Manifold for vacuum evaporation apparatus

A vapor deposition and manifold technology, which is applied to the field of manifolds for vacuum vapor deposition devices, can solve the problems of unstable film thickness distribution of vapor deposition materials, reduced conductivity of ejection channels, and difficulty in approaching nozzle openings. The vapor deposition distance is shortened, the uniformity is not deteriorated, and the vapor deposition rate is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

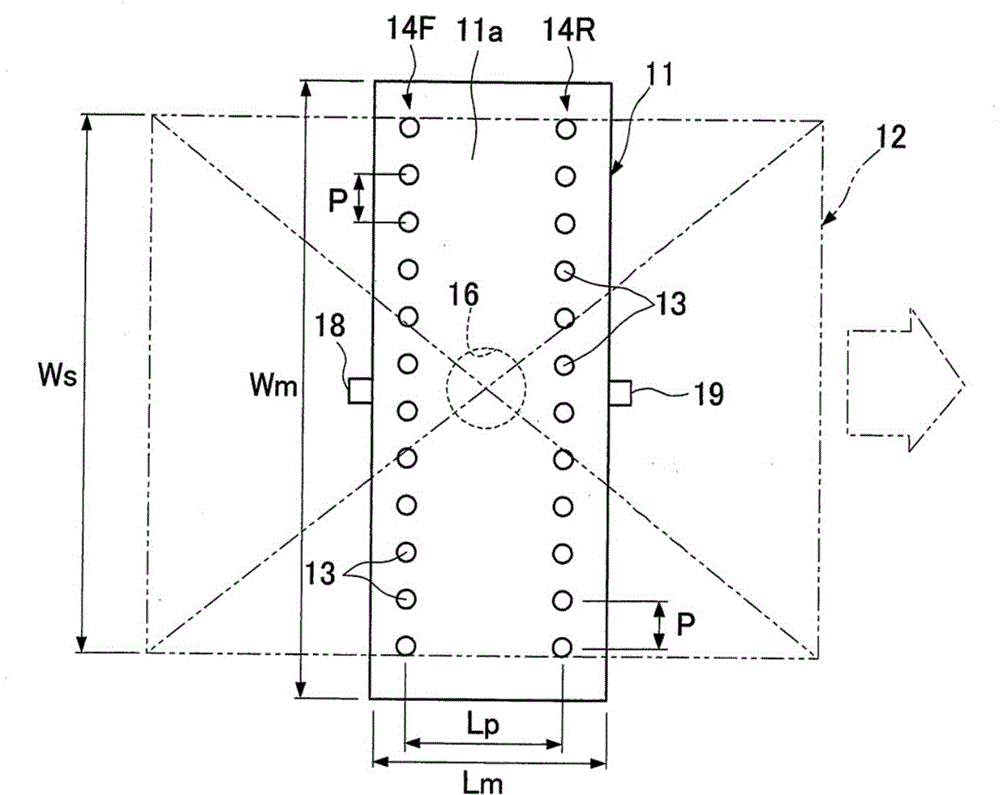

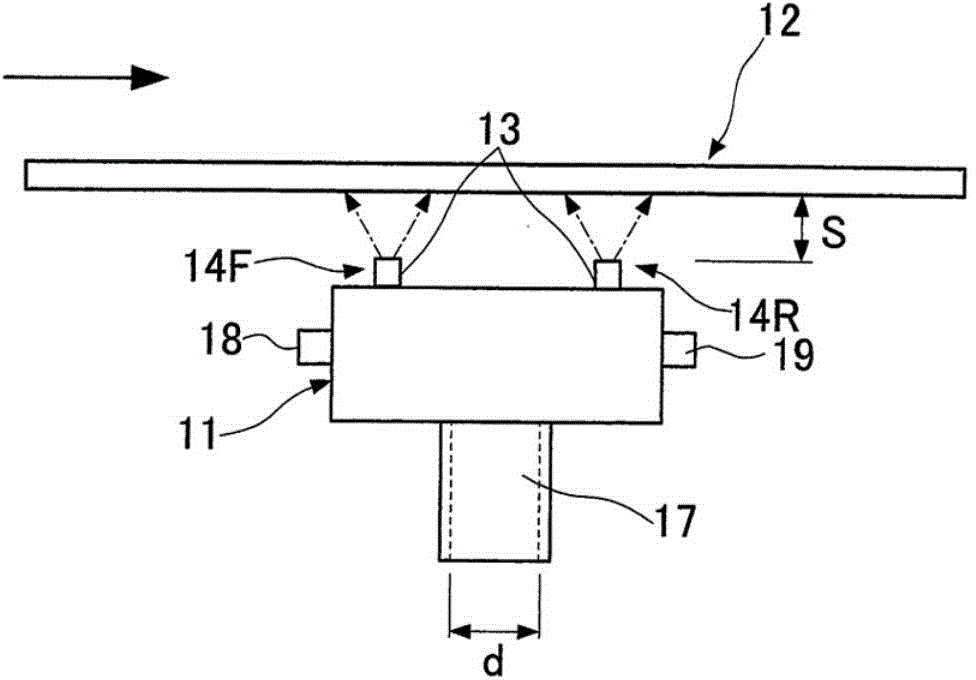

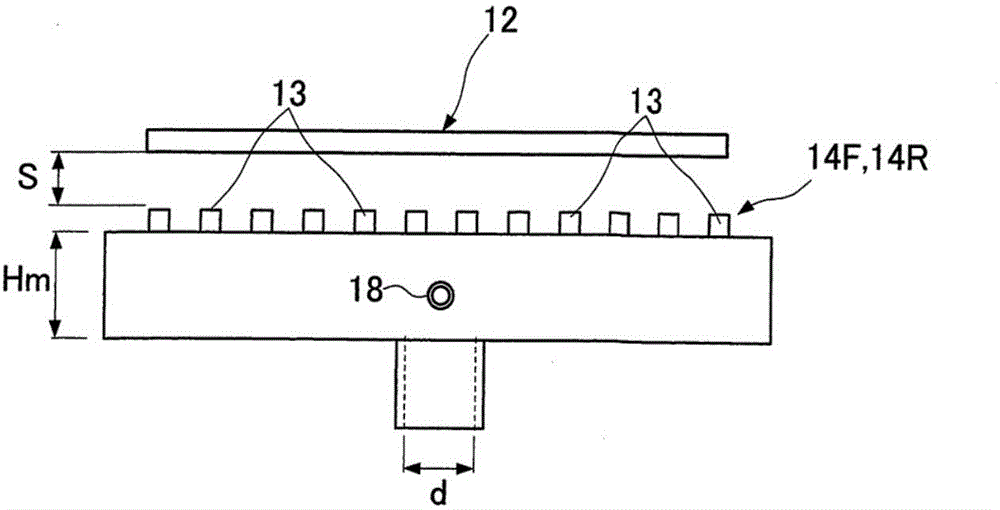

[0029] Next, Embodiment 1 of a manifold for an in-line vapor deposition system vacuum vapor deposition apparatus according to the present invention will be described based on FIGS. 1 to 4 .

[0030] Figure 1, figure 2 As shown, in a vacuum evaporation chamber maintained in a vacuum state, the manifold 11 is arranged facing the surface to be evaporated of a substrate (substrate to be evaporated) 12 moving at a constant speed. On the opposing surface 11a of the manifold 11, nozzle rows 14F, 14R are respectively provided in the front and rear of the moving direction of the substrate 12, and the plurality of ejection nozzles 13 of the nozzle rows 14F, 14R are arranged in a predetermined nozzle pattern along the width direction. The pitch P is prominently set. Here, if figure 2 As shown, the nozzle pitch P refers to the distance between the nozzle openings 15 and the nozzle openings 15 of the adjacent discharge nozzles 13 in the respective nozzle rows 14F, 14R.

[0031] The di...

Embodiment 2

