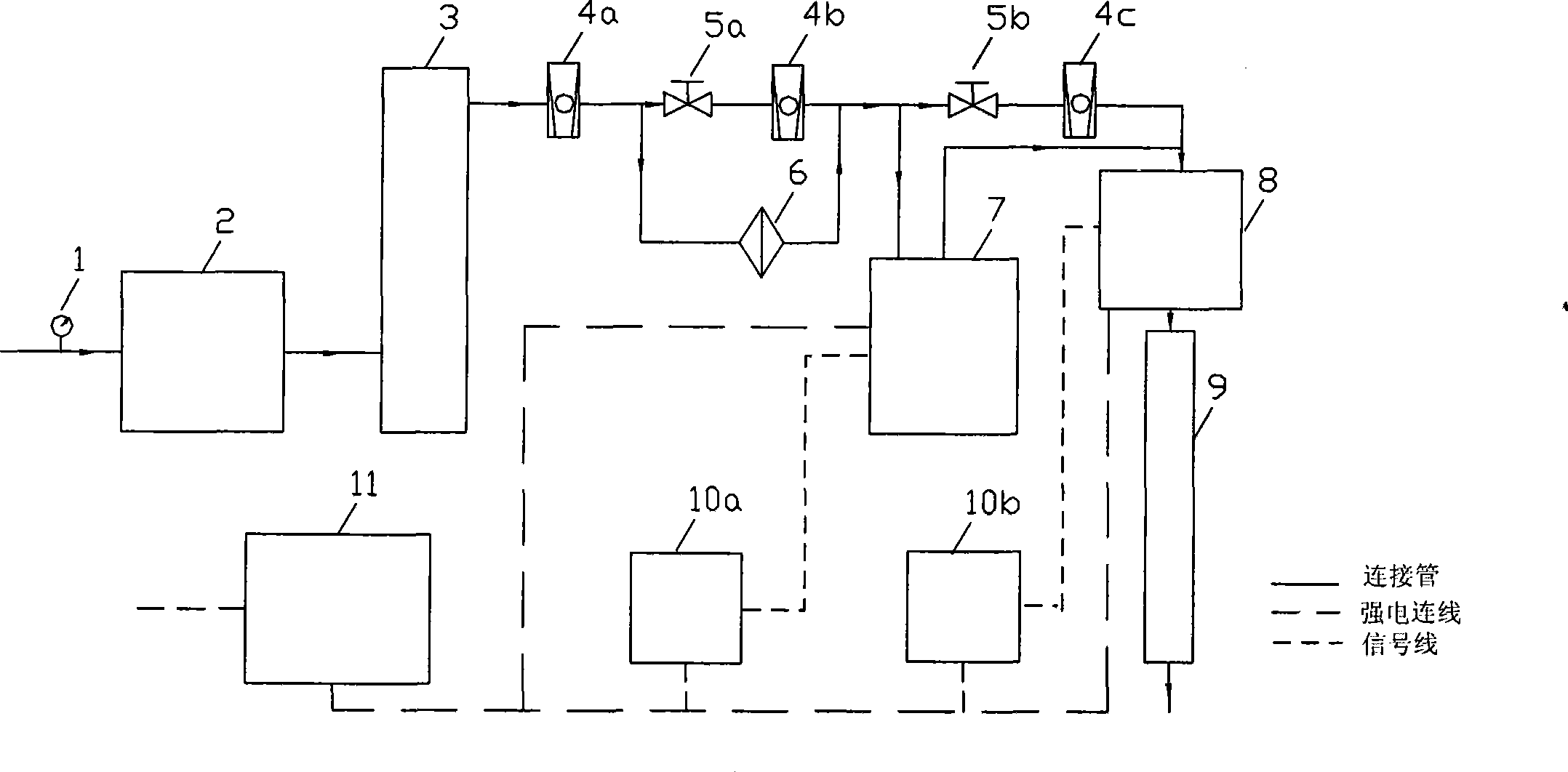

[0025] As shown in Fig. 1, a monodisperse aerosol generator of the present invention is developed using the principle of "cloud formation", that is, steam wraps on condensation nuclei to form aerosol particles. It consists of four parts: 1) Part where condensation nuclei occur; 2) Part where steam occurs; 3) Part where aerosol is formed; 4) Device control and regulation part. Along the aerosol formation process, the condensation nucleus source part, the steam generation part and the aerosol formation part are sequentially connected in series; the device control and regulation part is connected with the steam generation part and the aerosol formation part. The following describes the composition and functions of the four parts.

