Gas-tight module and exhaust method therefor

An exhaust method and airtight technology, applied in the direction of electrical components, gaseous chemical plating, coating, etc., can solve the problems of short circuit of semiconductor equipment, long time, reducing the productivity of semiconductor equipment, etc., and achieve the effect of preventing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0057] First, a substrate processing system including the airtight module according to the embodiment of the present invention will be described.

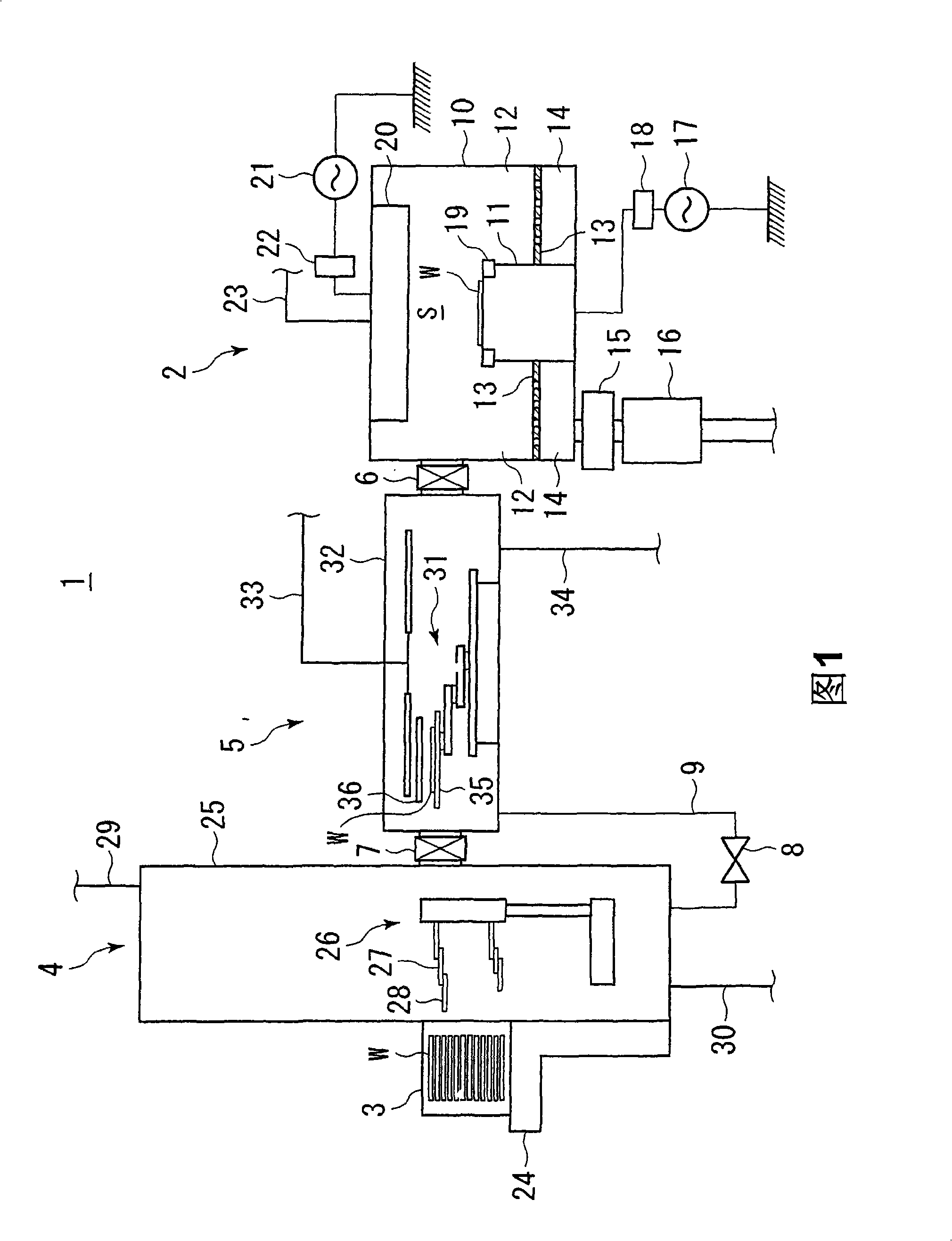

[0058] FIG. 1 is a cross-sectional view schematically showing the configuration of a substrate processing system including an airtight module according to an embodiment of the present invention.

