Charging machine

A charger and main charging technology, applied in the direction of collectors, electric vehicles, electrical components, etc., can solve the problems of damage, the inability to convert the second stage of the battery pack to the third stage, the thermal runaway of battery charging, etc., to meet the charging requirements. , to avoid the effect of thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

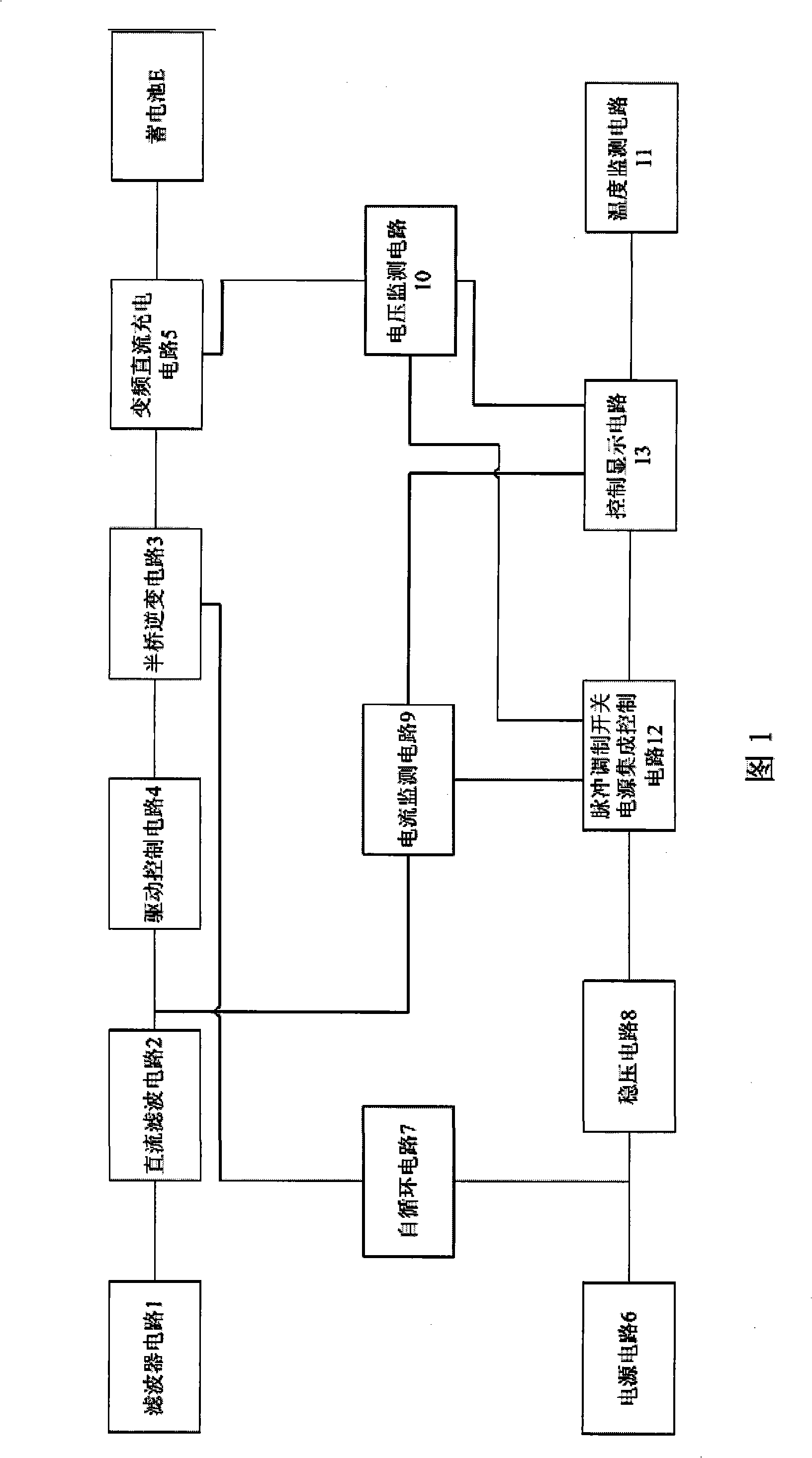

