Sludge drying apparatus

A drying equipment and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems that the sludge cannot be uniformly dried, difficult to be completely dried, and the sludge is difficult to dry, so as to save energy. The effect of drying time, shortening drying equipment and saving heating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

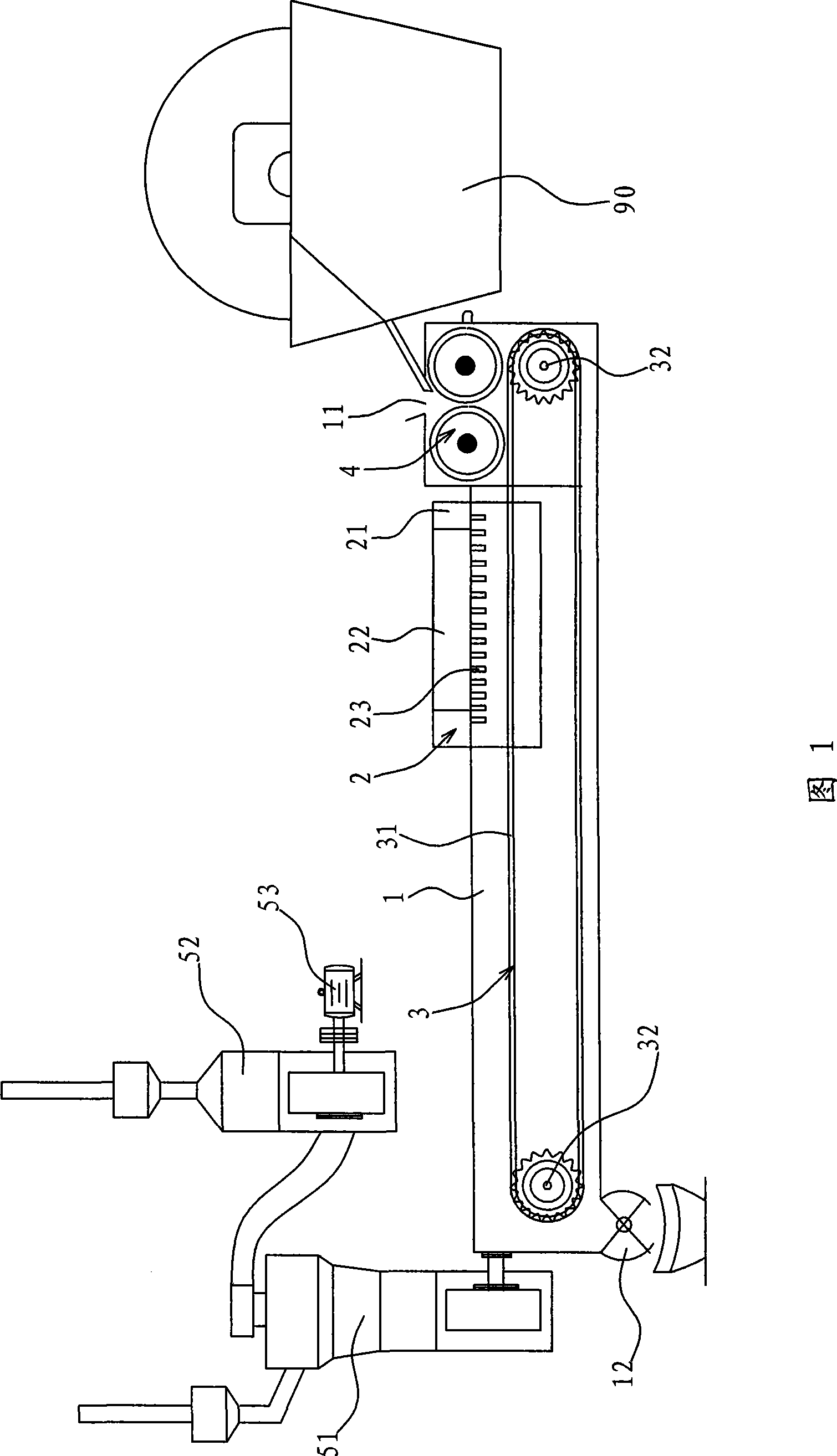

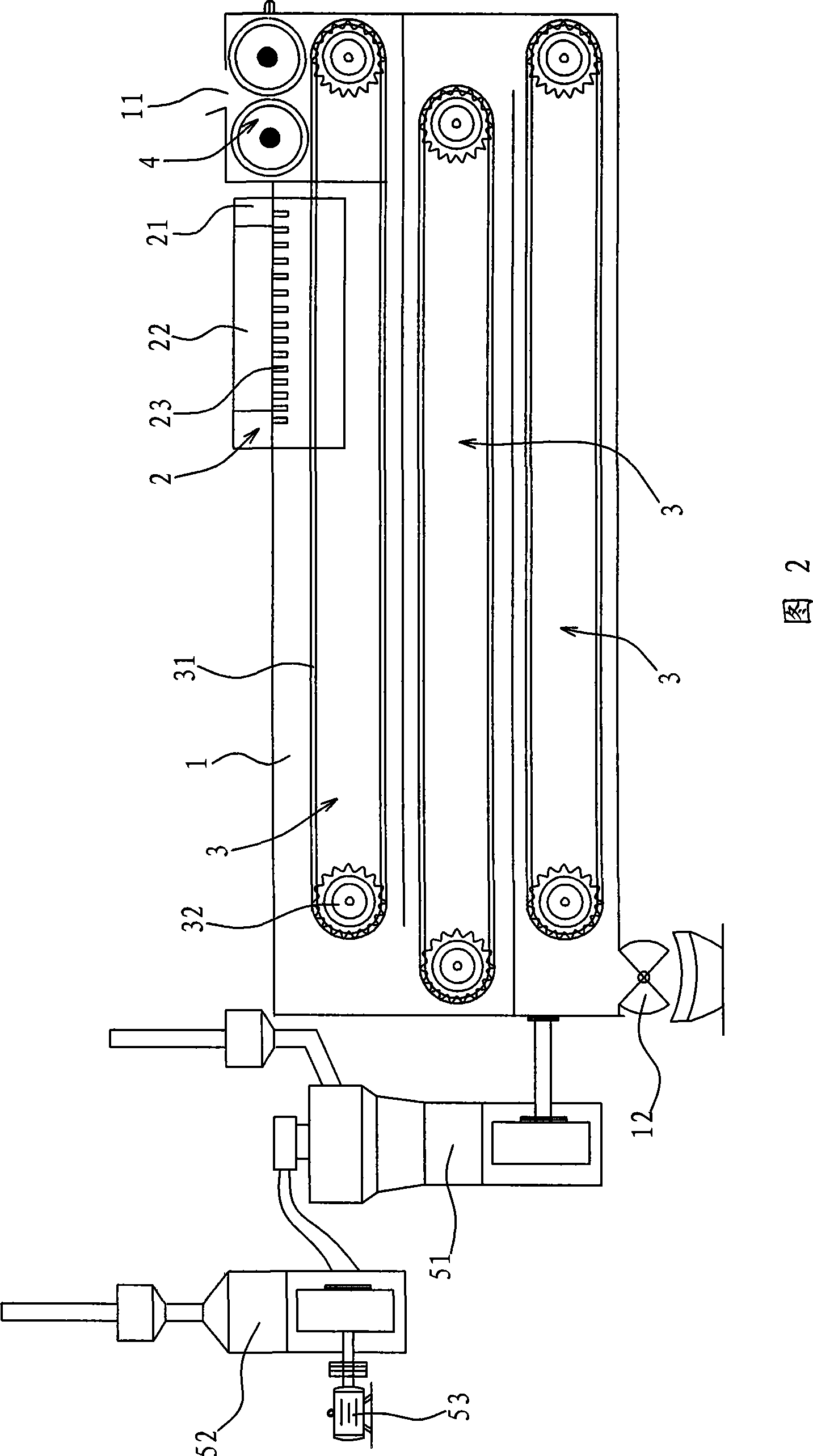

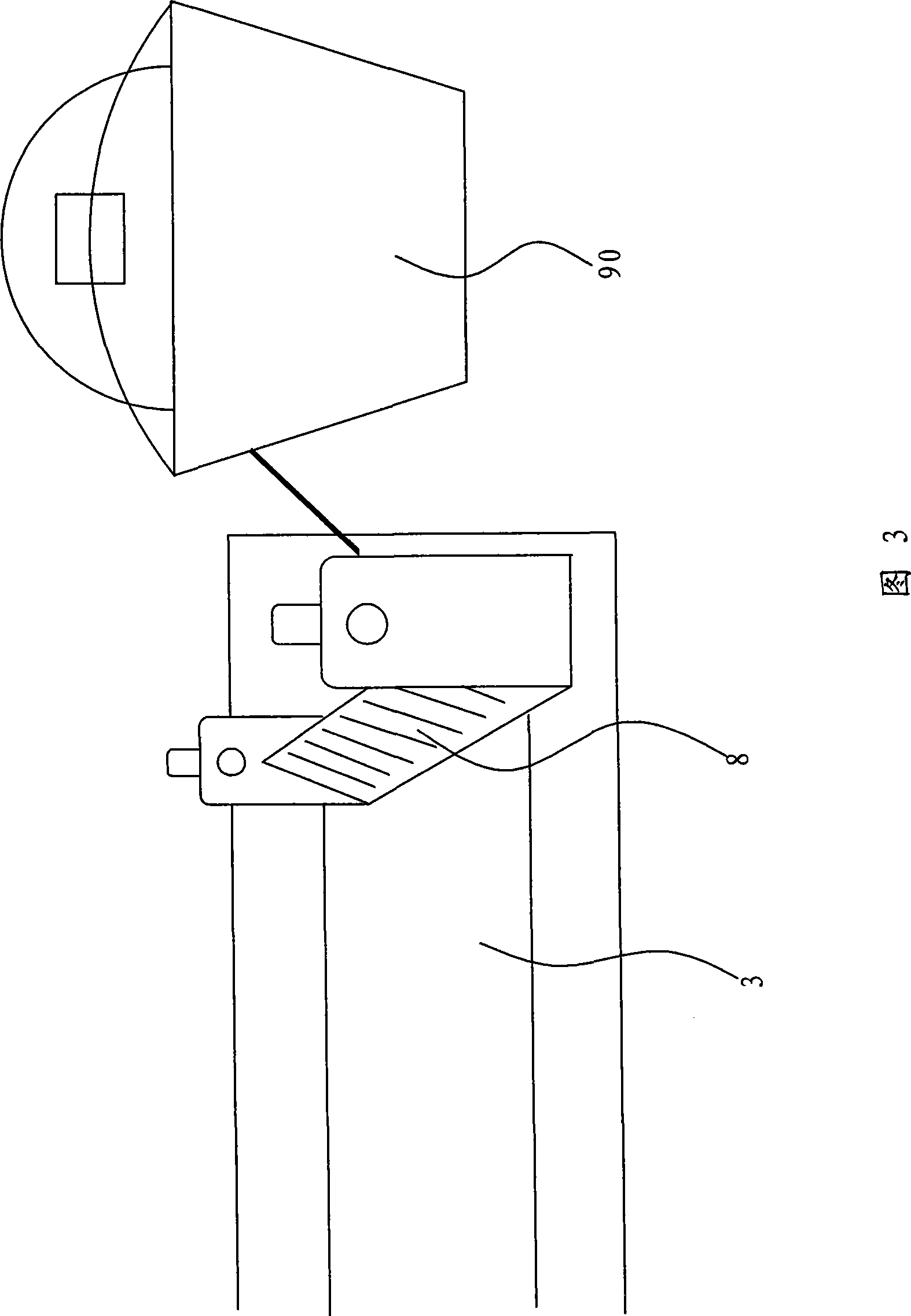

[0019] Referring to Fig. 1, according to a preferred embodiment provided by the present invention, it includes a box body 1, a heating device 2 installed in the box body 1 and a drying conveyor belt 3, and the box body 1 is provided with a feeding port 11 and a discharge port 12, the sludge extrusion drum 4 is installed at the feed port 11. In the present invention, a sludge extruding roller 4 is arranged at the feeding port of the box body 1, and the blocky sludge entering the box body 1 is squeezed by the sludge extruding roller 4, and the sludge is extruded into thin slices. This flaky sludge is good for drying, which can greatly reduce the drying time, thereby shortening the length of the entire drying equipment. At the same time, the sludge extruding drum 4 can extrude a part of excess moisture in the sludge, which is also beneficial to subsequent drying.

[0020] Referring to FIG. 1 , in the above-mentioned embodiments of the present invention, the box body 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com