Slow-speed heavy-load fibrage composite self-lubricating bearing strip performance test machine

A fiber weaving, low-speed and heavy-load technology, which is applied in testing wear resistance, mechanical bearing testing, etc., can solve the friction and wear mechanism test performance optimization test is blank, the quality, performance and quality cannot be fully satisfied, and the test methods and conditions are outdated and other problems, to achieve the effect of compact structure, beautiful appearance, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

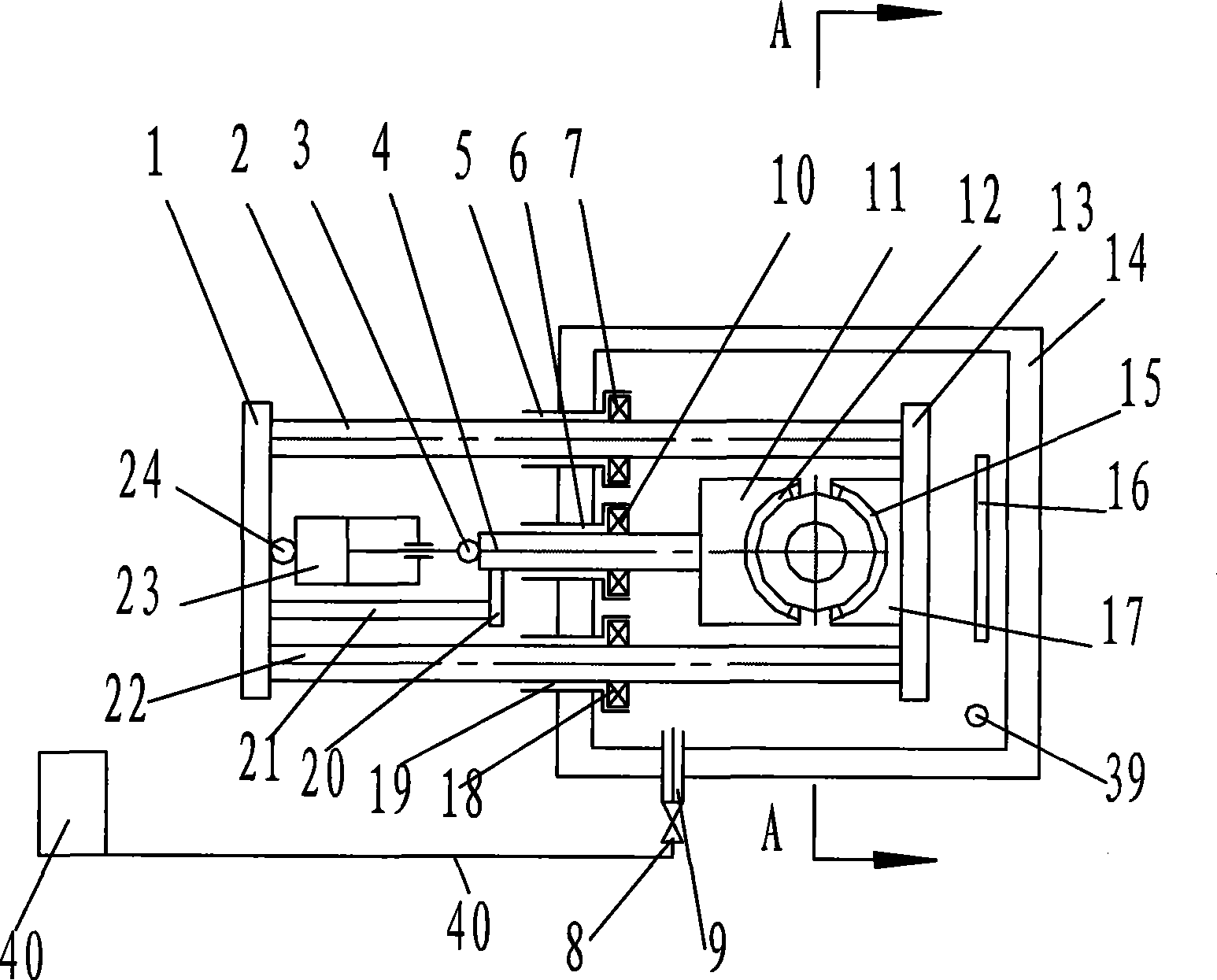

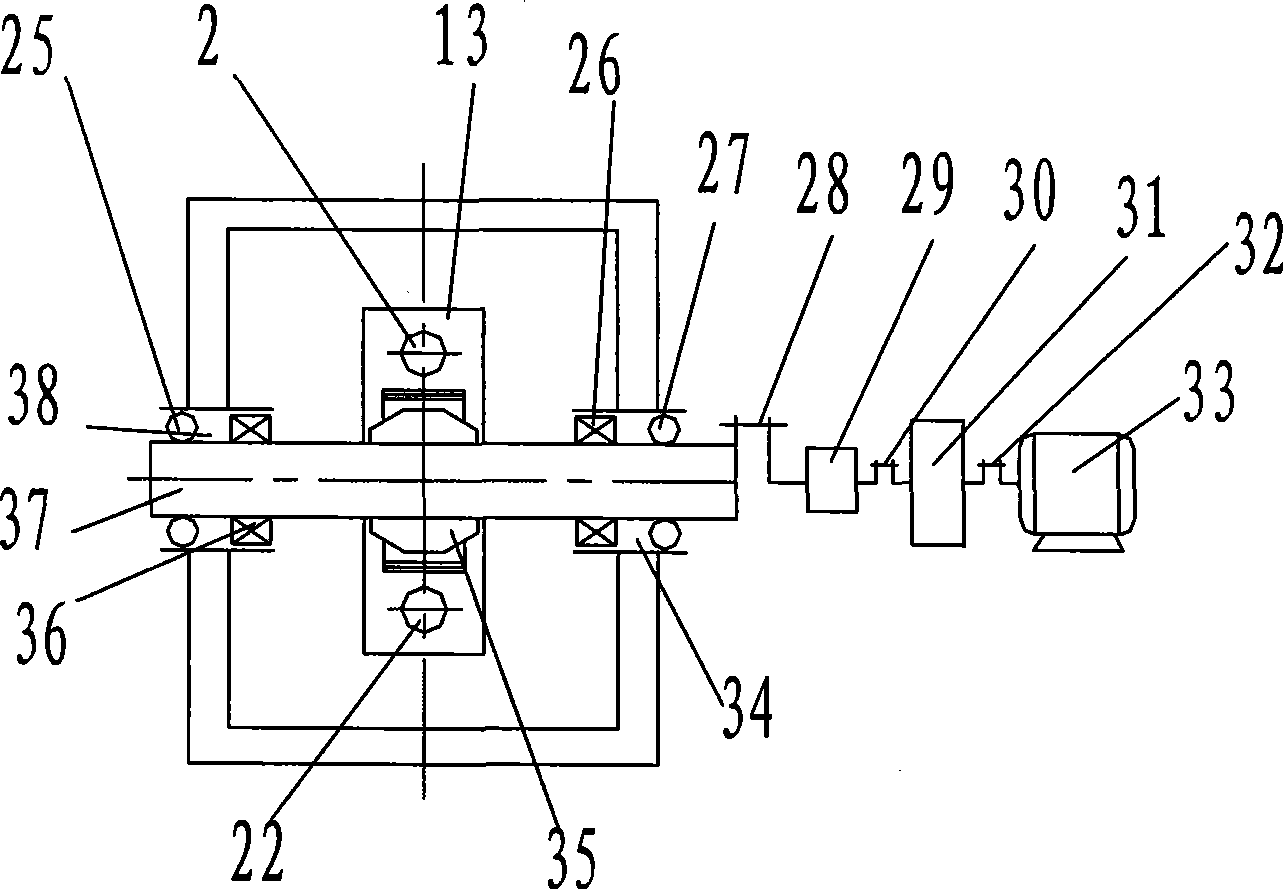

[0011] figure 1 , figure 2 It is an embodiment disclosed by the present invention. There are five holes on the box wall of the airtight box 14: the first box hole 5, the second box hole 6, the third box hole 19, and the fourth box hole. Hole 34, the fifth box hole 38, the axes of the first box hole 5, the second box hole 6, and the third box hole 19 are in the same plane and are parallel to each other. The fourth box hole 34, the fifth box hole The axis of the box hole 38 is on the same straight line, the axis of the first box hole 5, the second box hole 6, the third box hole 19 and the axis of the fourth box hole 34, the fifth box hole 38 perpendicular to each other. In the fourth casing hole 34 and the fifth casing hole 38, a rotating shaft 37 is supported by the first bearing 25 and the second bearing 27, and one end of the rotating shaft 37 stretches out of the airtight casing 14. The end of the end is connected with the output shaft of the torque meter 29 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com