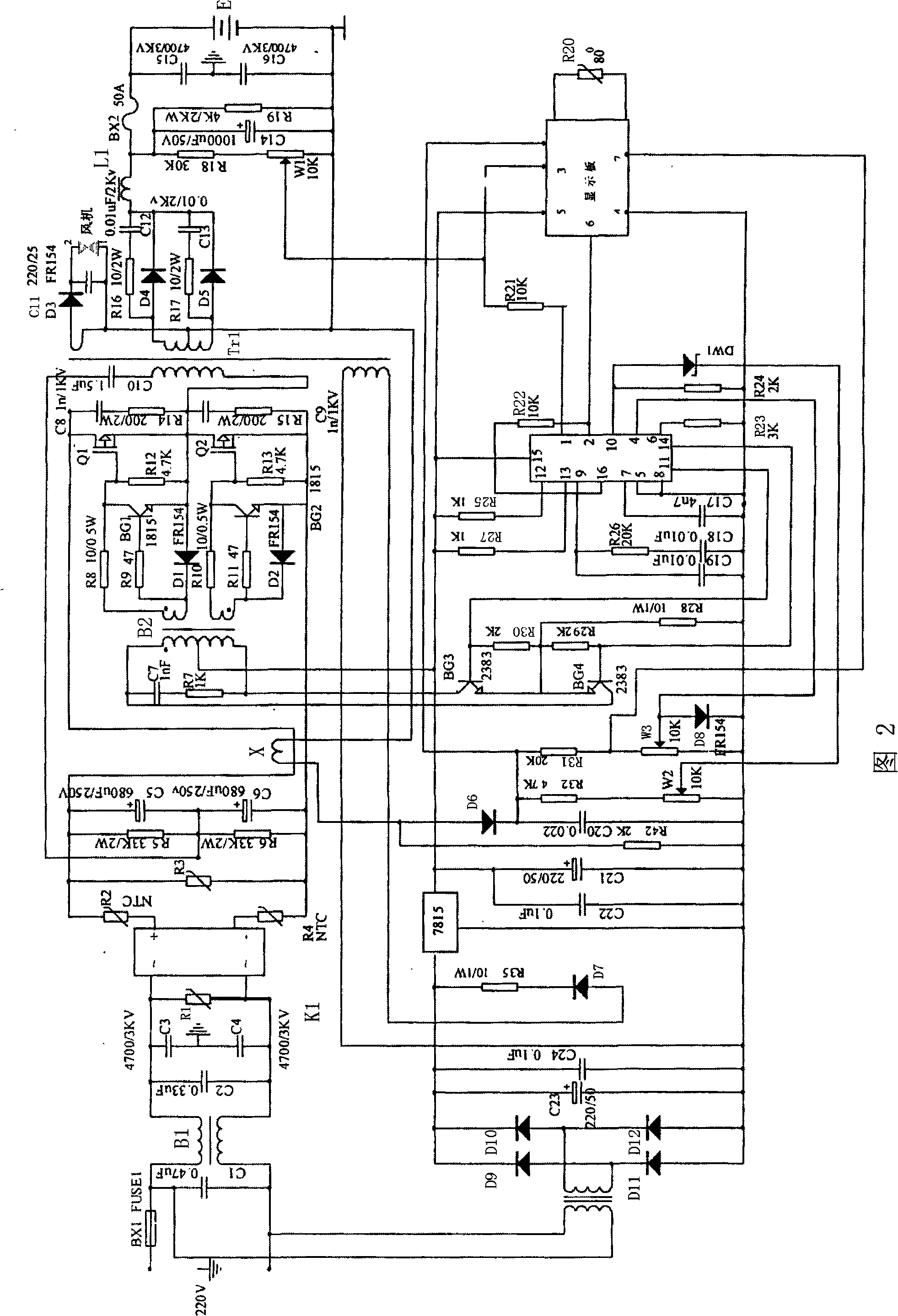

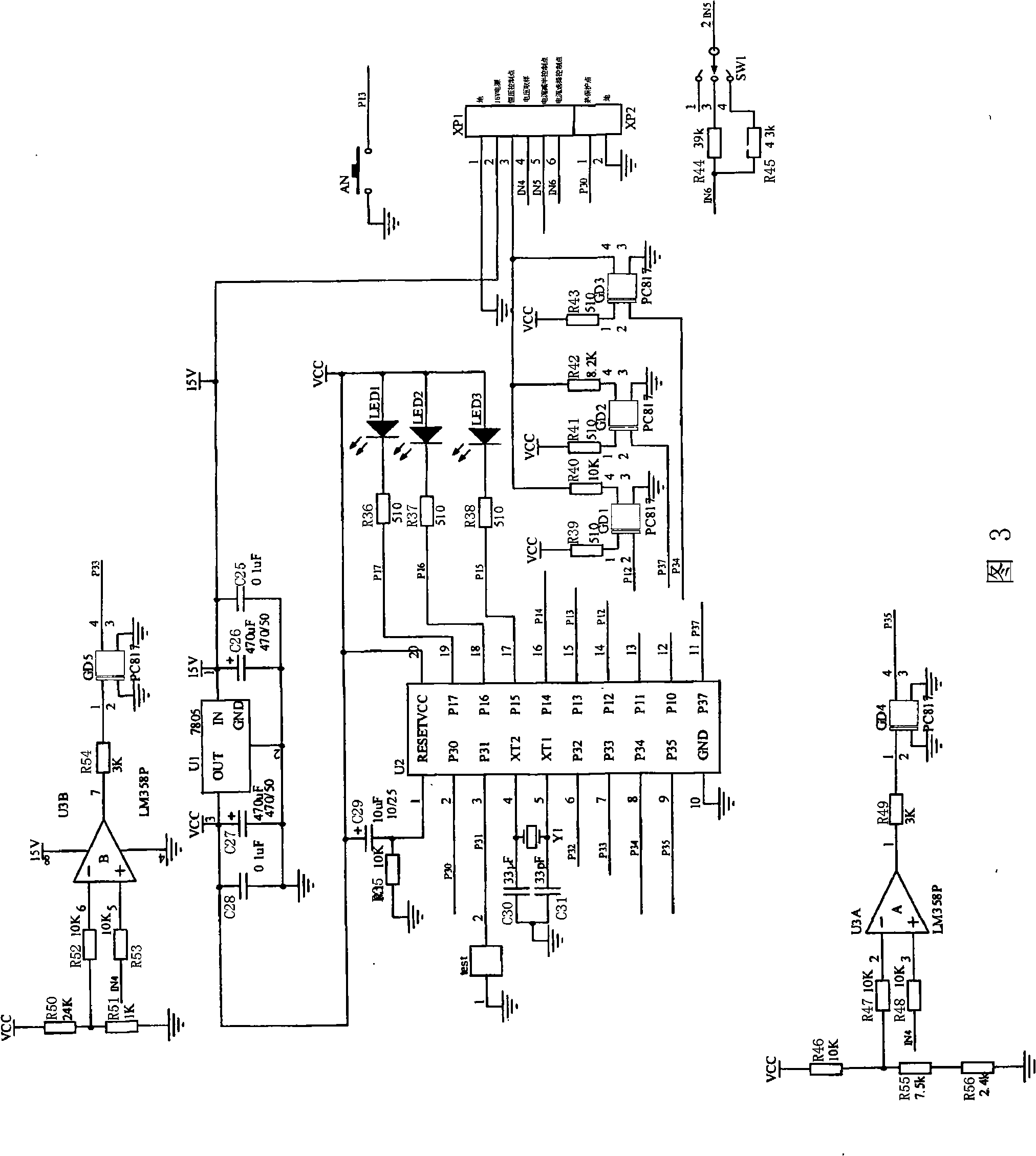

[0029] Referring to Fig. 1, the charger includes a main charging circuit and a charging control circuit, the main charging circuit includes a filter circuit 1, a rectification filter circuit 2, a pulse voltage divider circuit, a half-bridge inverter circuit 3, a drive control circuit 4, High-frequency rectification and charging circuit 5, the charging control circuit includes a power supply circuit 6, a voltage stabilizing circuit 8, a self-circulation circuit 7, a current monitoring circuit 9, a voltage monitoring circuit 10, a temperature monitoring circuit 11, a control display circuit 13 and a pulse modulation switch Power integrated control circuit 12.

[0030] After the filter circuit 1 filters the grid voltage 220V or 110V input to the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com