Gantry type five-shaft linkage machine tool with series-parallel connection

A five-axis linkage machine tool, gantry-type technology, applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as weak structural rigidity, and achieve small structure occupation, compact and reasonable structure, and large rotation angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

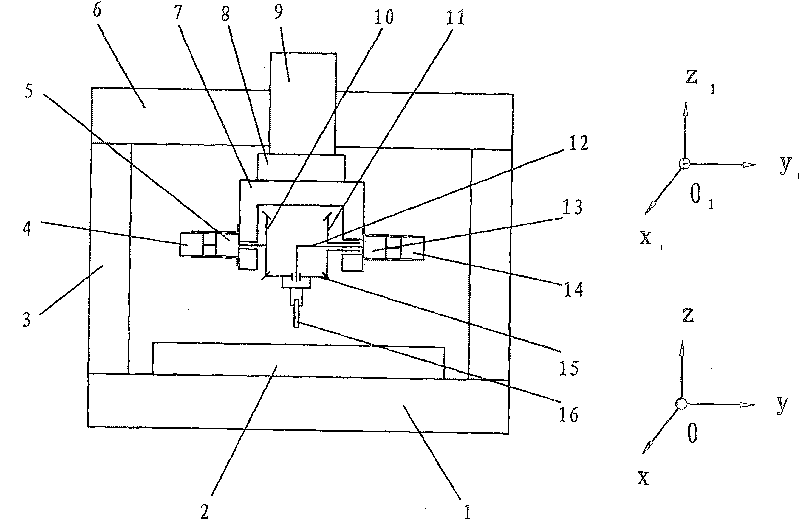

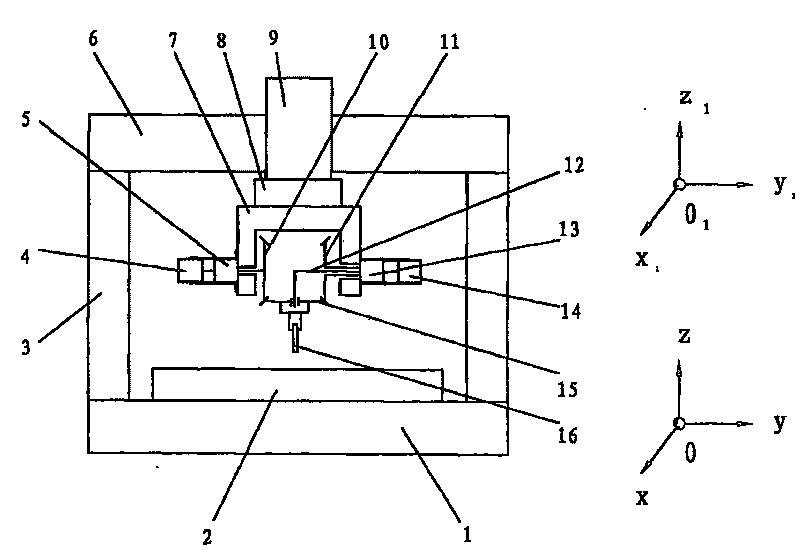

[0012] like figure 1 As shown, the horizontal sliding table 2 is installed on the machine tool base 1, and can generate horizontal movement of the X axis; the workpiece is installed on the horizontal sliding table 2; the column 3 is installed on the machine tool base 1; the beam 6 is installed on the column 3; the vertical The sliding table 9 is installed on the beam 6, and produces Y-axis movement; the rotating mechanism 8 is installed on the vertical sliding table 9, and produces Z-axis movement; the tool holder 7 is installed on the rotating mechanism 8, and the rotating mechanism 8 drives the tool holder 7 to generate Rotate 360° around the Z axis; the left motor 4 is installed on the left side of the tool holder 7, and drives the left bevel gear 10 to move, and the left bevel gear 10 drives the planetary gear 15 to rotate, thereby driving the tool 16 to rotate; the right motor 14 is installed on the tool holder 7 on the right side, and drive the tie rod 12 to swing; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com