Optical diffusion thin film and LCD device using the same

A liquid crystal display device and optical diffusion technology, applied in the field of optical diffusion film and liquid crystal display device, can solve the problems of limited light-gathering ability of the film, loss of the light-gathering ability of the film, low brightness of the display device, etc., and achieve good optical diffusion effect, less The effect of combining component count, high optical uniformity and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

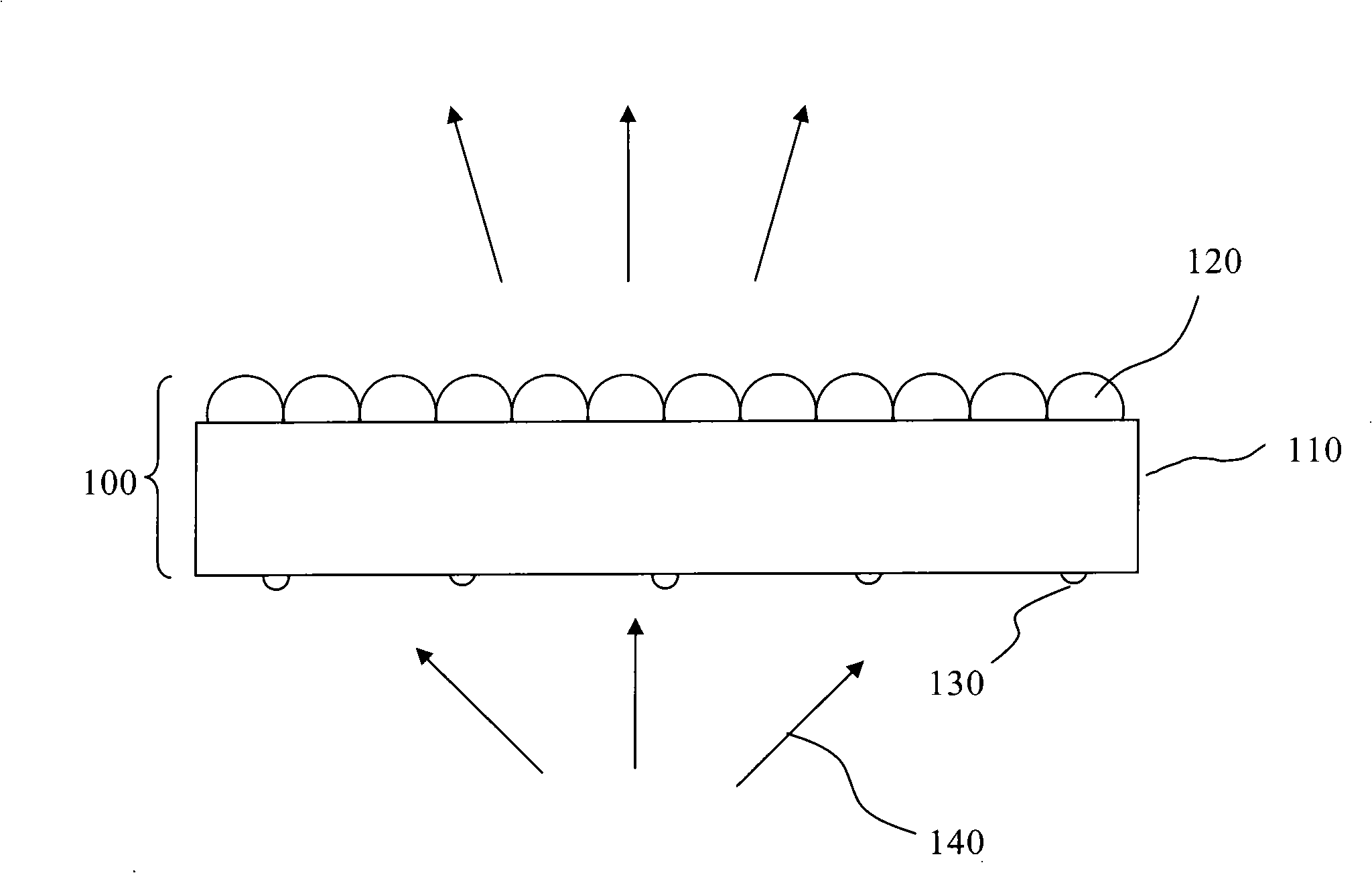

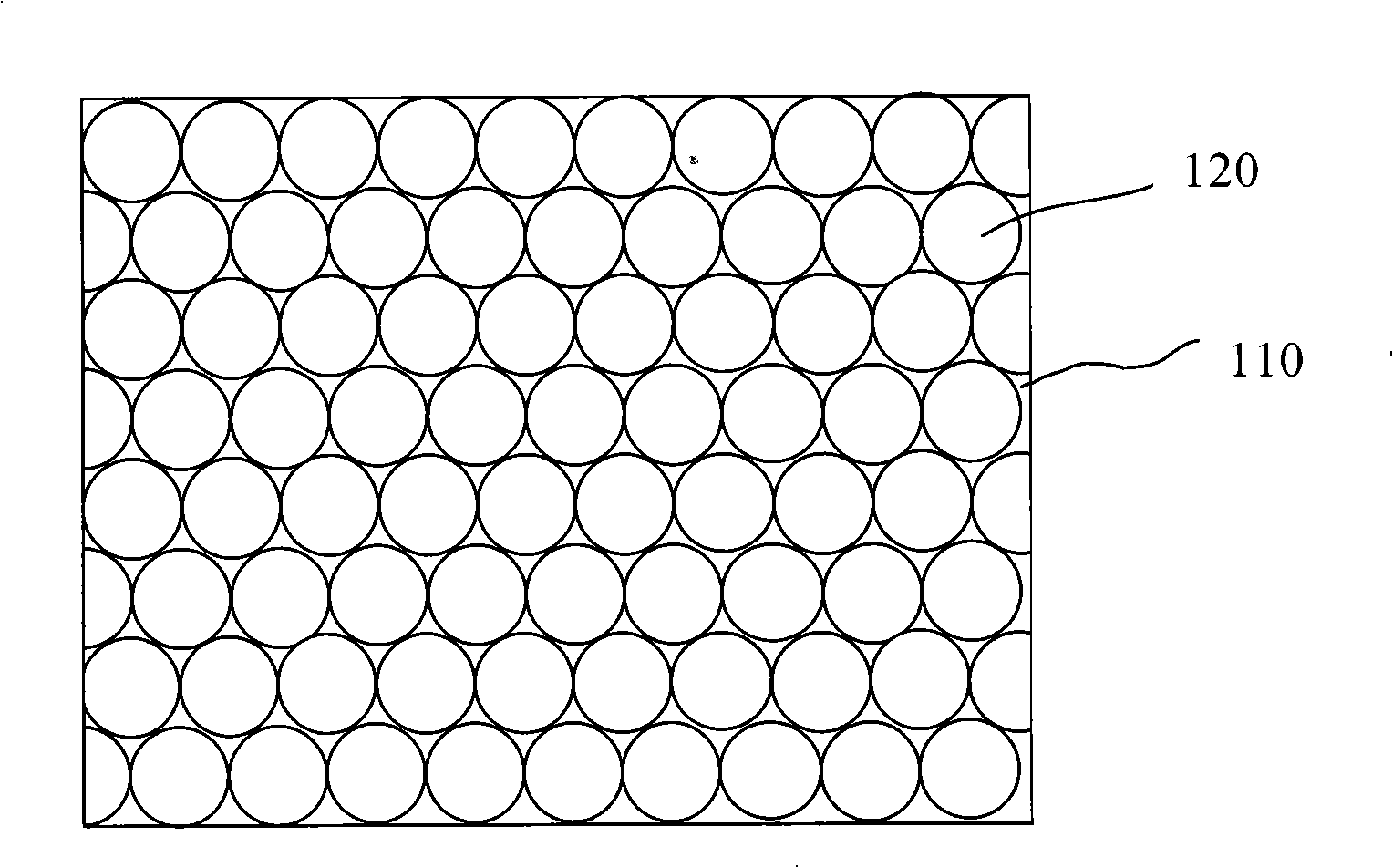

[0029] Example one, as Figure 2A , Figure 2B As shown, the optical diffusion film 100 mainly includes a transparent body 110, the material of which is a transparent polycarbonate (PC) material with a refractive index of 1.586, the protrusions on its upper surface are hemispherical protrusions 120 with a diameter of 80 microns, and the protrusions are arranged in the order of Arranged in a hexagonal shape, two adjacent hemispherical patterns 120 are closely attached to each other to achieve a maximum duty cycle. The array formed by the hemispherical protrusions 120 forms an optical micro-lens group, so that the light 140 incident from the lower surface of the film can be continuously reflected and refracted by it after entering the optical diffusion film 100 to achieve the effect of optical diffusion, and at the same time, it can make the light 140 Concentrate in the direction of propagation to the center to form a condensing effect. The protrusions on the lower surface of ...

