Optical diffusion film

A technology of optical diffusion and thin film, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of increasing the luminous efficiency of the backlight module of the liquid crystal display, the brightness of the liquid crystal display device is not high, and the light-gathering ability of the film cannot be guaranteed, so as to avoid the occurrence of Spotting, maintaining optical uniformity, protective coating gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

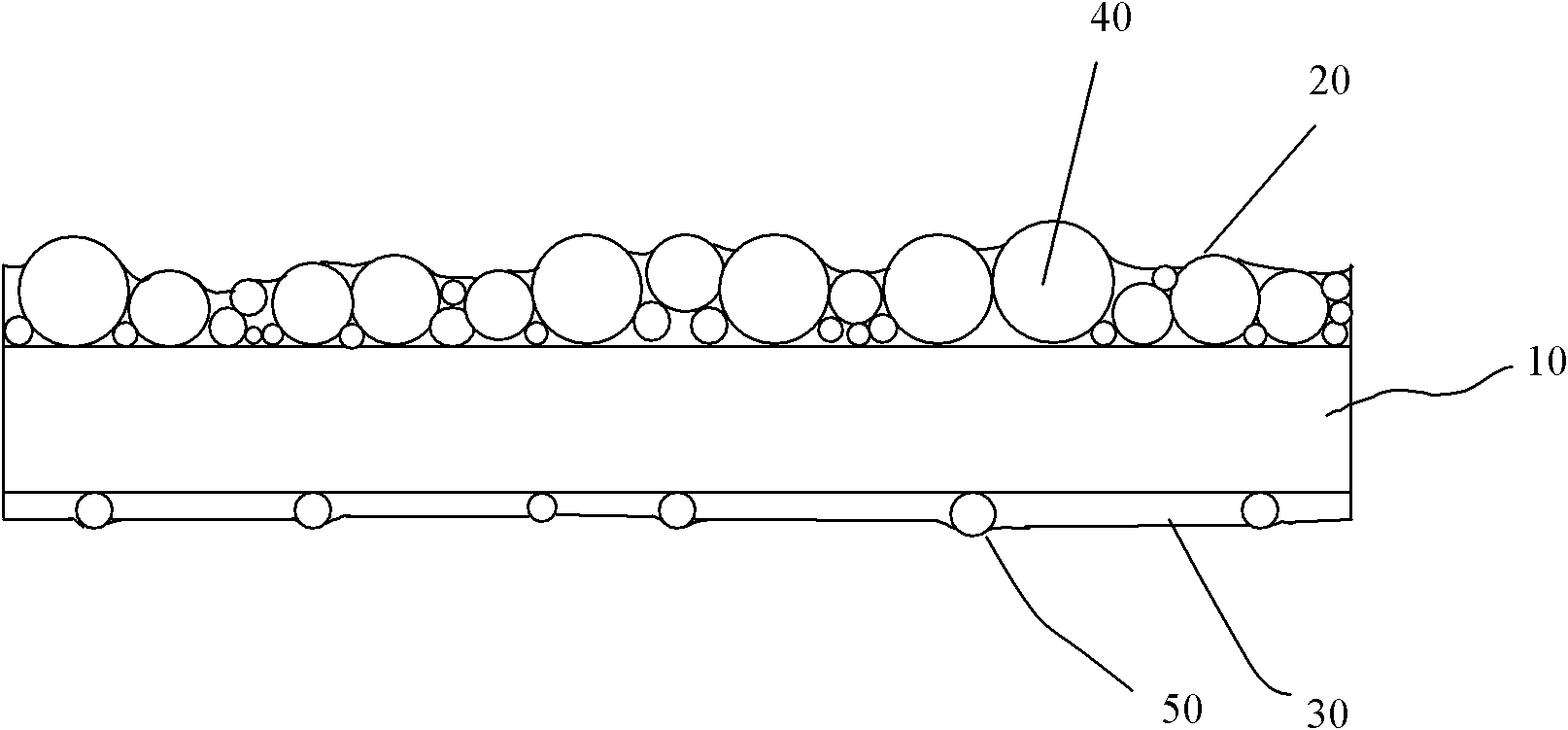

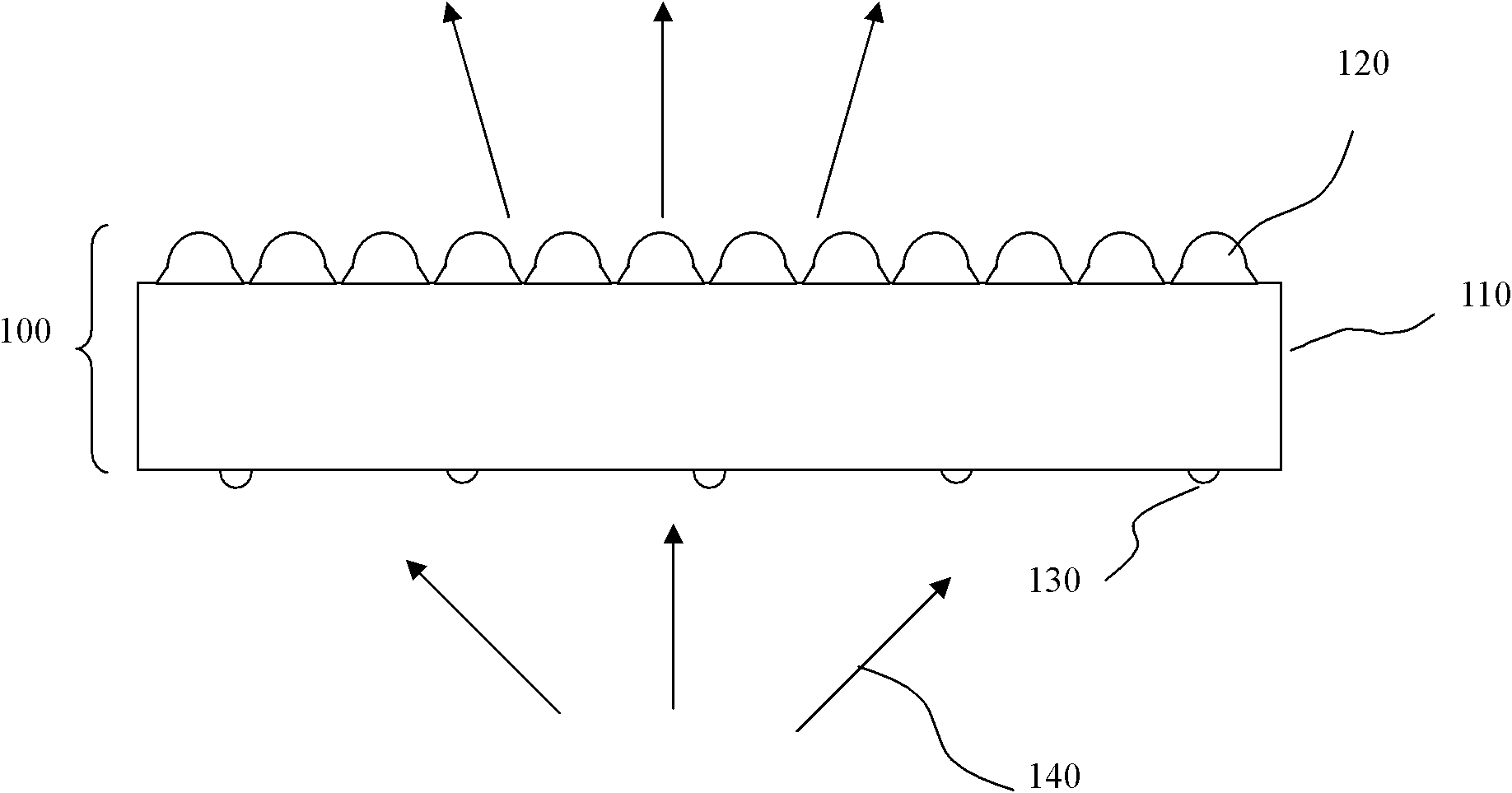

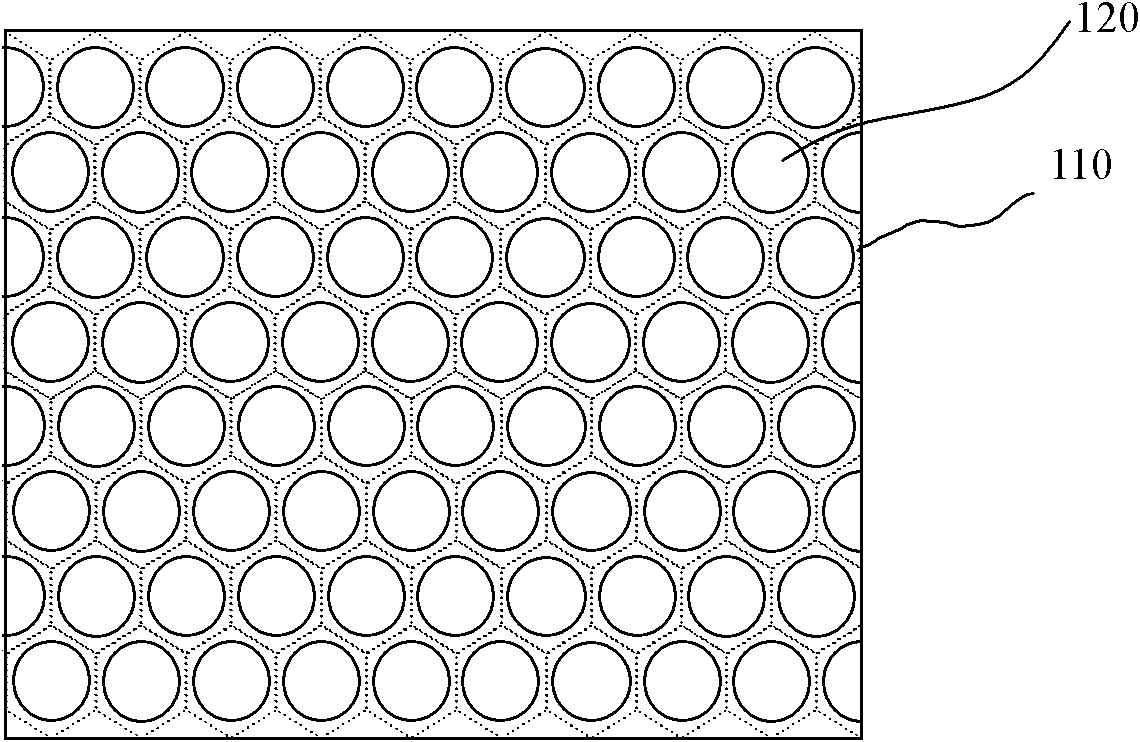

Embodiment 1

[0030] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the optical diffusion film 100 mainly includes a polymer material body 110 and a protruding structure 120, the refractive index of the polymer material body 110 is 1.58, and the main component of the polymer material body 110 and the protruding structure 120 is 94% polycarbonate PC , 5% of antistatic molecules, 0.5% of UV absorbers, 0.5% of antioxidants are made by mixing them by conventional methods. The above-mentioned engineering plastics is polycarbonate; the above-mentioned antistatic agent is