Industrialization energy-saving building house

一种房屋、建筑的技术,应用在产业化节能建筑房屋领域,能够解决施工时间长、施工效率低、周边环境影响大等问题,达到增加居住舒适度和有效使用面积、减少能源和用水的消耗、减少现场施工作业的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

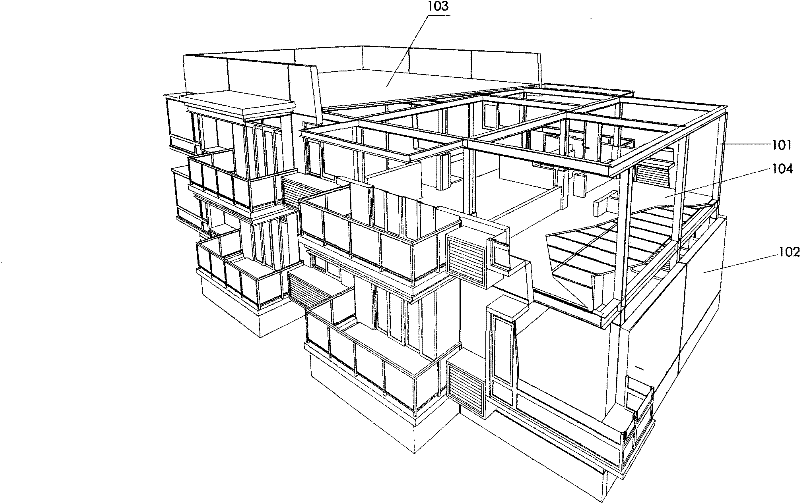

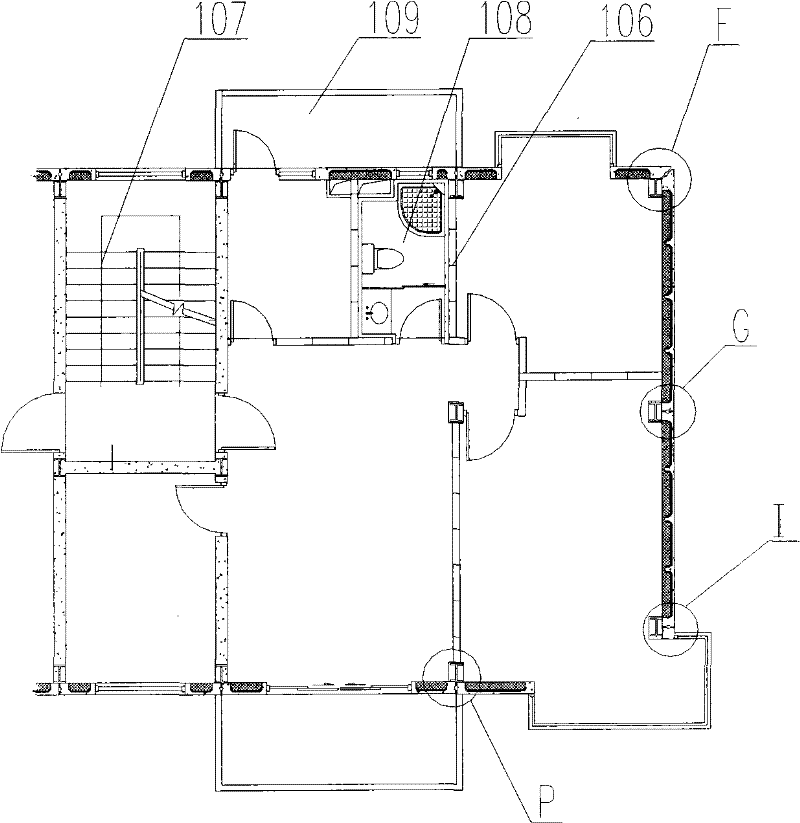

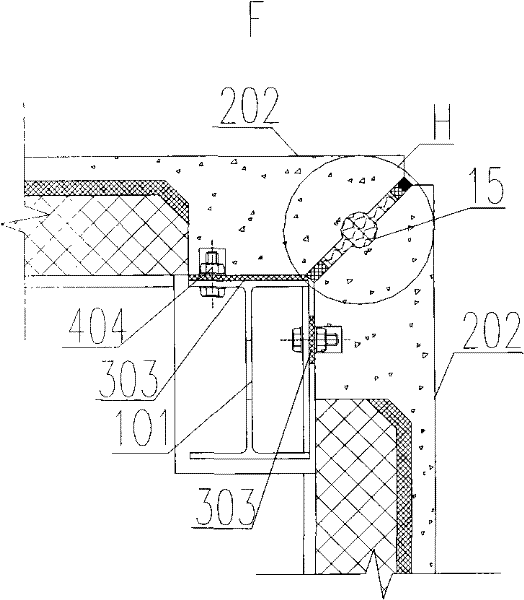

[0044] Such as Figure 1a , 1b As shown, an industrialized energy-saving building house includes a main body frame 101, an enclosure exterior wall, a roof panel 103, a floor panel 104, an indoor partition wall 106, a staircase 107, a bathroom 108, and a balcony 109. The enclosure The outer wall is assembled by integral prefabricated composite exterior wall panels. The toilet 108, balcony 109, and staircase 107 are respectively prefabricated integrated prefabricated bathroom, integrated prefabricated staircase, and integrated prefabricated balcony, which are directly hoisted to the design position for installation. The main force-receiving frame 101 is a steel structure force-receiving frame. The main force-receiving frame 101 of the steel structure includes steel beams and steel columns. The steel beams and steel columns are connected together by welding or high-strength bolts. 101 can also be the main force frame of the reinforced concrete structure. The integral prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com