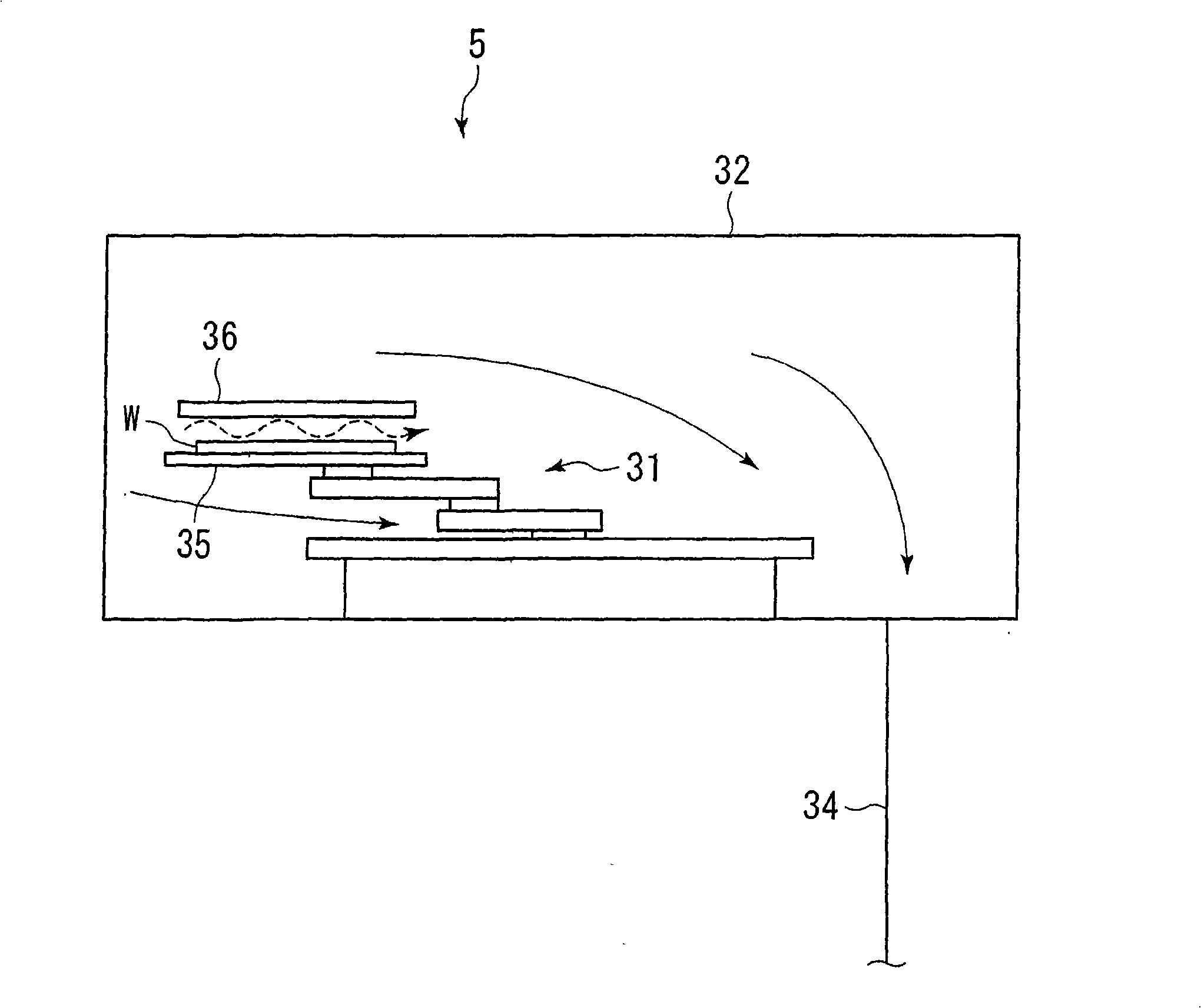

[0059] In FIG. 1 , a substrate processing system 1 includes a processing module 2 that individually performs various plasma processing, such as film formation processing, diffusion processing, and etching processing, on a semiconductor wafer W (hereinafter simply referred to as "wafer W") as a substrate. bulk processing; a loader module 4 that takes out wafers W from a wafer cassette 3 containing a predetermined number of wafers W; and a load lock module 5 (airtight module) that is arranged between the loader module 4 and the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com