alkylbenzenesulfonic acid-alkyl phosphonium salt; the above-mentioned anti-ultraviolet absorber is 2-hydroxyl-4-n-octyloxybenzophenone; the above-mentioned Antioxidant is bis 2.4-di-tert-butylphenyl pentaerythritol diphosphite. The upper surface of the optical diffusion film 100 protrudes into a protrusion structure 120 of 70 microns. The protrusion structure 120 includes a conical base 150 and a s...

Embodiment 2

[0039] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, in this embodiment, the optical diffusion film 100 mainly includes a polymer material body 110 and a protruding structure 120, the refractive index of the polymer material body 110 is 1.35, and the main components of the polymer material body 110 and the protruding structure 120 are 97% polycarbonate PC, 2% antistatic molecules, 0.5% UV absorber, 0.5% antioxidant are mixed. The above-mentioned engineering plastics is polycarbonate; the above-mentioned antistatic agent is alkylbenzenesulfonic acid-alkyl phosphonium salt; the above-mentioned anti-ultraviolet absorber is 2-hydroxyl-4-n-octyloxybenzophenone; The antioxidant is bis 2.4-di-tert-butylphenyl pentaerythritol diphosphite. Wherein, the single upper surface protruding structure 120 of the optical diffusion film 100 is composed of a conical base 150 with a regular hexagonal bottom and a spherical cap 160 structure on the conical base 150,...

Embodiment 3

[0042] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, in this embodiment, the optical diffusion film 100 mainly includes a polymer material body 110 and a protruding structure 120, the refractive index of the polymer material body 110 is 1.8, and the main components of the polymer material body 110 and the protruding structure 120 are 96% polycarbonate PC, 3.9% antistatic molecules, 0.05% UV absorber, 0.05% antioxidant. The above-mentioned engineering plastics is polycarbonate; the above-mentioned antistatic agent is alkylbenzenesulfonic acid-alkyl phosphonium salt; the above-mentioned anti-ultraviolet absorber is 2-hydroxyl-4-n-octyloxybenzophenone; The antioxidant is bis 2.4-di-tert-butylphenyl pentaerythritol diphosphite. The single upper surface protruding structure 120 of the optical diffusion film 100 is composed of a conical base 150 with a regular hexagonal bottom and a spherical cap 160 structure on the conical base 150, the overall hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com