Gas nozzle of stalk etherealization heating stove for curing tobacco

A technology for gas nozzles and heating furnaces, which is applied to gas fuel burners, lighting and heating equipment, tobacco, etc. It can solve problems such as low heat exchange efficiency, burnout of gas nozzles, and insufficient gas combustion, so as to increase the combustion area, Extended service life, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

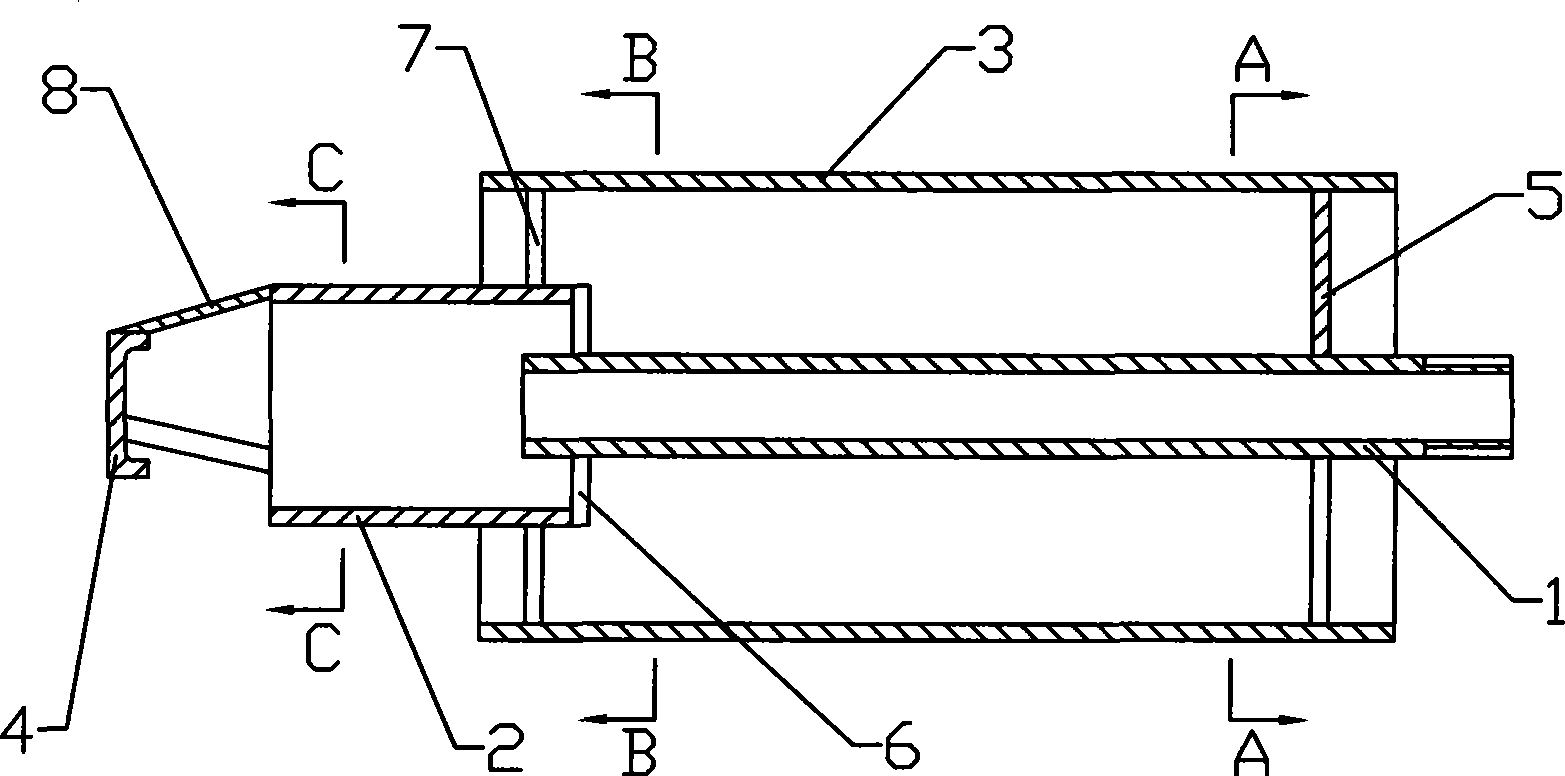

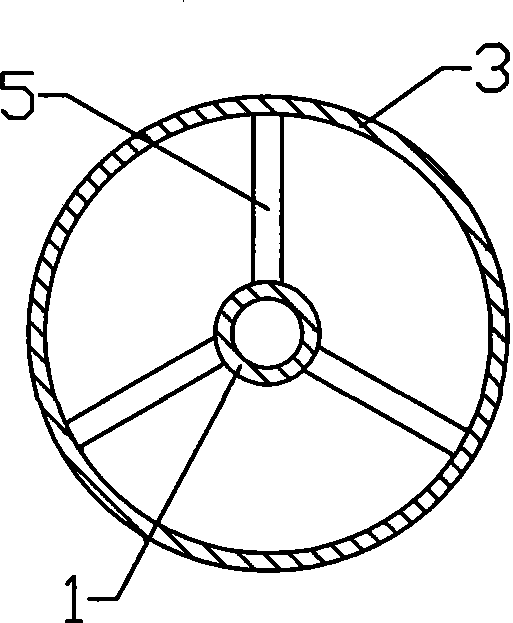

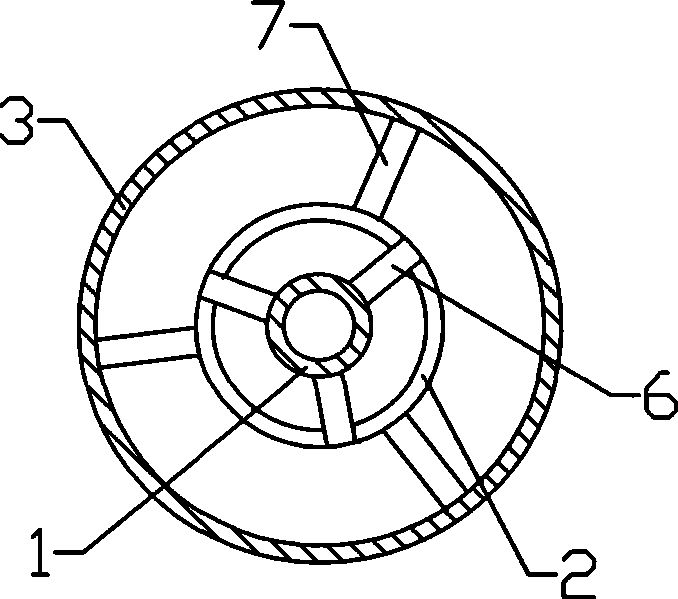

[0017] Examples such as figure 1 Shown is a gas nozzle for a straw gasification heating furnace for flue-cured tobacco, which includes an air inlet pipe 1, the air inlet pipe 1 includes an air inlet end and an air outlet end, the air inlet end of the air inlet pipe 1 is provided with a connecting thread, and the air outlet end of the air inlet pipe 1 passes through The second support plate 6 is fixedly connected with one end of the combustion pipe 2, and the outlet end of the air intake pipe 1 extends to the inside of the combustion pipe 2, and the other end of the combustion pipe 2 is connected with a top cover 4 by a fourth support plate 8, and the periphery of the top cover 4 is provided with a top cover 4. There are protrusions, the circumference of the top cover is less than the circumference of the combustion tube, which is 3 / 4 of the circumference of the combustion tube in this embodiment, there is an interval between the top cover 4 and the end of the combustion tube 2,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap