Storage simulator

A simulator and storage technology, applied in the field of storage simulators, can solve problems such as evaluation, time-consuming and energy-consuming, and achieve the effects of enhanced efficiency, good usability, and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

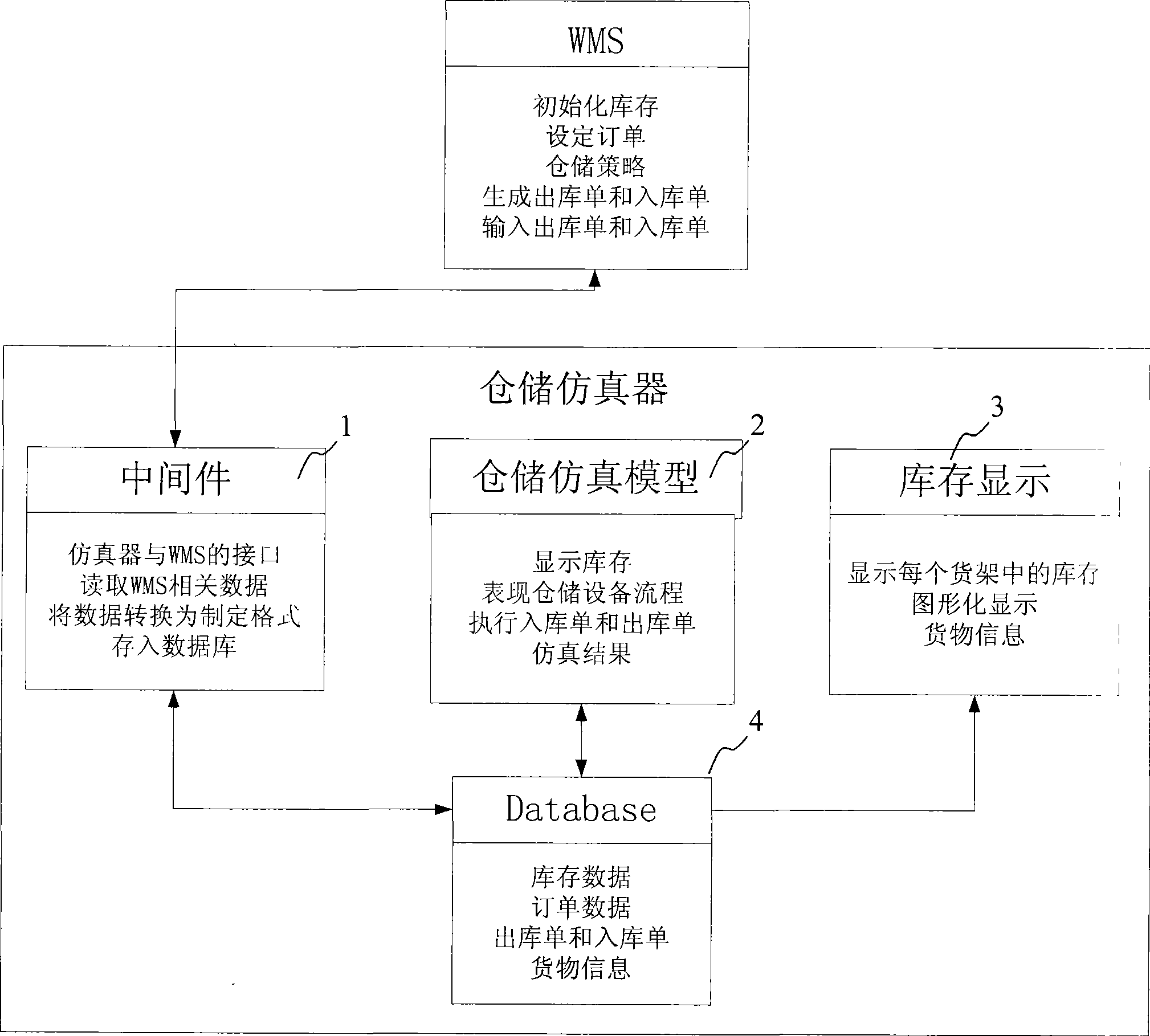

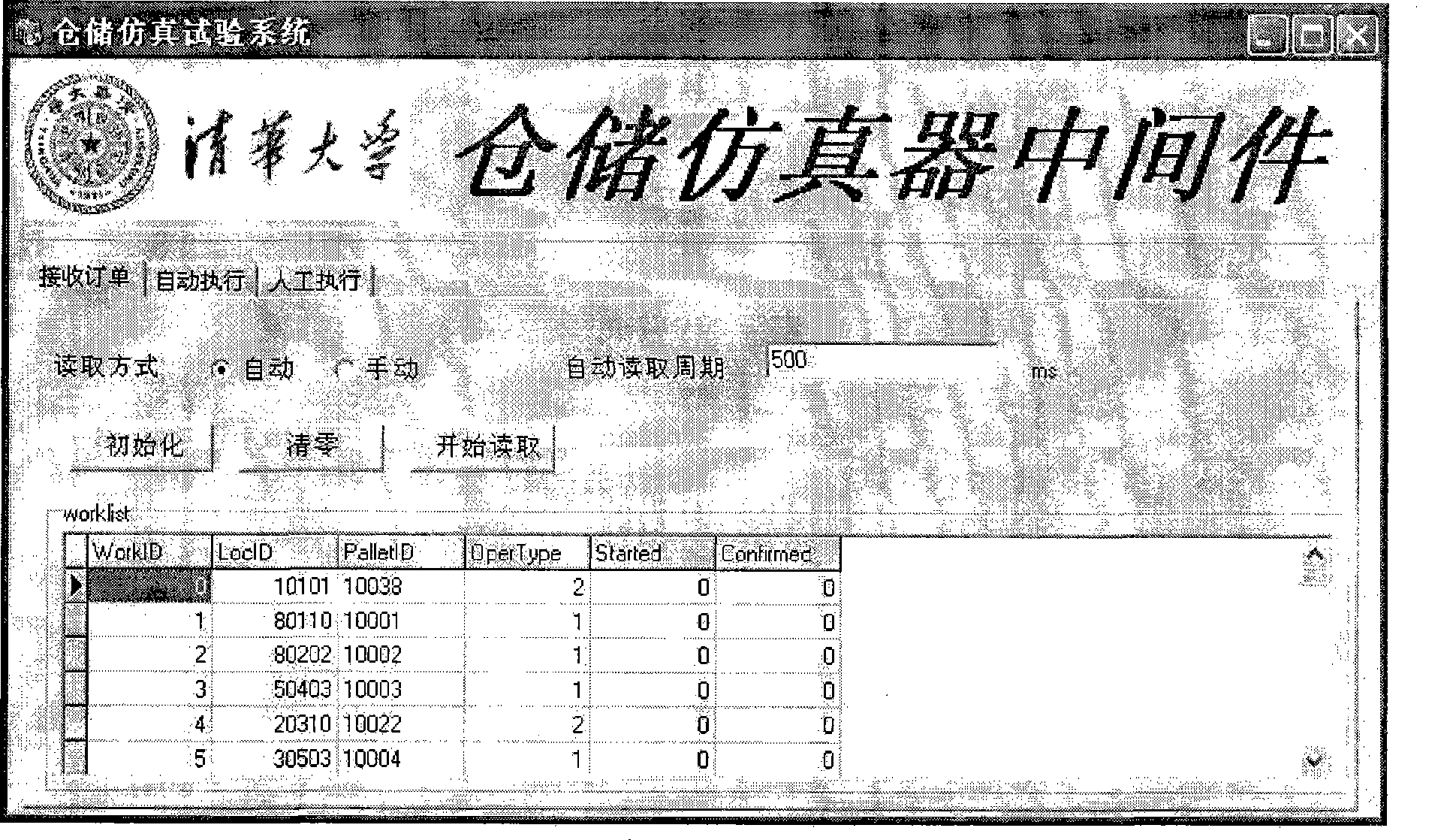

[0025] The core part of this warehousing simulator is a warehousing system simulation model established according to the operating logic of the actual warehousing system. This model can simulate the scheduling strategy and operation process of the warehousing system, so as to optimize the scheduling strategy and process of the warehousing system. The emulator can have both online and offline modes of operation. In the online mode, the emulator is directly connected to the WMS (Warehouse Management System), accepts the planning and scheduling information of the WMS, and performs real-time dynamic simulations such as storage and storage tasks, storage equipment operation, etc., and the simulation results are fed back to the WMS in real time. The offline mode is to run the emulator independently, and use the emulator instead of an actual storage system to simulate and analyze the storage system. In this way, it is possible to observe whether there are problems with the set storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com