Assembling structure of crankshaft and rotor

An assembly structure and crankshaft technology, applied in the field of compressors, can solve problems affecting motor performance, increasing equipment cost, structural changes, etc., to achieve the effects of saving assembly processes, improving fixing strength, and avoiding degaussing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

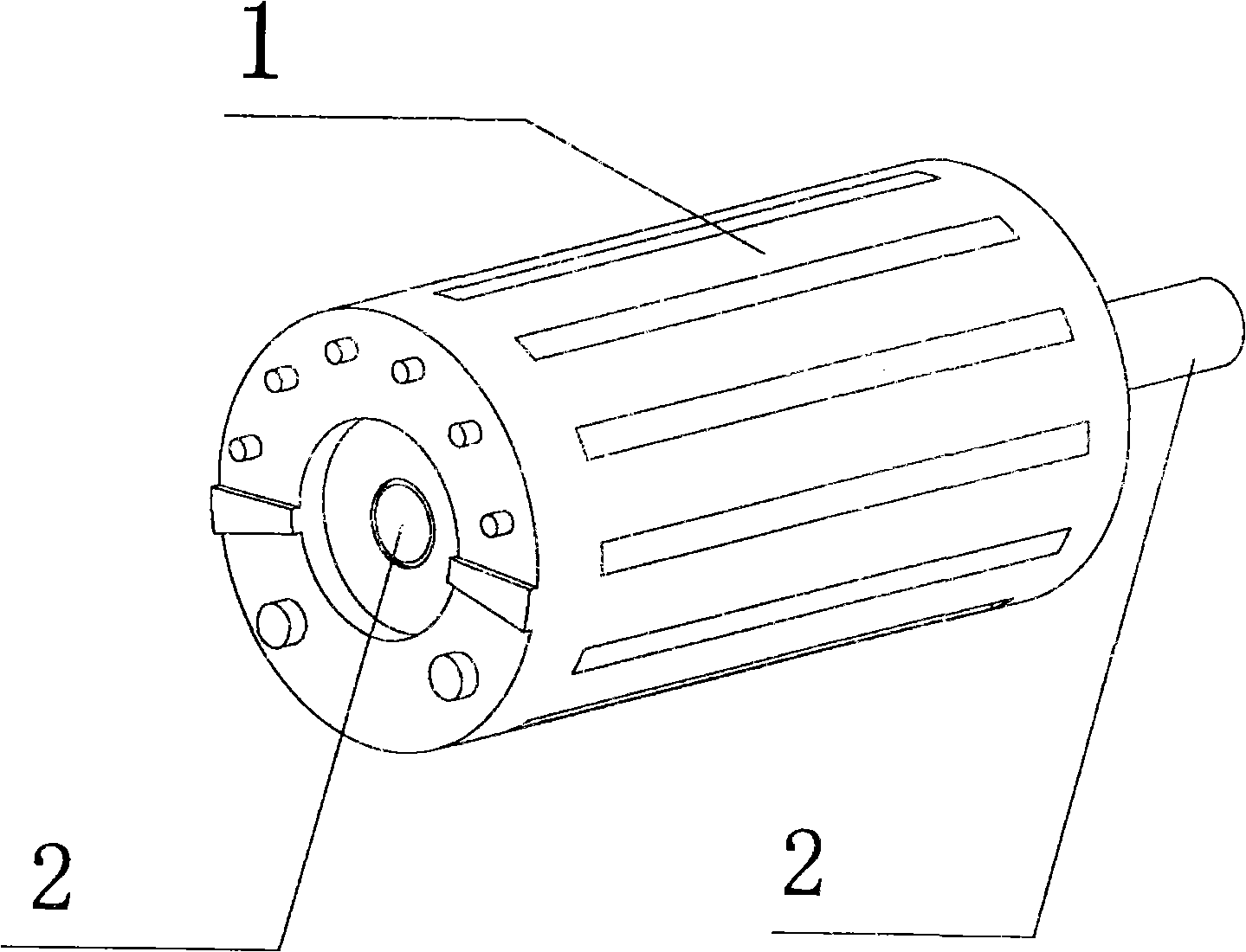

[0018] Referring to shown in Fig. 2, the assembly structure of crankshaft and rotor of the present invention, it comprises crankshaft, rotor, and the long axis portion of crankshaft is fixed in the shaft hole of rotor; There is more than one concave clamping position, and the outer surface of the long axis of the crankshaft 2 is provided with a corresponding convex structure corresponding to the clamping position, and the crankshaft and the rotor are assembled by means of the convex structure and the concave clamping position. One.

