Detection device for bearing ball-separating holder assembly machine after riveting press

A detection device and cage technology, applied in the direction of mechanical bearing testing, bearing components, shafts and bearings, etc., can solve the problems of easy missed detection, low detection efficiency, and inability to fully inspect bearings, so as to reduce labor intensity and achieve accurate detection. The effect of high rate and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

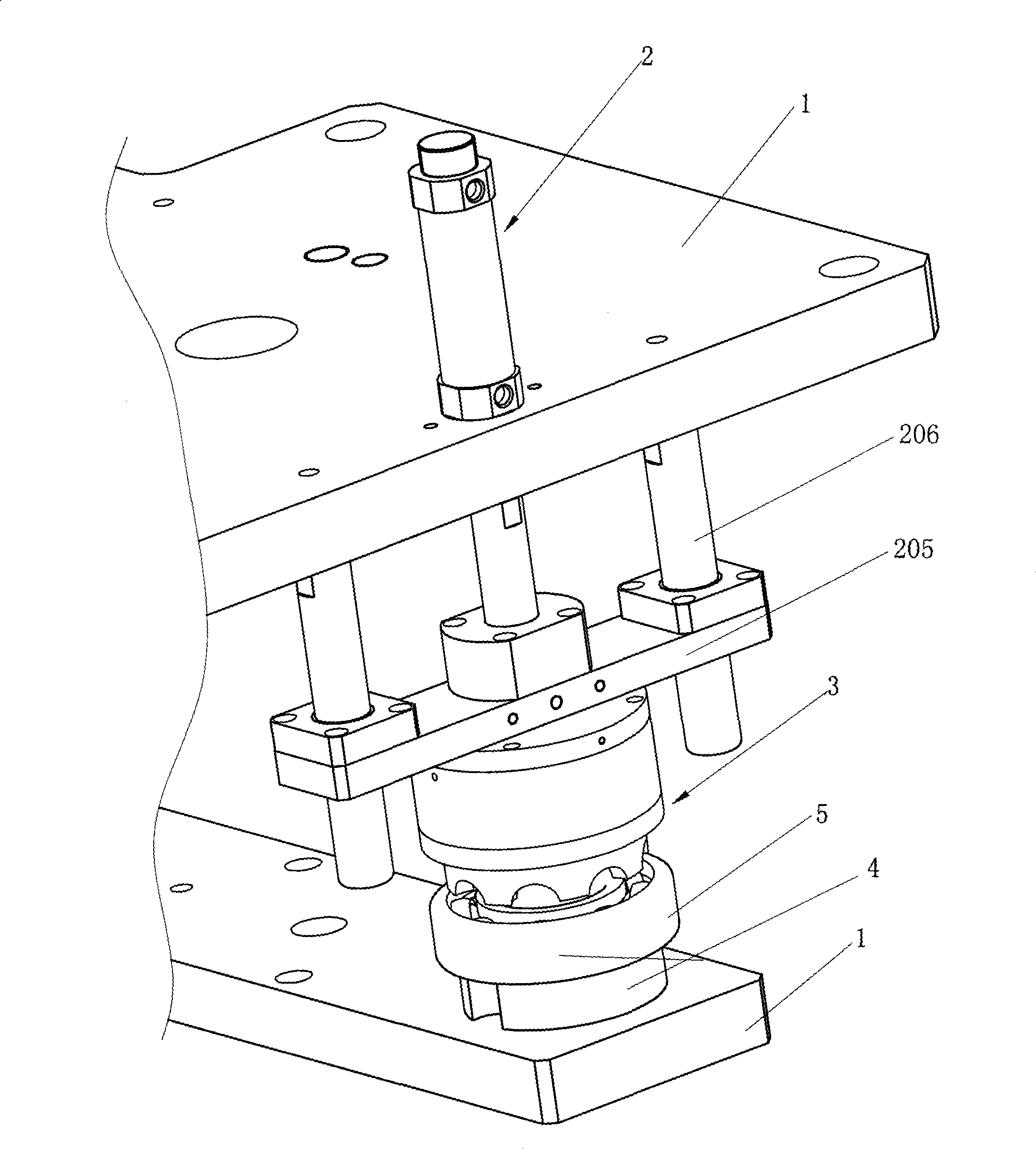

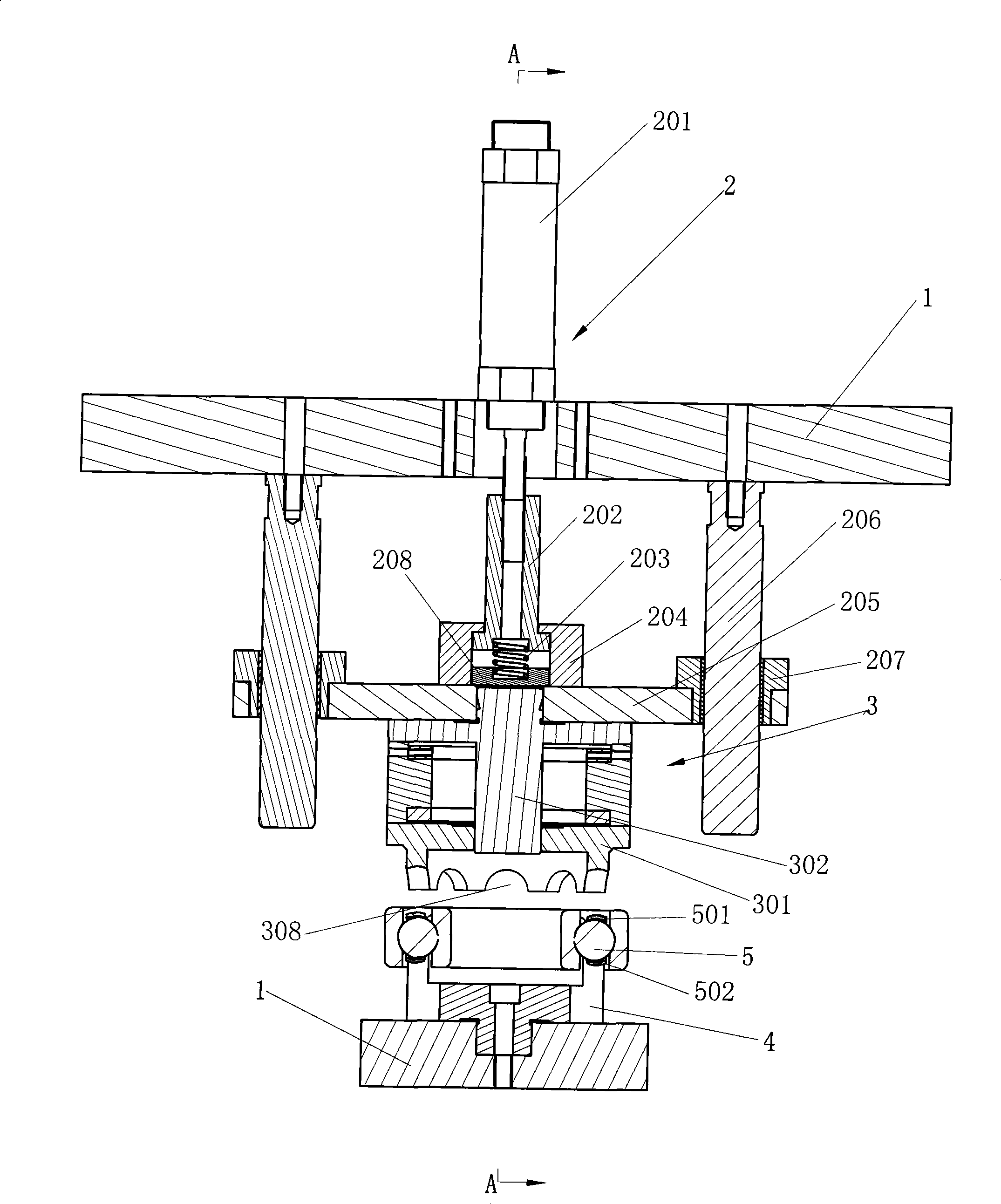

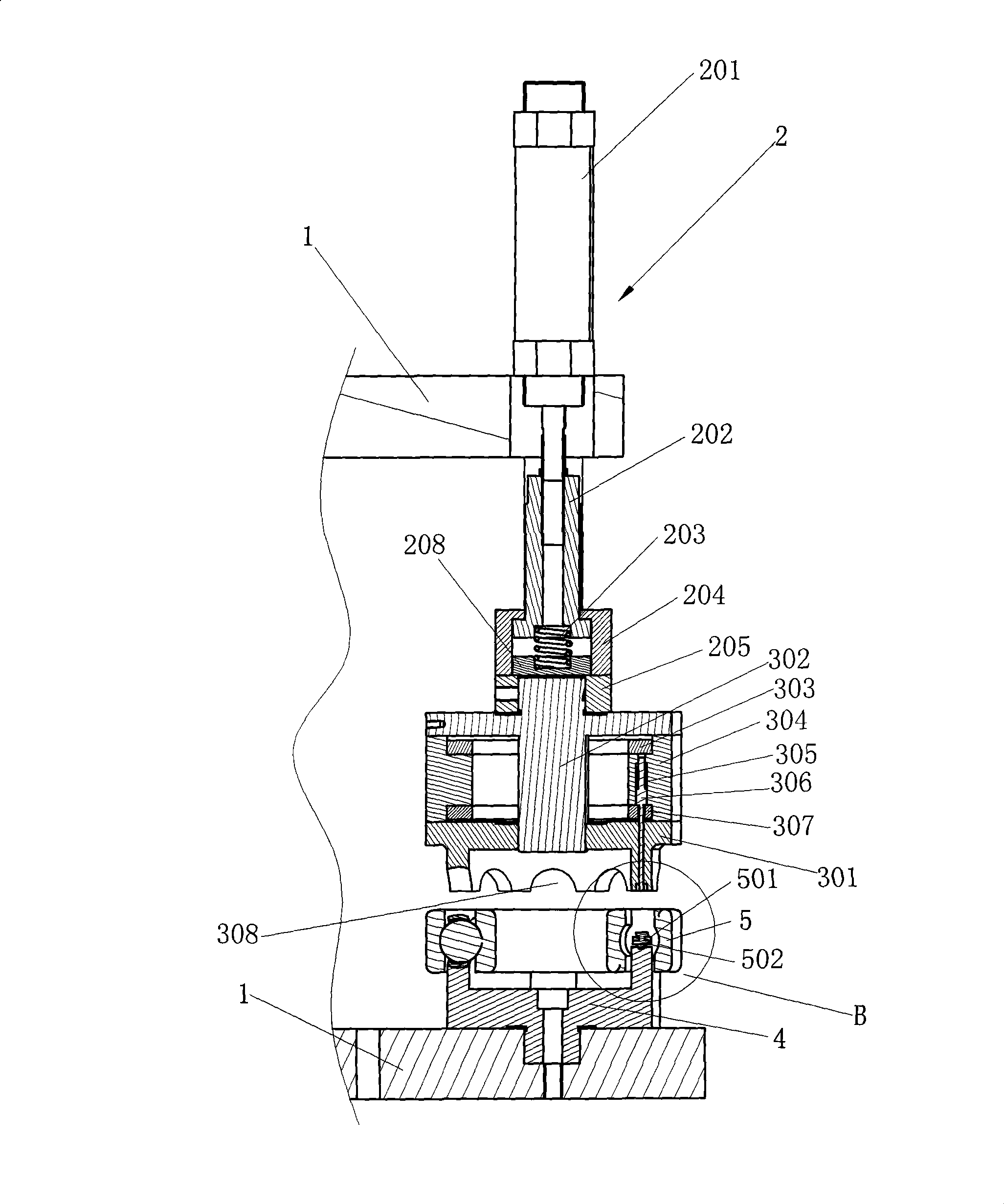

[0019] Such as figure 1 , 2 , shown in 3, the present invention comprises frame 1 and electric control system (not marked in the figure), and lifting mechanism 2 is installed above frame 1, and lifting mechanism 2 comprises the cylinder 201 that cylinder body device is on the frame 1, and cylinder 201 The piston rod is connected to one end of the connecting rod 202, the other end of the connecting rod 202 is sleeved in the connecting block 204, a spring 203 is installed between the front end of the connecting rod 202 and the guide slider 205, the connecting block 204 is installed on the guide slider 205, and the guide The slider 205 is slidingly connected with the guide rod 206 installed on the frame 1. In this embodiment, a spacer 208 is installed between the spring 203 and the guide slider 205. One end of the spring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com