Water pump impeller

A water pump impeller and impeller technology, which is applied in the field of water pump impellers, can solve problems such as low efficiency, difficult adjustment, and large energy consumption, and achieve the effects of improving cooling effect, reducing installation clearance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

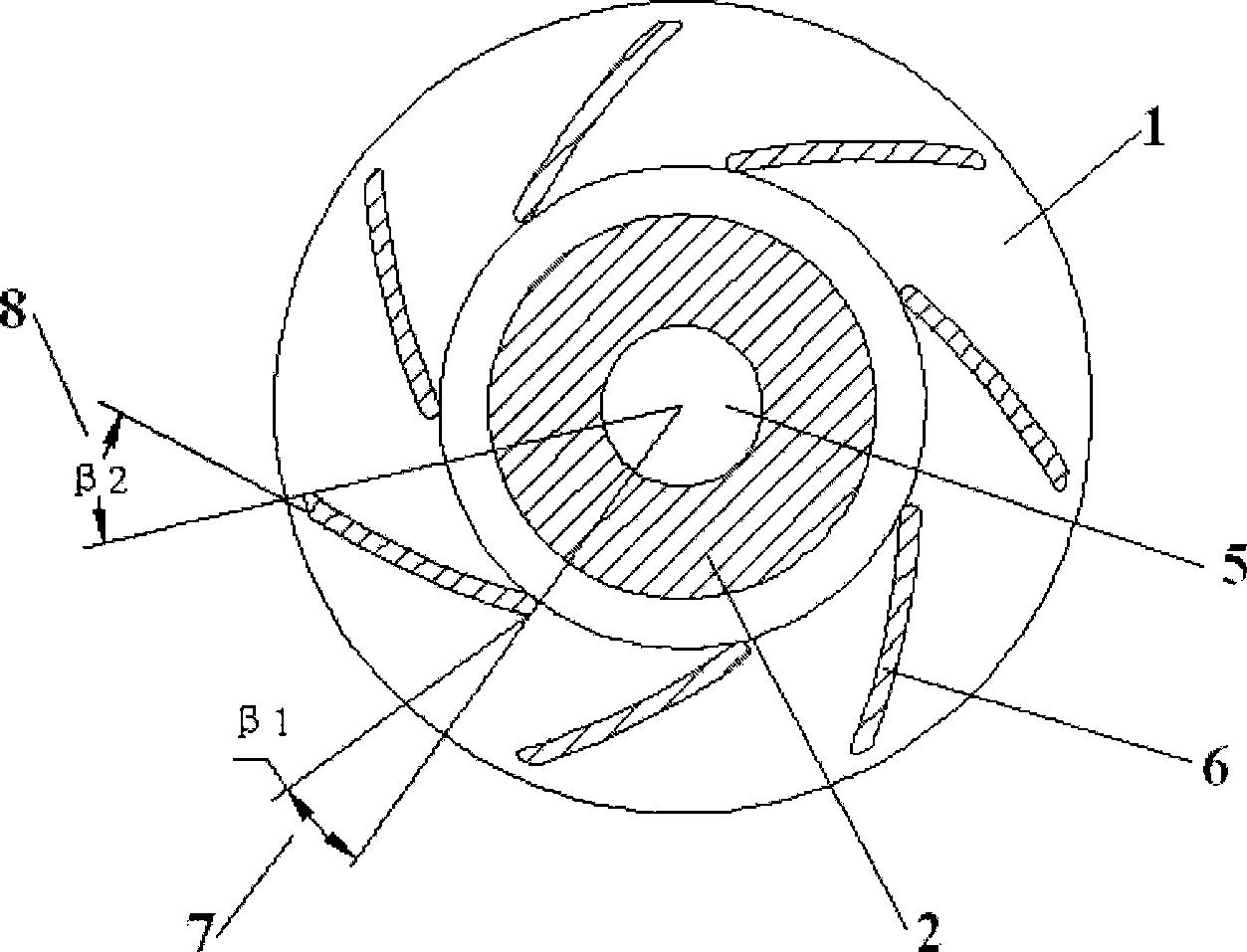

[0045] The β1 is 17°-19°; the β2 is 40°-44°.