Embodiment 2

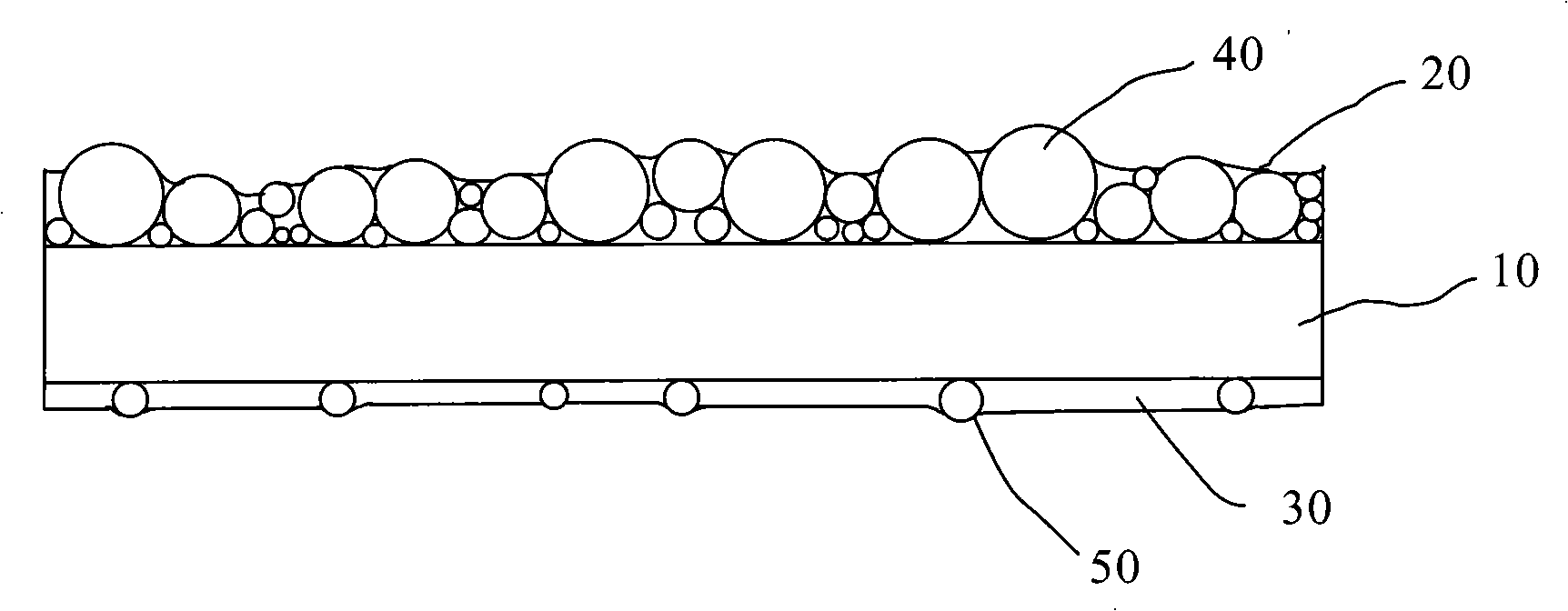

[0031] In the second embodiment, as shown in FIG. 3 , the optical diffusion film 200 also includes a transparent body 210 , the material of which is a transparent polycarbonate (PC) material with a refractive index of 1.586. The protrusions on the upper surface of the film are hemispherical protrusions 220 with diameters ranging from 15 to 80 microns, the protrusion heights ranging from 0.15 to 0.5 times the diameter, and the protrusions are arranged in a completely random arrangement. The hemispherical protrusions 220 enable the optical diffusion film 200 to have a high optical diffusion effect and a certain light-gathering ability. By adjusting the combination and density of the protrusions 220 on the upper surface of the film, the optical diffusion film 200 can control the diffusion and light-gathering capabilities of the film, and change the central viewing angle brightness and viewing angle range of the output light. Meanwhile, the protrusions on the lower surface of the ...

Embodiment 3

[0035] Example three, as Image 6 Shown is an example of application to a liquid crystal television display using two layers of the above-mentioned optical diffusion film. Among them, 610 is a lamp tube group, 620 is a high-efficiency reflective sheet, 670 is a diffusion plate in a liquid crystal TV, 640 is an optical diffusion film, and 650 is a liquid crystal display panel. In a specific implementation, a single or multiple optical diffusion films 640 can be used to meet the requirements of different brightness and viewing angle of the display.

[0036] The invention can adjust the protrusions on the upper surface of the optical diffusion film, so that the protrusions on the upper surface have different shapes at the same time, such as hemispherical protrusions, semiellipsoidal protrusions, pyramid-shaped protrusions, and conical protrusions. The arrangement of protrusions can be rectangular, hexagonal or random to form patterns; the protrusions on the lower surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com