Secondary air nozzle of rotary kiln

A technology of rotary kiln and secondary air, applied in the direction of rotary drum furnace, combustion method, lighting and heating equipment, etc., can solve the problems of impeller and casing deformation, fan overcurrent, air duct deformation, etc., to avoid deformation or burning damage, prolong service life and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

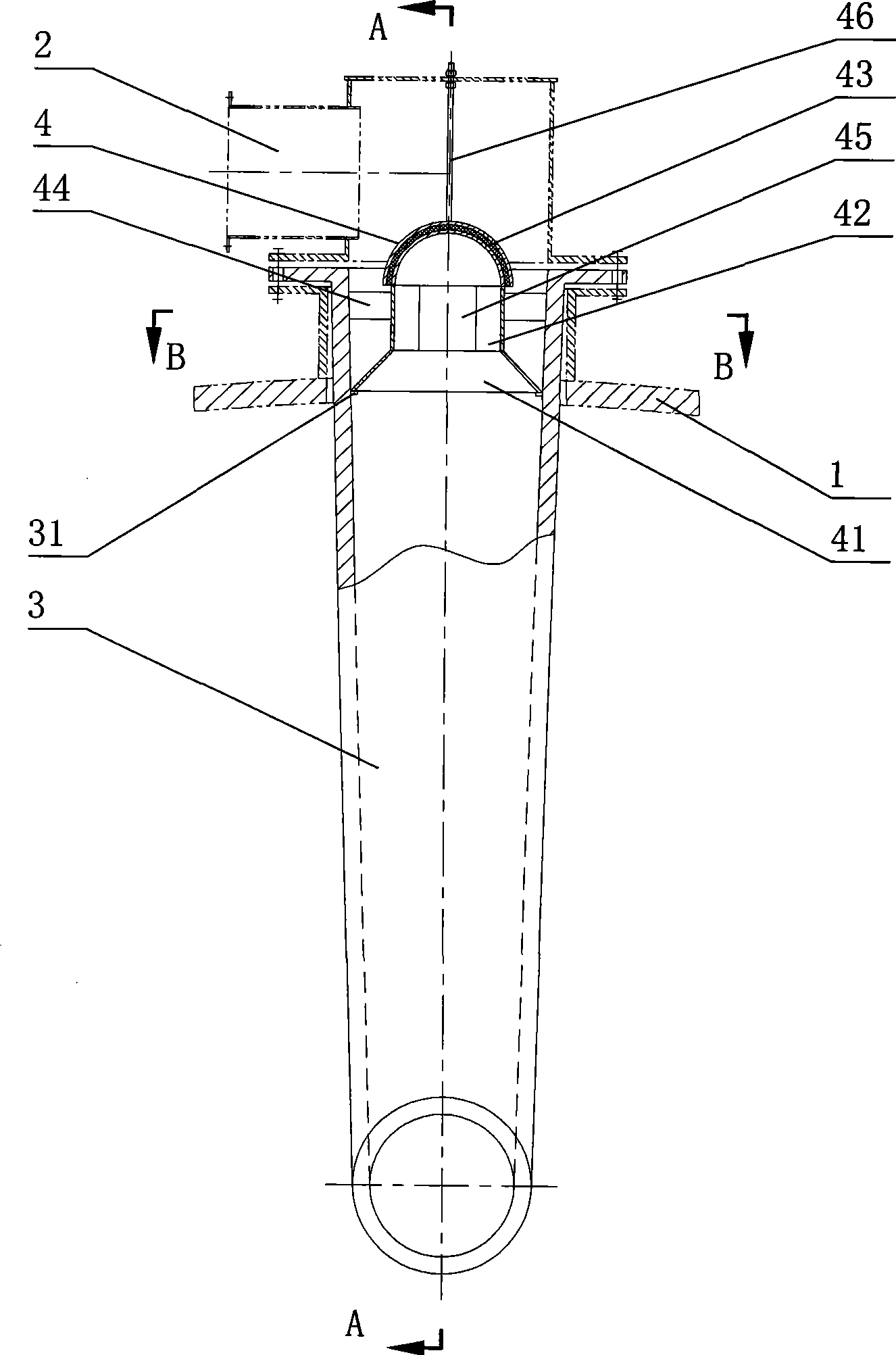

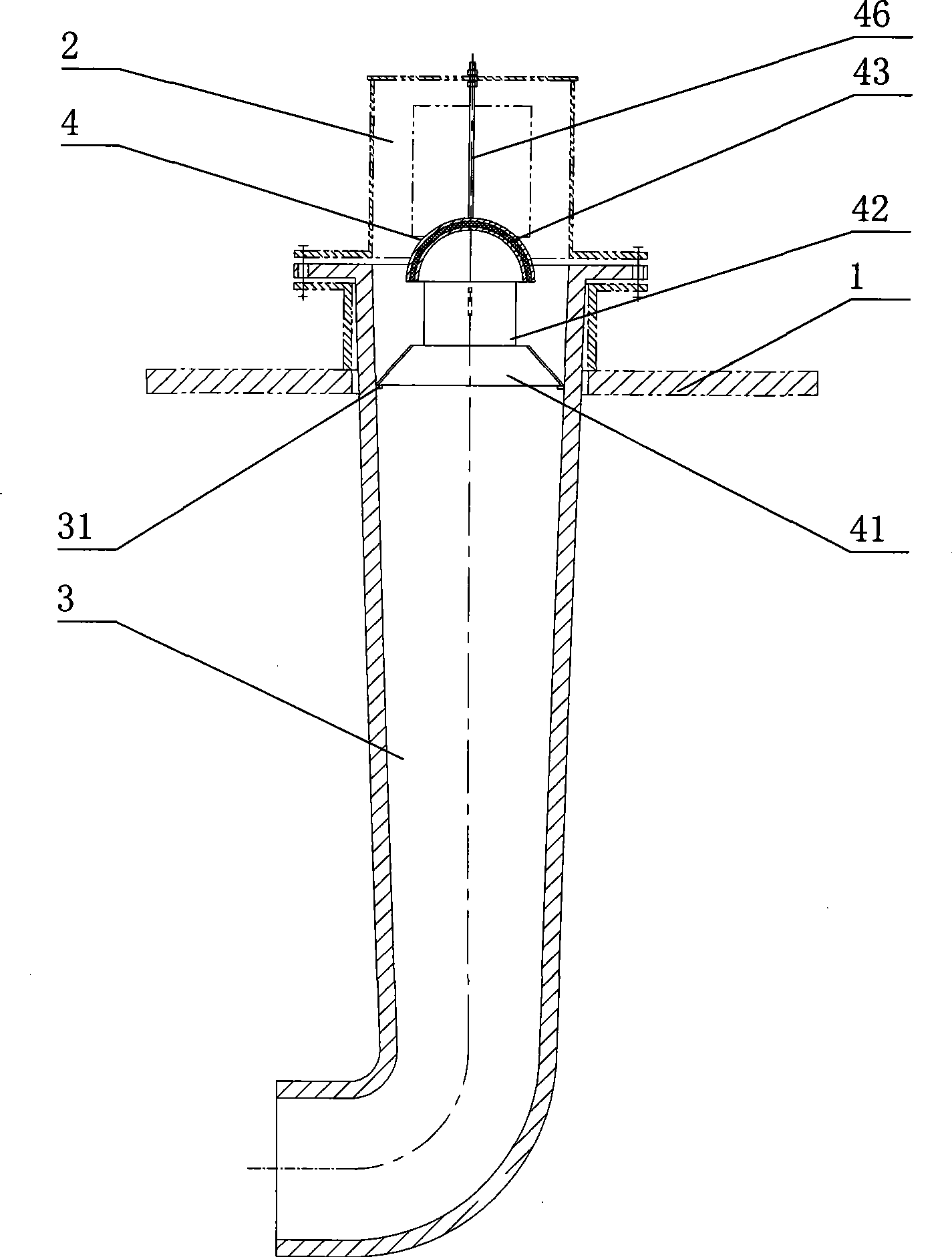

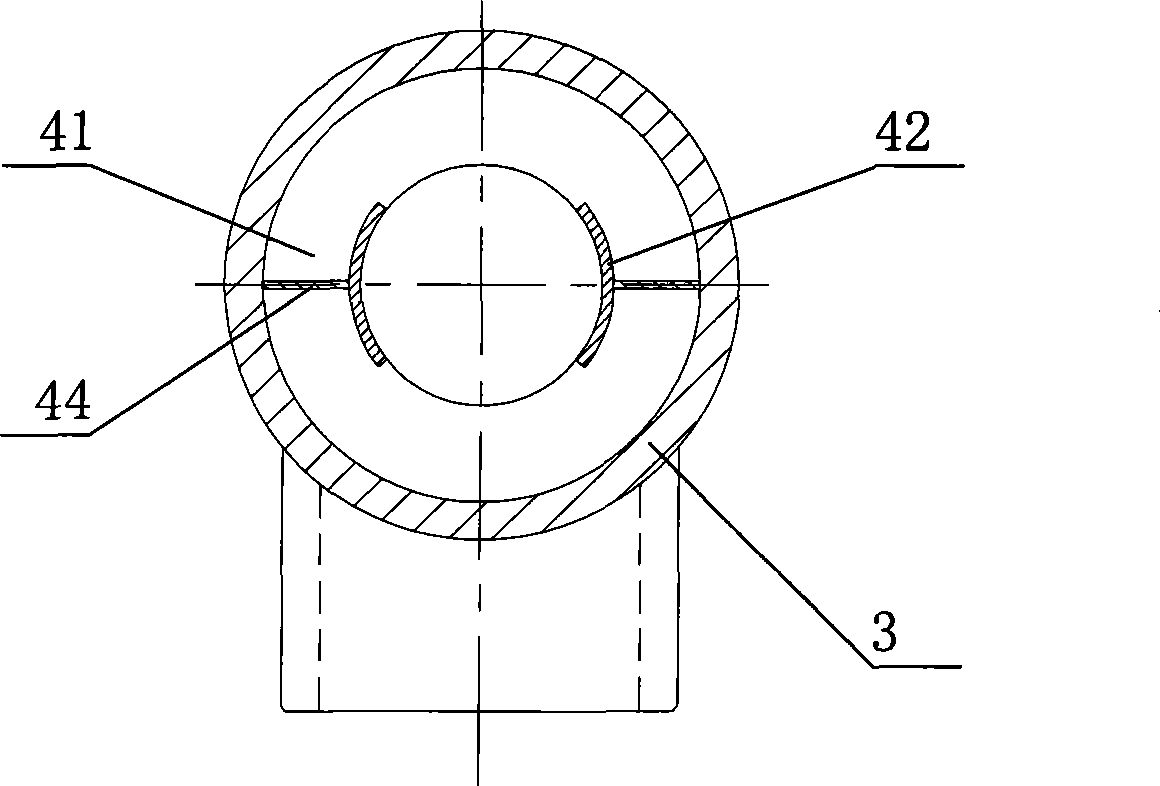

[0022] Such as Figure 1 to Figure 4 As shown, a rotary kiln secondary air nozzle includes a nozzle air channel 3 fixed on the rotary kiln skin 1 and communicated with the external air channel 2 of the rotary kiln. The nozzle air channel 3 is provided with a heat insulating material retaining member 4, The heat insulation blocking member 4 is located at the end where the nozzle air duct 3 connects with the external air duct 2 of the rotary kiln. The heat-insulating blocking member 4 can effectively isolate part of the radiant heat inside the rotary kiln, and prevent the fuel coal 5 in a high-temperature combustion state from entering the external air channel 2 of the rotary kiln and the fan casing from the air channel of the nozzle, so as to avoid the external air channel 2 of the rotary kiln. and the fan are deformed or burned due to the influence of high temperature, so as to ensure the long-term, continuous and normal operation of the external air duct 2 and the fan of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com