Full copper inner container heat water pot

A hot water tank and liner technology, which is applied in the field of wall-mounted all-copper liner hot water tanks, can solve the problems of poor sealing performance, difficult to clean, poor material ductility, etc., and achieves strong anti-corrosion and sterilization ability, foaming and heat preservation effect. Good, simple and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

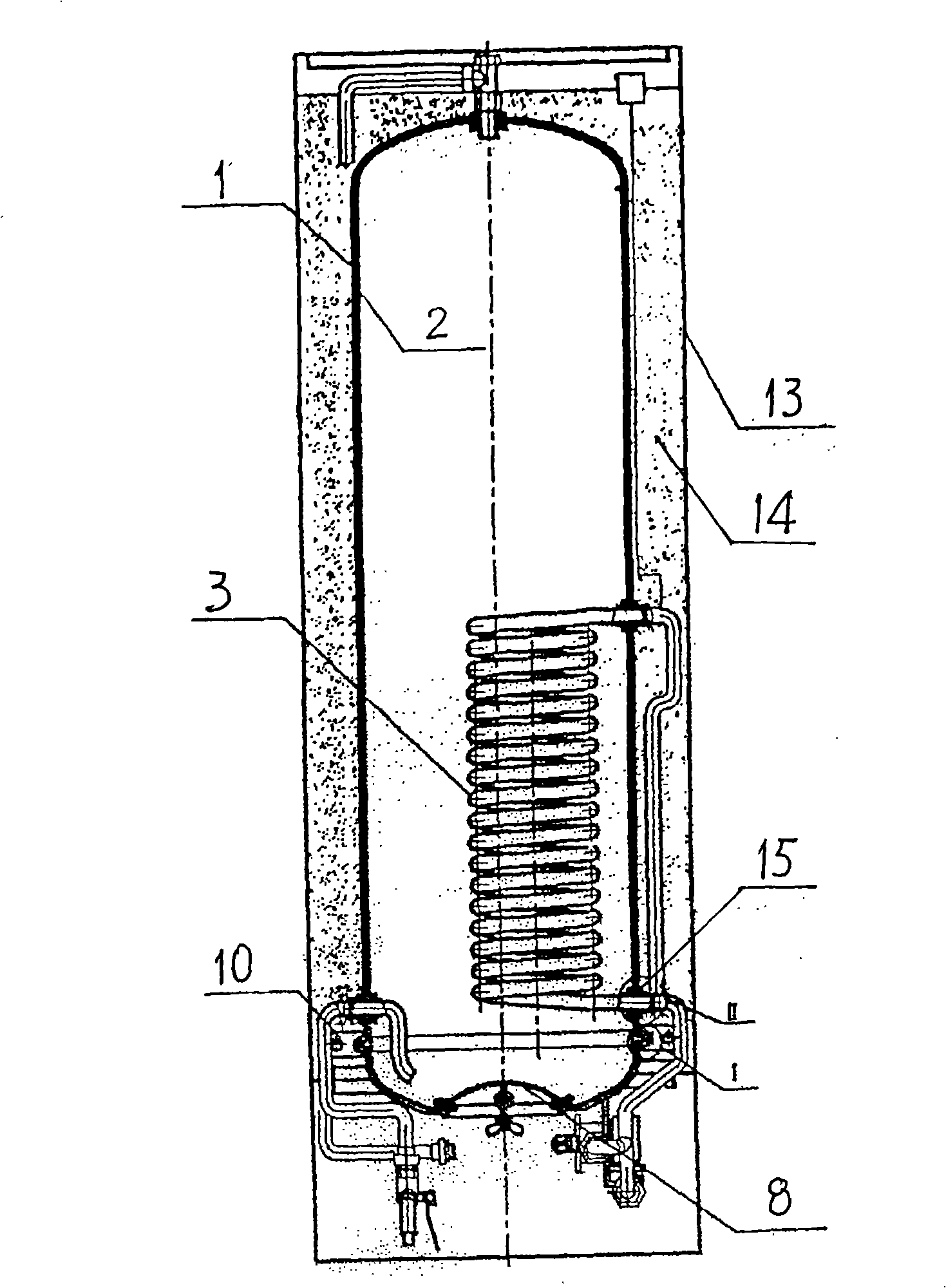

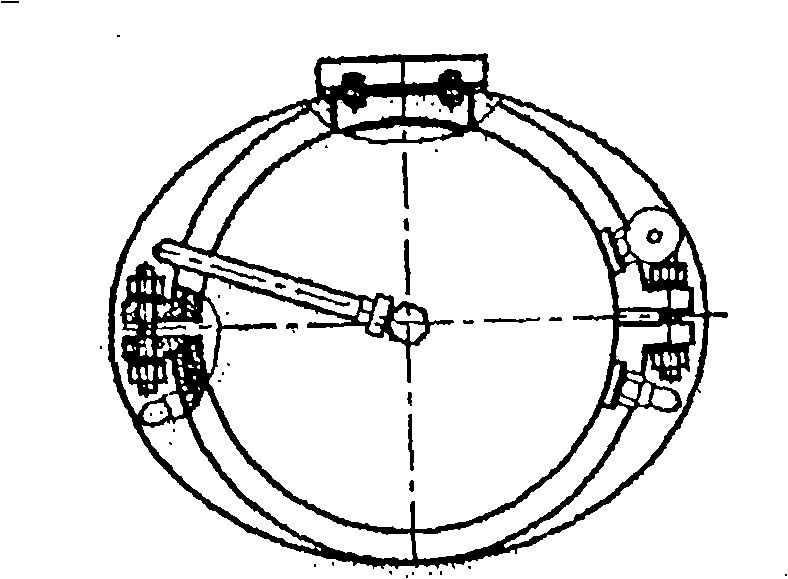

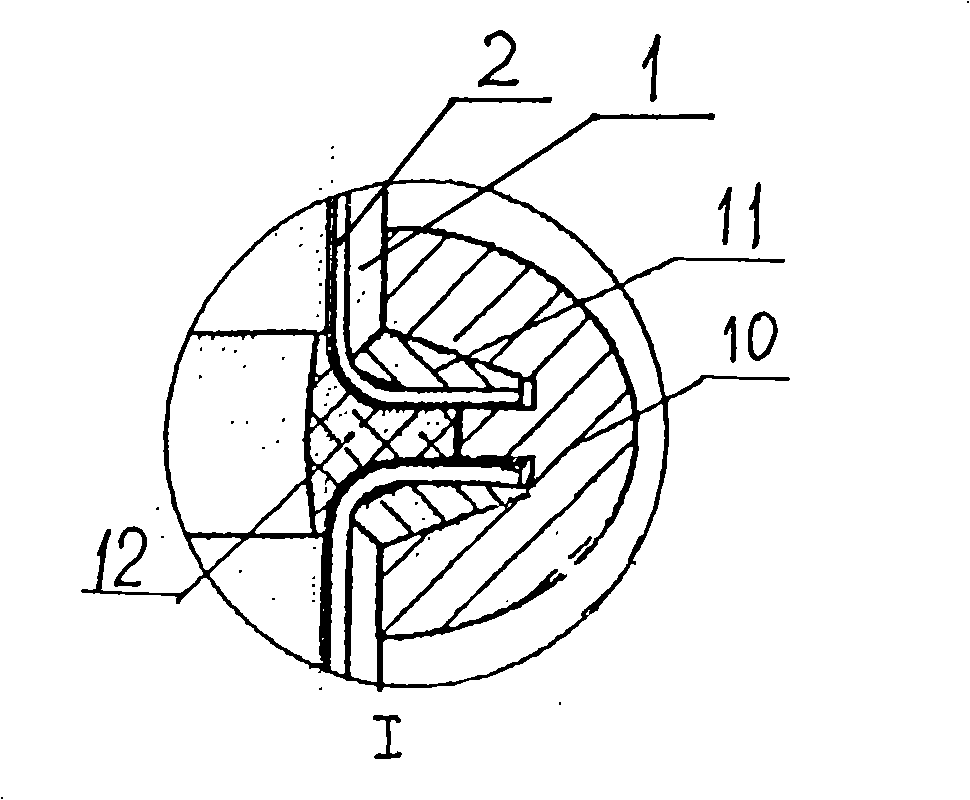

[0015] Referring to the accompanying drawings, the inner tank of the present invention adopts a copper inner tank 2, and a metal outer tank 1 is closely attached and fixed outside the copper inner tank, such as a steel outer tank, which greatly reduces the thickness of the copper inner tank and saves copper materials. The cost is reduced, and the metal outer bladder 1 increases the strength. A copper coil tube group 3 is installed in the copper liner 2, and the external connection pipe of the copper liner adopts a threaded connection and a flat sealing structure, and brazing 4 at the pipe joint, Figure 4 Among them, 5 is inside the tank, and 6 is outside the tank, see figure 1 , Figure 5 , the metal outer tank 1 and the bottom of the copper inner tank 2 have a cleaning hand hole 7 pressed from the inside to the outside, and are equipped with a hand hole cover 8 and a hand hole cover sealing ring 9, see also figure 1 , image 3 , The copper inner tank 2 and the steel outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com