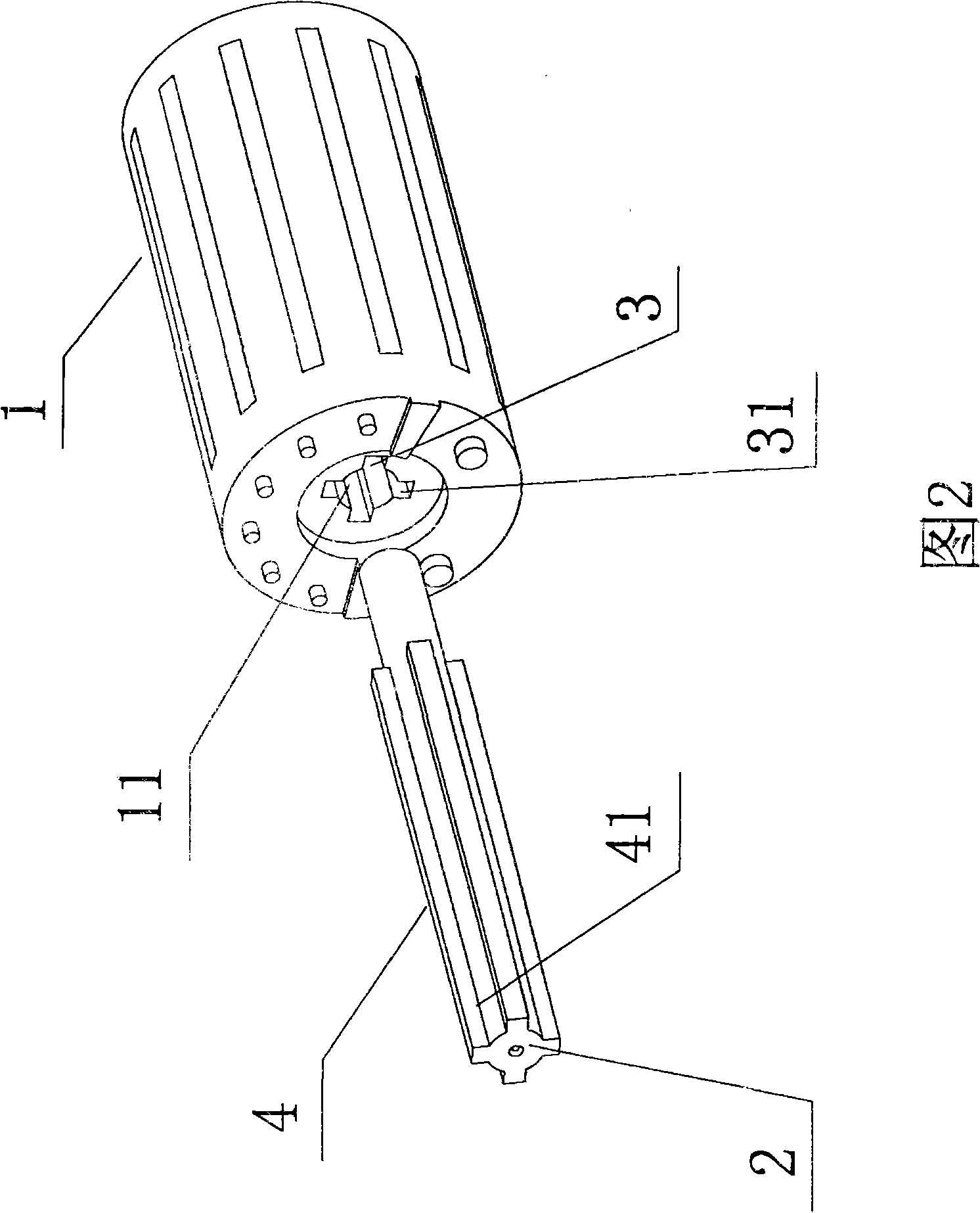

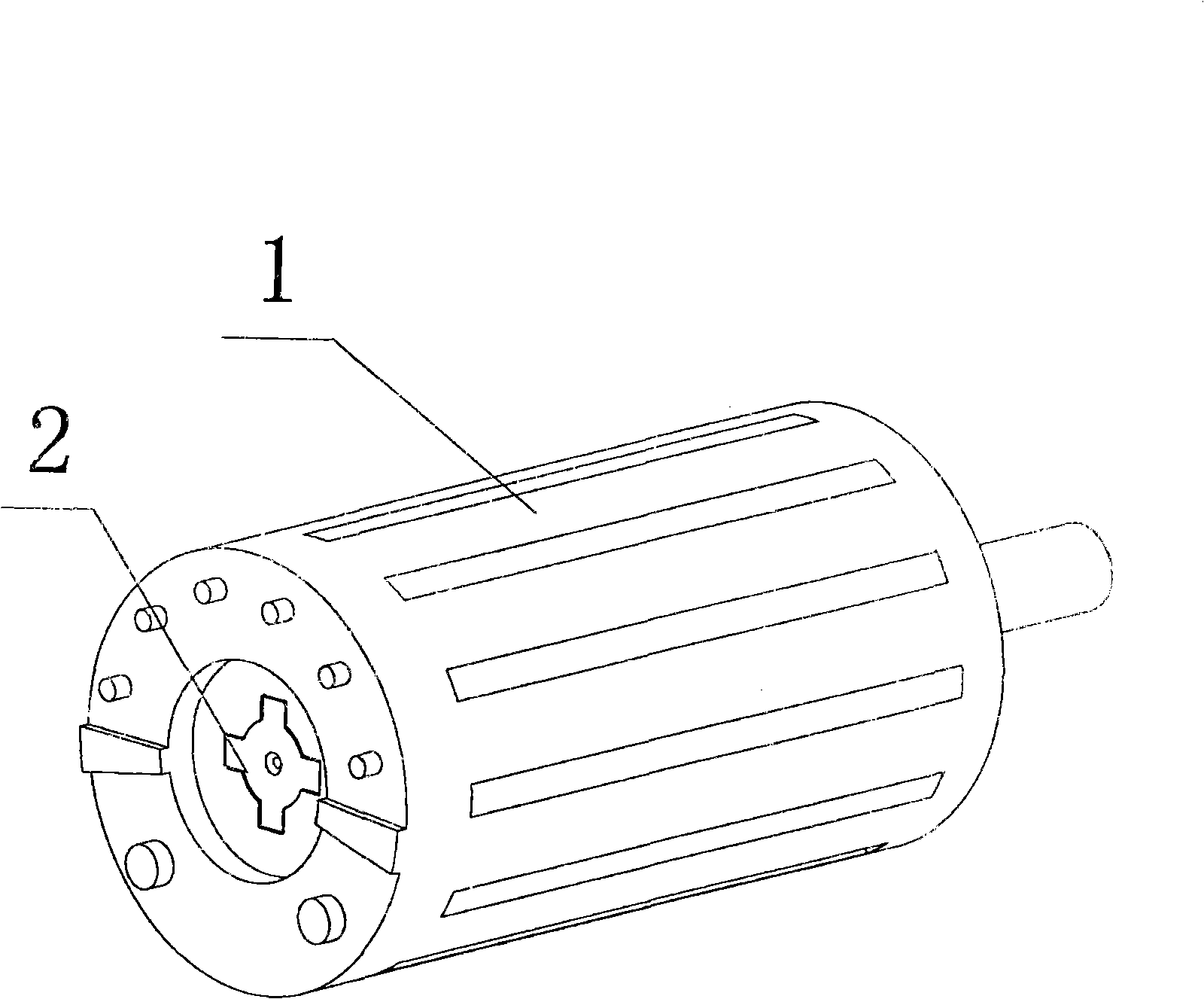

[0019] refer to image 3 As shown, the assembly structure of the crankshaft and the rotor of the present invention, wherein the inner concave stop provided on the inner edge of the shaft hole 11 of the rotor 1 is an inward concave groove 3, and the outer surface of the long axis of the crankshaft 2 is provided with a The corresponding protruding structure of the card position is the boss 4 .

[0020] refer to image 3 As shown in the assembly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com