[0054] Figure 8 , FIG. 9 shows Example 2 of a manifold for a vacuum vapor deposition apparatus. In this second embodiment, the same components as those in the first embodiment are given the same reference numerals, and descriptions thereof are omitted.

[0055] On the opposing surface 11a of the single manifold 11 facing the substrate 12s, nozzle rows 14F, 14R are respectively provided in front and rear of the moving direction of the substrate 12s, and the nozzle rows 14F, 14R are arranged at a predetermined nozzle pitch P A plurality of discharge nozzles 13 having nozzle openings 15 are protrudingly provided. Among the ejection nozzles 13 of the above-mentioned front and rear nozzle rows 14F, 14R, the ejection nozzles 13 of the rear nozzle row 14R are arranged at a position offset of 1 / 2P relative to the ejection nozzles 13 of the front nozzle row 14F. in the staggered position.

[0056] The structure of the discharge nozzle 13 is the same as that of the first embodiment....

Embodiment 3

[0062] Figure 10 Example 3 of a manifold for a vacuum vapor deposition apparatus is shown. Components that are the same as those in Embodiments 1 and 2 described above are assigned the same reference numerals, and explanations thereof are omitted.

[0063] Front and rear nozzle rows 14F, 14R are arranged on the substrate facing surface 11a of the manifold 11, and the nozzle rows 14F, 14R are divided into front and rear two rows 14Ff, 14Fr, 14Rf, 14Rr, respectively. The discharge nozzles 13 of the front rows 14Ff, 14Rf are shifted by 1 / 2P in the width direction of the substrate 12 from the discharge nozzles 13 of the rear rows 14Fr, 14Rr, and arranged at staggered positions.

[0064]According to the above-mentioned embodiment 3, the same effect as that of the embodiments 1 and 2 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com