Axial push-pull fatigue test cramp for metal thin wall pipe sample

A fatigue test, sample axial technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of large plate fixture size, complex processing technology, laborious and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

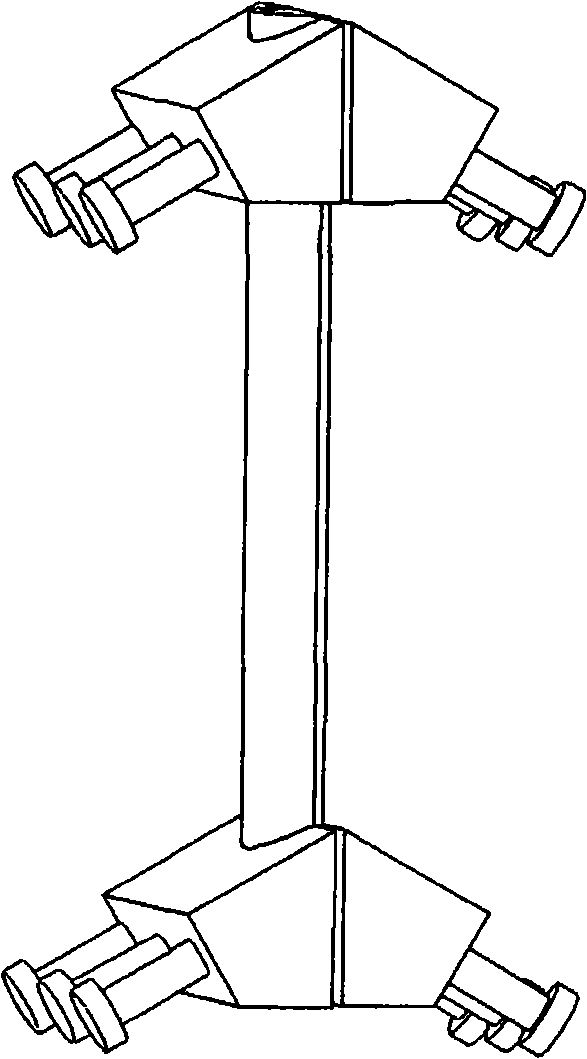

[0012] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

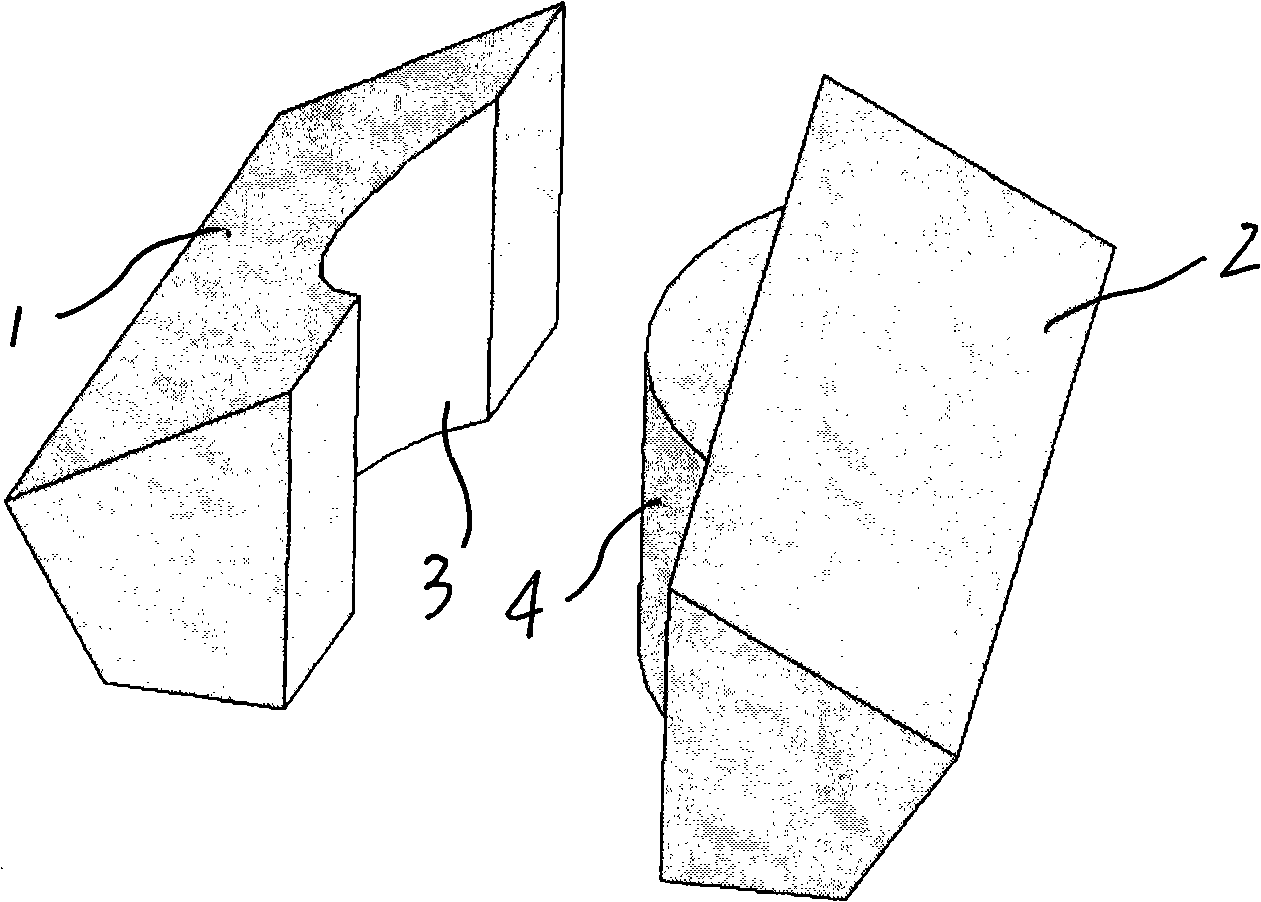

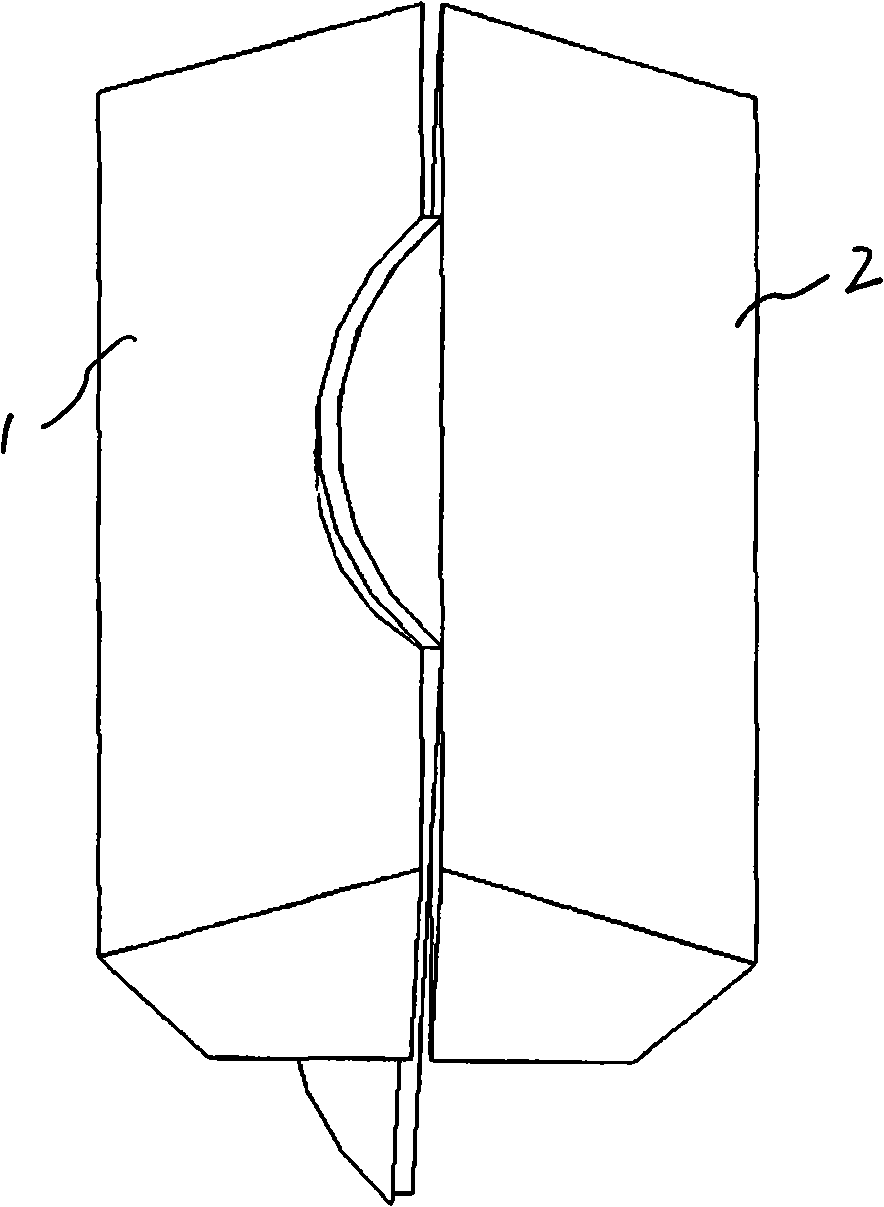

[0013] See attached Figure 1~3 As shown, this fixture for axial tension and compression fatigue test of metal thin-walled pipe samples can match the plate fixture of high frequency fatigue testing machine, and its feature is that it is composed of a pair of wedge-shaped clamps with concave and convex surfaces respectively. Consisting of blocks 1 and 2, wedge-shaped clamping blocks 1 and 2 with concave and convex surfaces contact with the thin-walled pipe sample according to the specific radian of the sample. Design a concave surface 3 and a convex surface 4, and wedge-shaped clamping blocks with convex surfaces The thickness of the 2 is greater than that of the wedge-shaped clamping block 1 with a concave surface. After the concave-convex surface is clamped, the center of gravity of the arc surface is just located at 1 / 2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com