Apparatus for manufacturing alloy and rare earth element alloy

A technology for producing alloys and rare earth elements, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as the difficulty of eliminating α-Fe, and achieve excellent antimagnetic force, improve antimagnetic force, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] A preferred embodiment of the apparatus for producing alloys of the present invention will be explained below with reference to the accompanying drawings. However, it should be recognized that the drawings are only used to describe the configuration of the equipment, and the sizes, widths, proportions, etc. of the various devices shown do not always reflect the size and width of the various devices of the actual equipment used to produce alloys , ratio, etc.

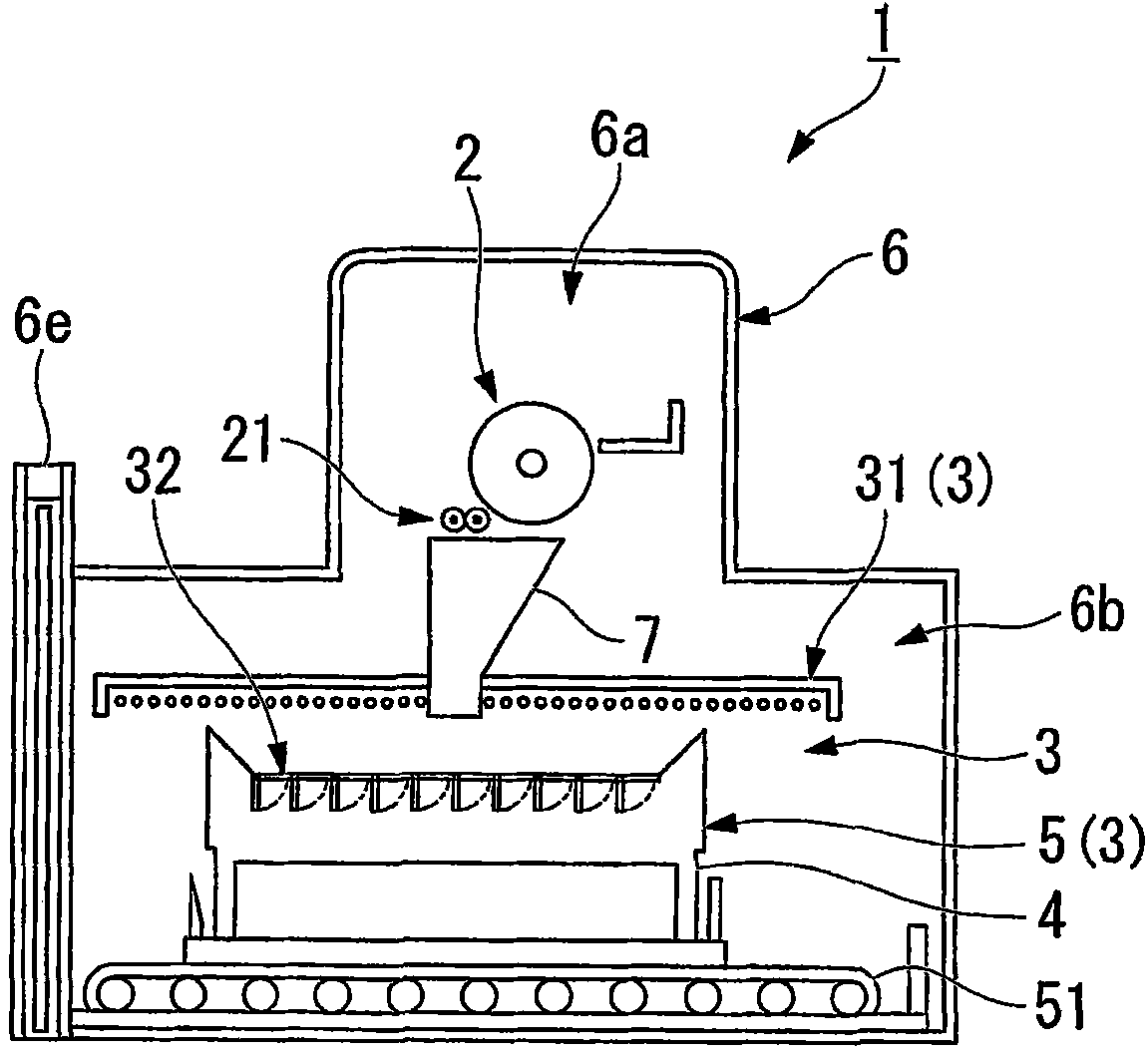

[0067] figure 1 is a front view showing one example of an apparatus for producing an alloy in the present invention.