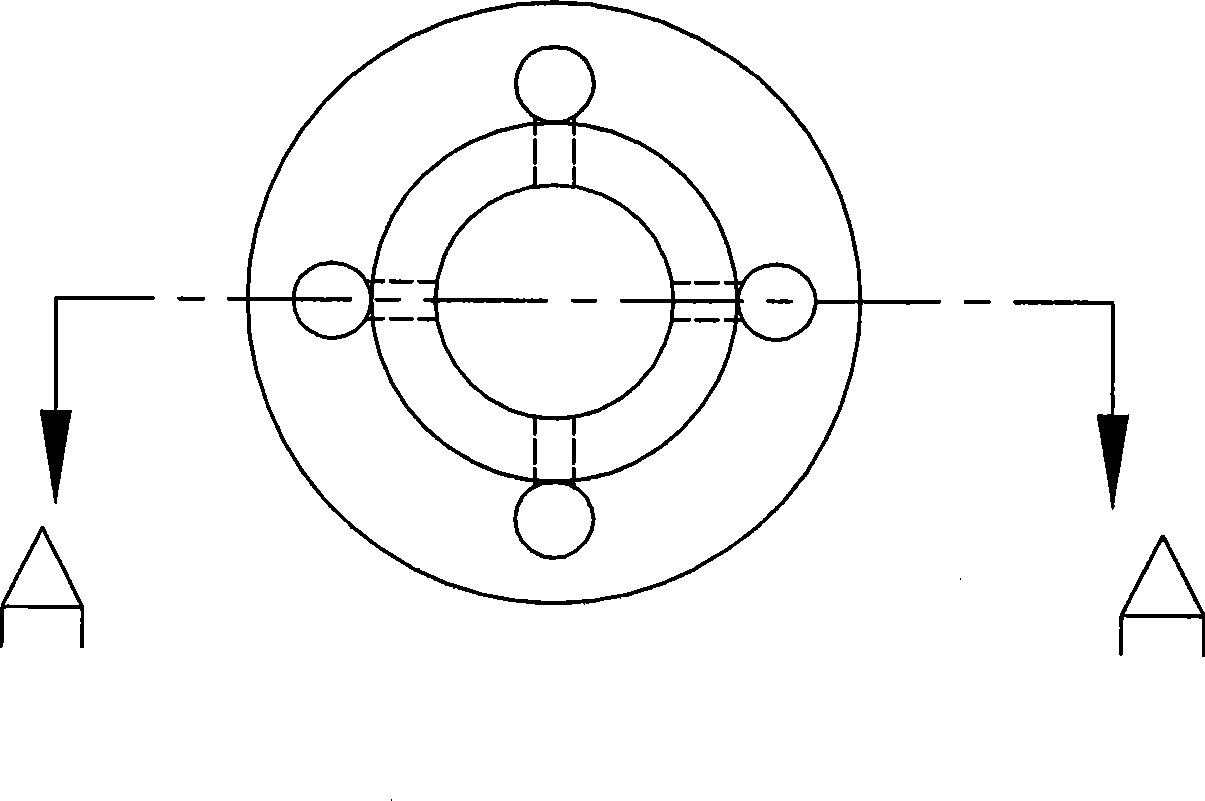

[0026] 1) Condensation source part: This part is composed of pressure gauge 1, sprayer 2 and drying pipe 3 in series. Pressure gauge 1 is used to measure the spray pressure. Sprayer 2 is mainly used to spray liquid aerosol particles. It is the key par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com