[0046] Examples of possible combinations are:

[0047] β1=17°, β2=44°;

[0048] β1=17°, β2=40°;

[0049] β1=17°, β2=42°;

[0050] β1=19°, β2=42°;

[0051] β1=18°, β2=44°;

[0052] β1=18°, β2=40°;

[0053] β1=18°, β2=42°

[0054] β1=19°, β2=40°;

[0055] β1 = 19°, β2 = 44°; and so on.

[0056] When selecting, determine the values of β1 and β2 according to actual needs.

Embodiment 2

[0058] Furthermore, the β1 is 18°; the β2 is 42°. This is an optimal option, which can be adapted to applications under different conditions.

Embodiment 3

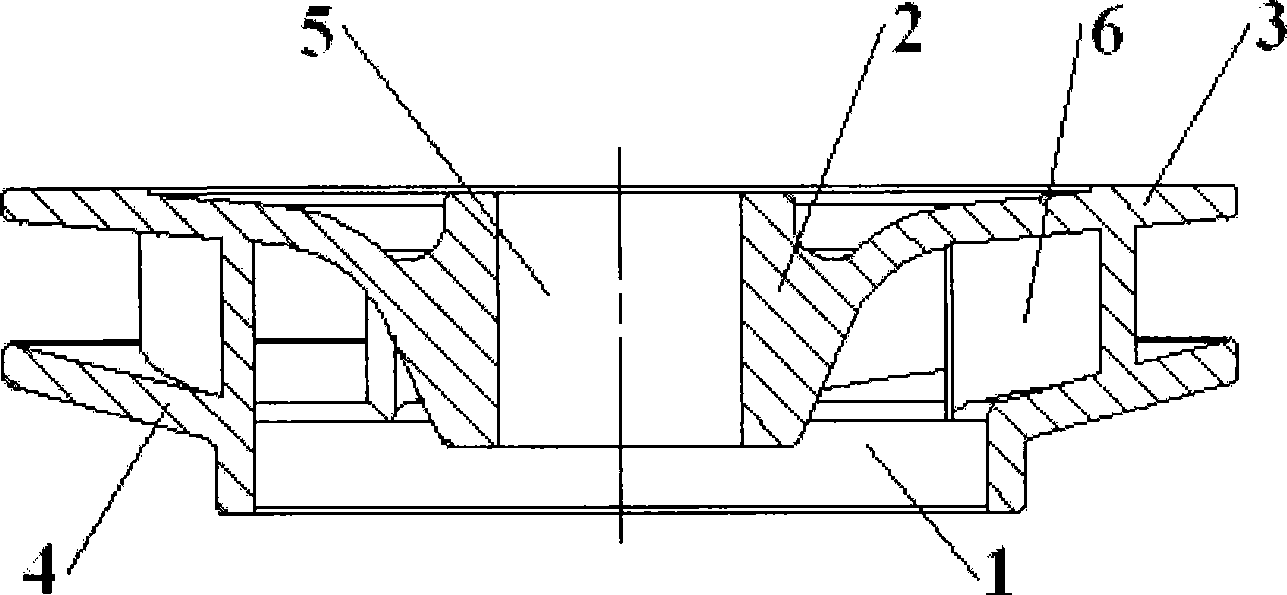

[0060] The water pump impeller 1 of the present invention is provided with an impeller front baffle 3 and an impeller rear baffle 4, and the shape of the impeller front baffle 3 and the impeller rear baffle 4 is an approximate disc shape coaxial with the water pump impeller 1 ; The blades 5 are located on the axial front and rear sides of the water pump impeller 1, and are respectively connected with the impeller front baffle 3 and the impeller rear baffle 4 as a whole.

[0061] This embodiment is to change the form of the impeller from the open structure in the prior art, so that the blades of the water pump are distributed between the two baffles, so that the clearance requirements between the impeller of the water pump and the volute are not so strict, reducing the The installation clearance between the pump and the volute; this form is calculated by a formula. The distance between the impeller of the water pump and the volute has little effect on the water pumping capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com