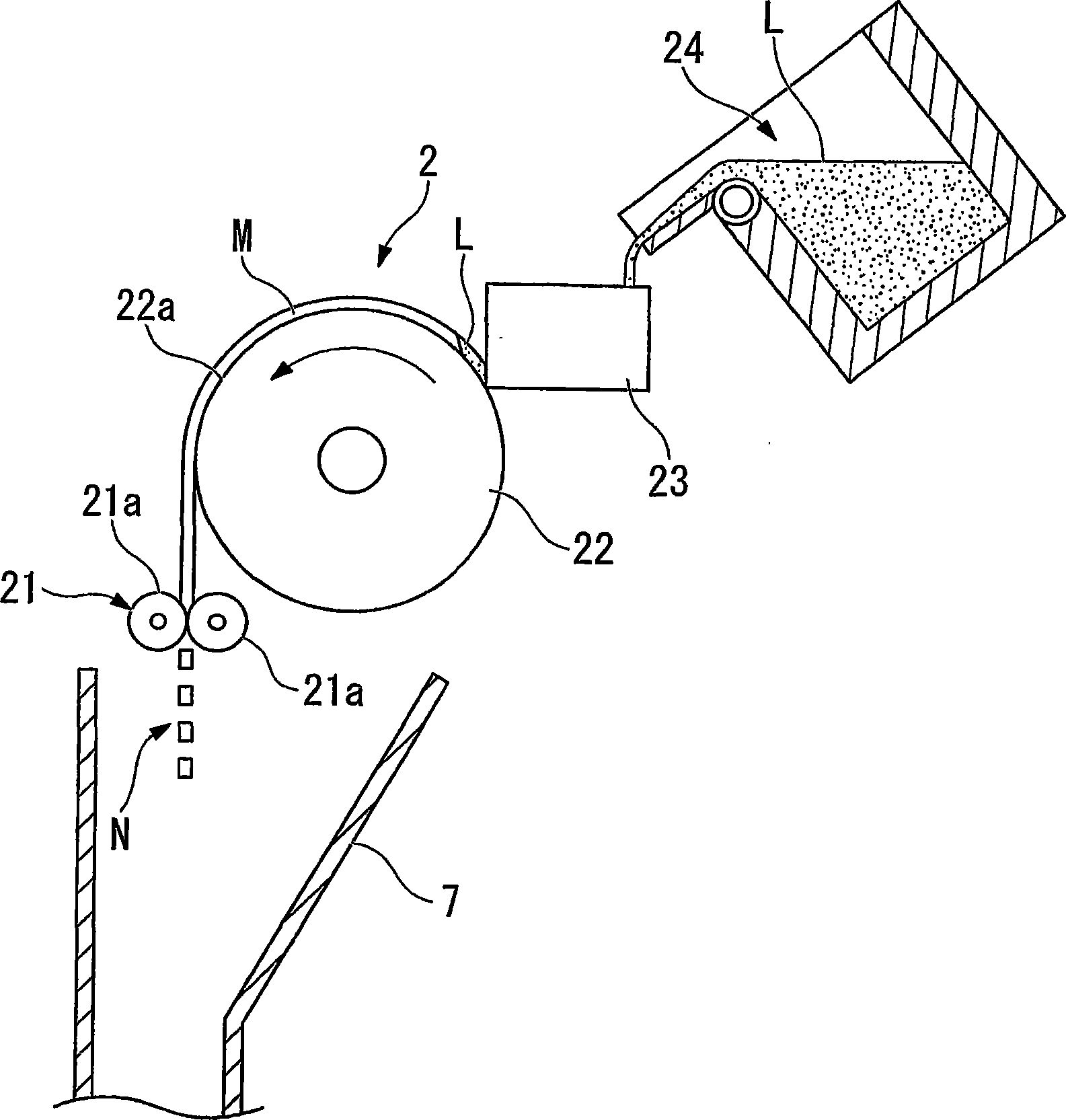

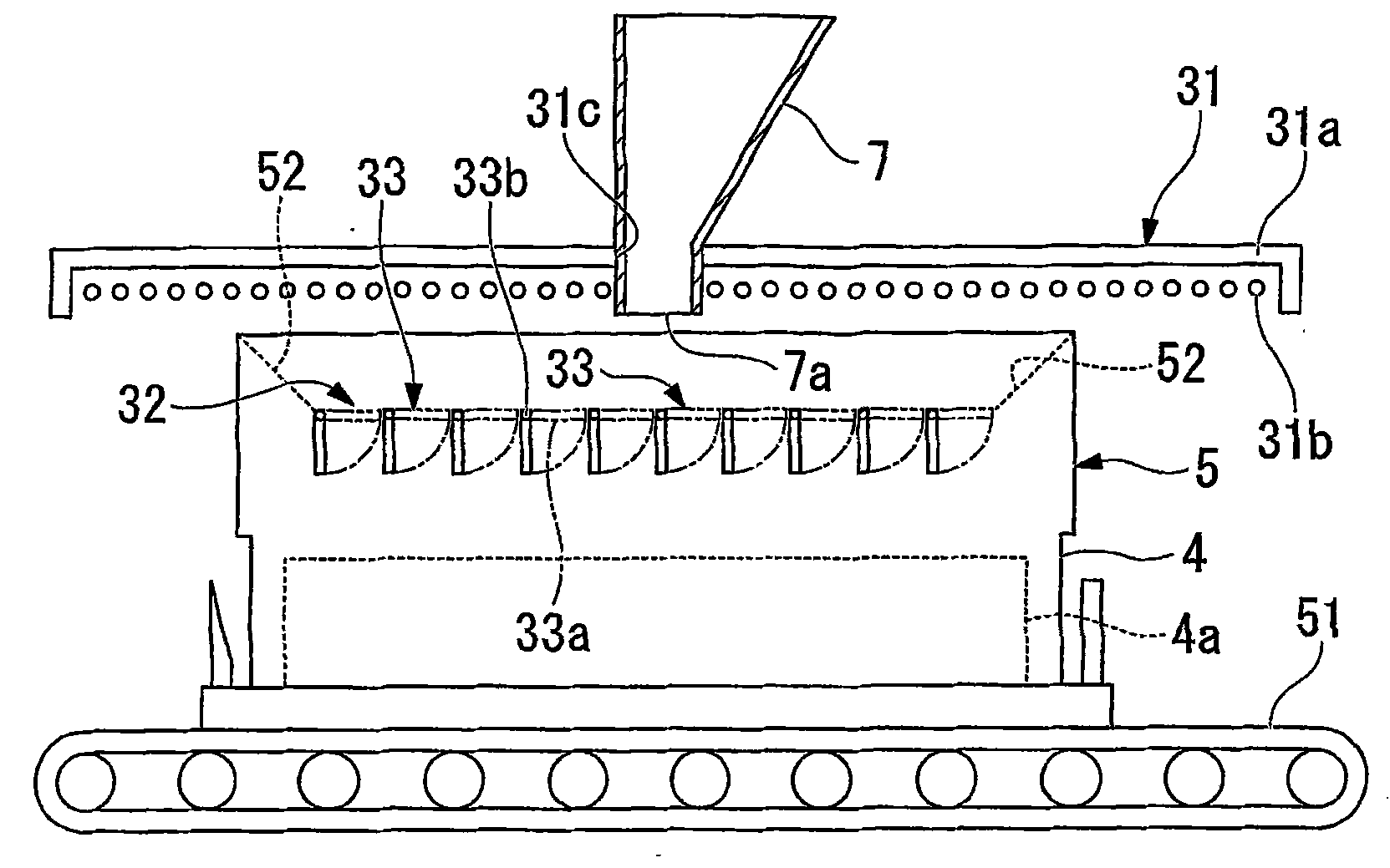

[0068] figure 1 The plant 1 for producing alloys shown in (hereinafter referred to as “production plant 1 ”) is generally equipped with a casting device 2 , a crushing device 21 , and a heating device 3 . The heating device 3 includes a heater 31 and a container 5 . The container 5 includes a storage container 4 and an opening-closing stage group 32 provided on the storage container 4 . In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com