Engine oil cooling and filtrating device

An oil cooling and oil filter technology, which is used in engine cooling, installation/connection of lubricant purification devices, mechanical equipment, etc. problems, to facilitate replacement and post-maintenance, ensure supply, and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

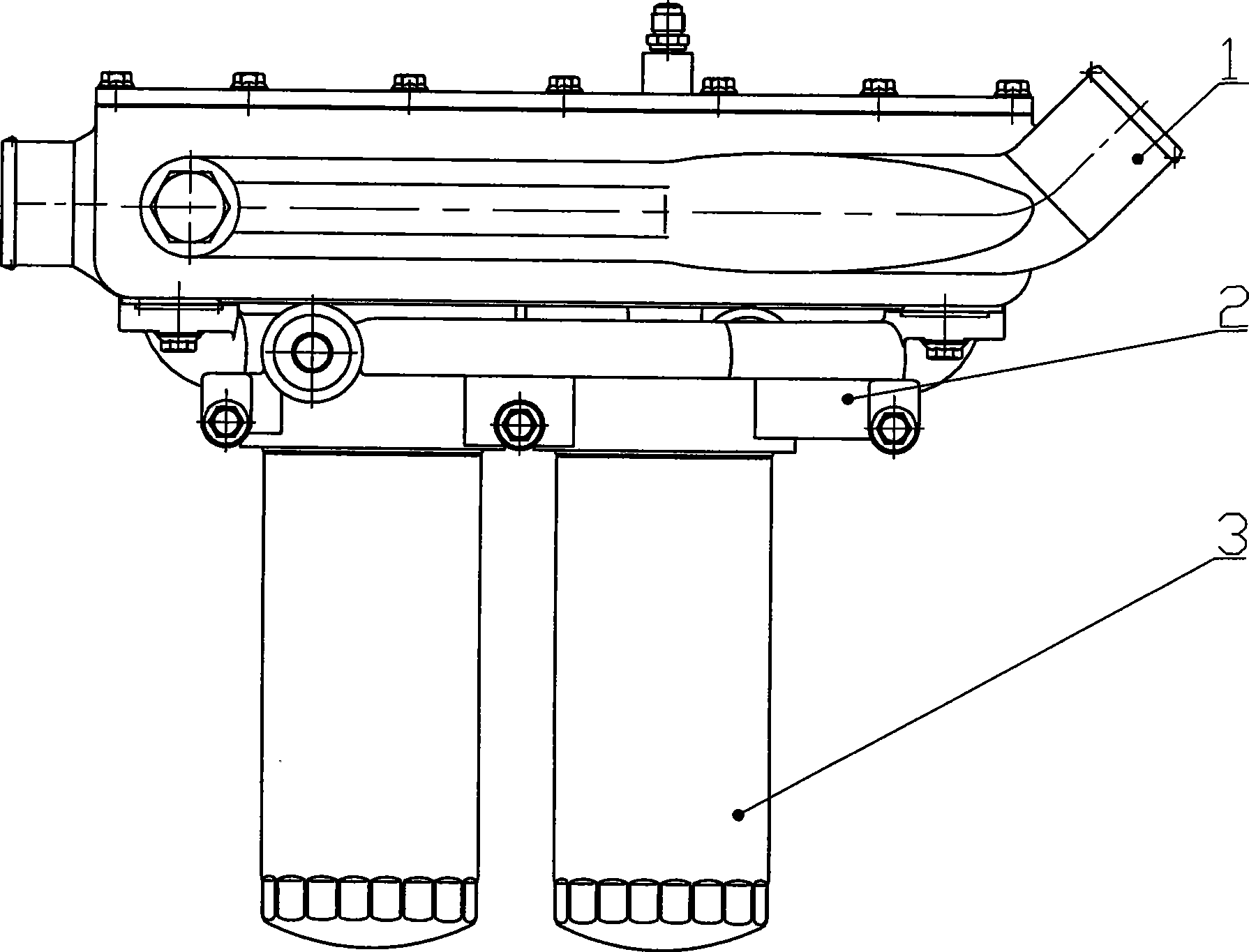

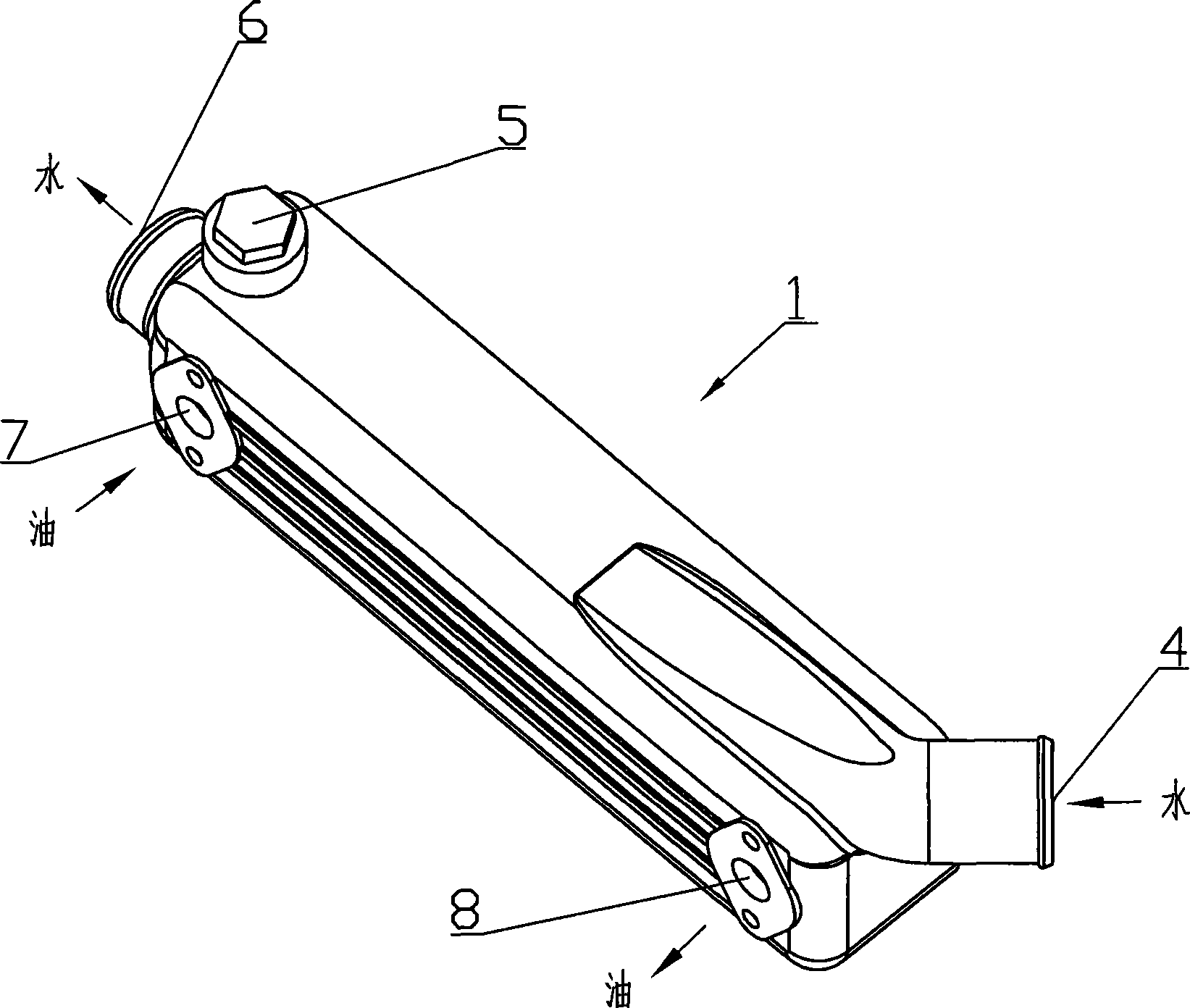

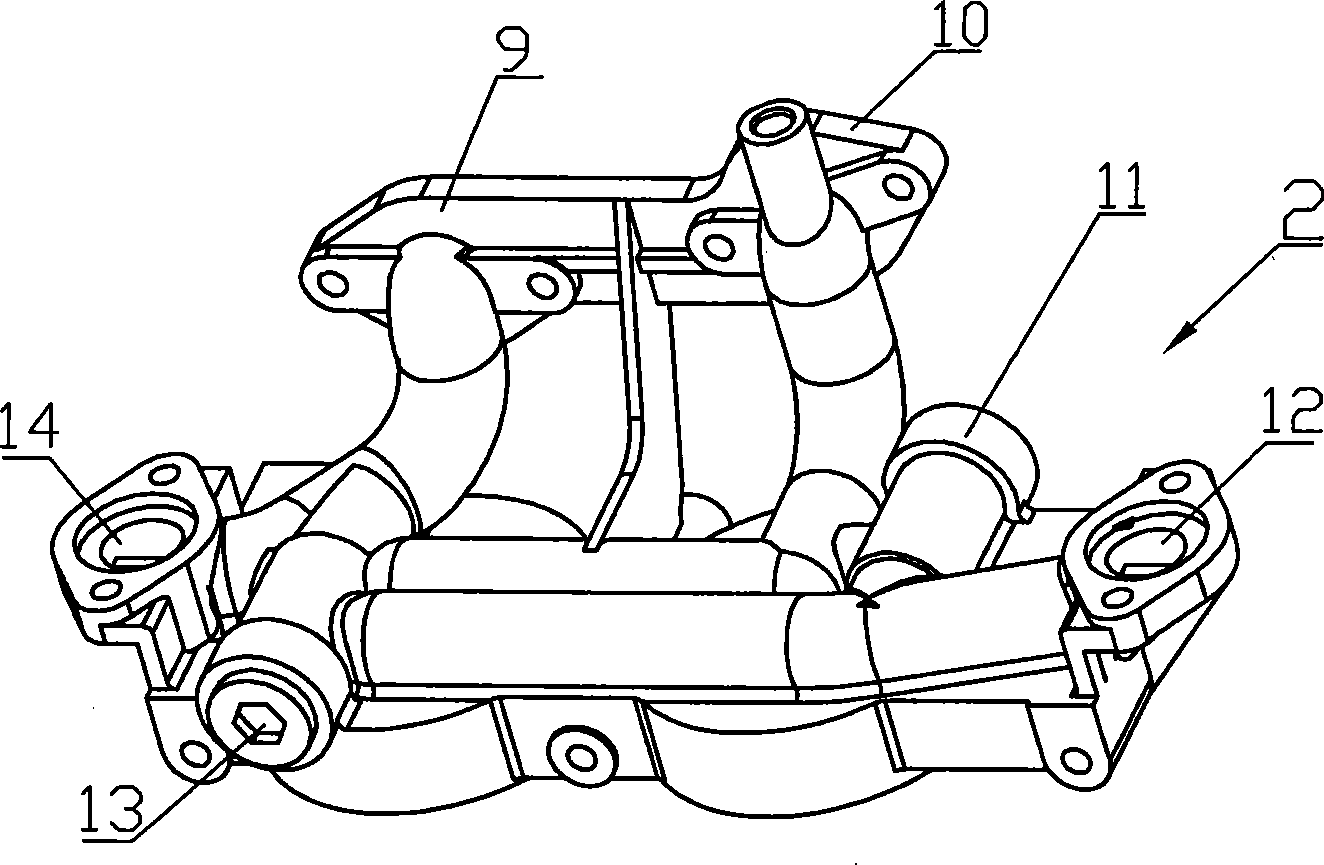

[0022] Figure 1 to Figure 7 As shown, including oil cooler 1, oil filter seat 2, oil filter 3, water inlet 4, drain bolt 5, water outlet 6, oil cooler inlet 7, oil cooler outlet 8, Oil inlet 9 on oil filter seat, oil outlet 10 on oil filter seat, safety valve 11, oil inlet 12 under oil filter seat, bypass valve 13, oil outlet under oil filter seat 14. Oil filter inlet passage 15, oil filter outlet passage 16, bypass hole 17, etc.

[0023] like figure 1 As shown, the present invention includes a machine oil cooler 1 and a machine oil filter 3, and the machine oil cooler 1 and the machine oil filter 3 are installed on the machine oil filter seat 2 respectively. Described machine oil filter 3 is provided with two, and two machine oil filters 3 are screw-mounted on the machine oil filter seat 2.

[0024] like figure 2 As shown, the oil cooler 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com