LED light source structure

A technology of LED light source and LED chip, which is applied in the direction of light source, point light source, light source fixation, etc. It can solve the problems of increasing the cost of LED street lamps, limited irradiation range, and poor brightness uniformity, so as to improve the uniformity of illumination, reduce production costs, The effect of improving the light output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

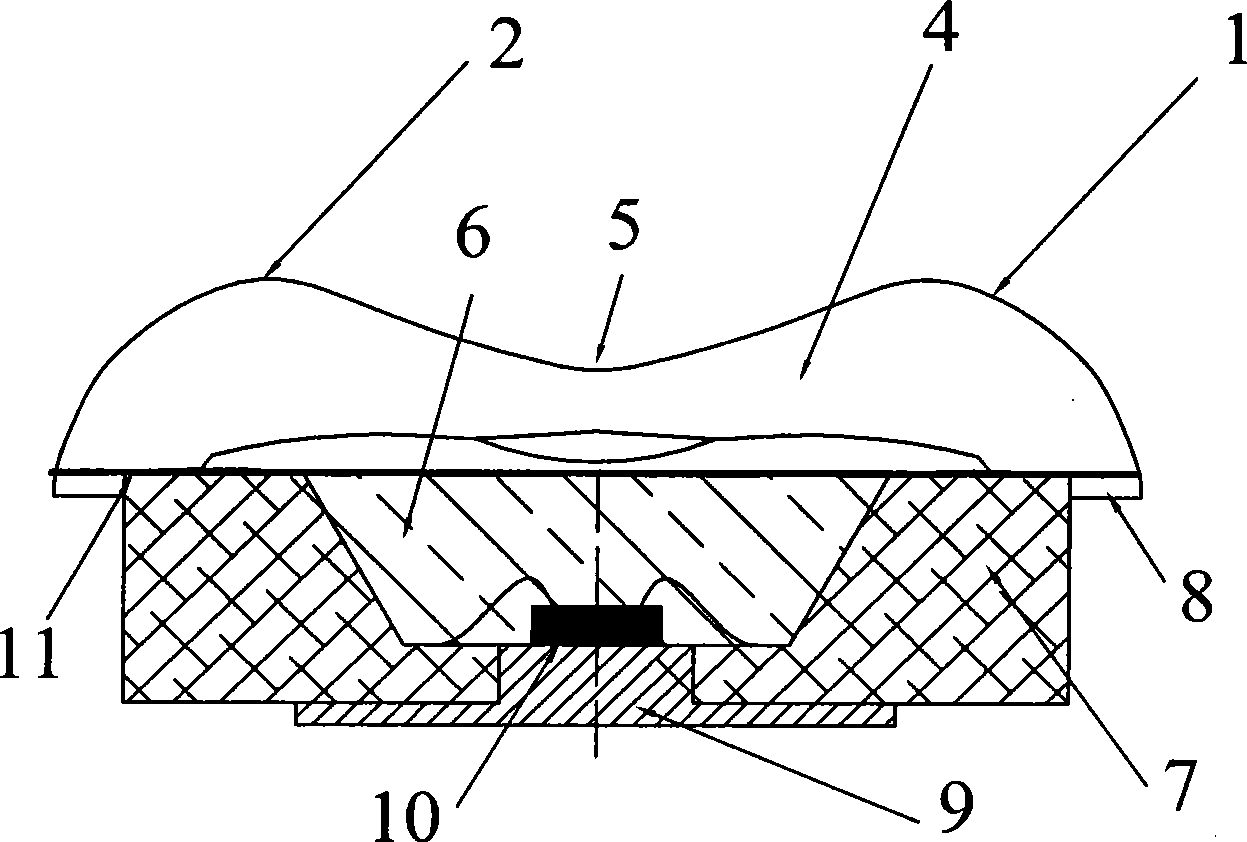

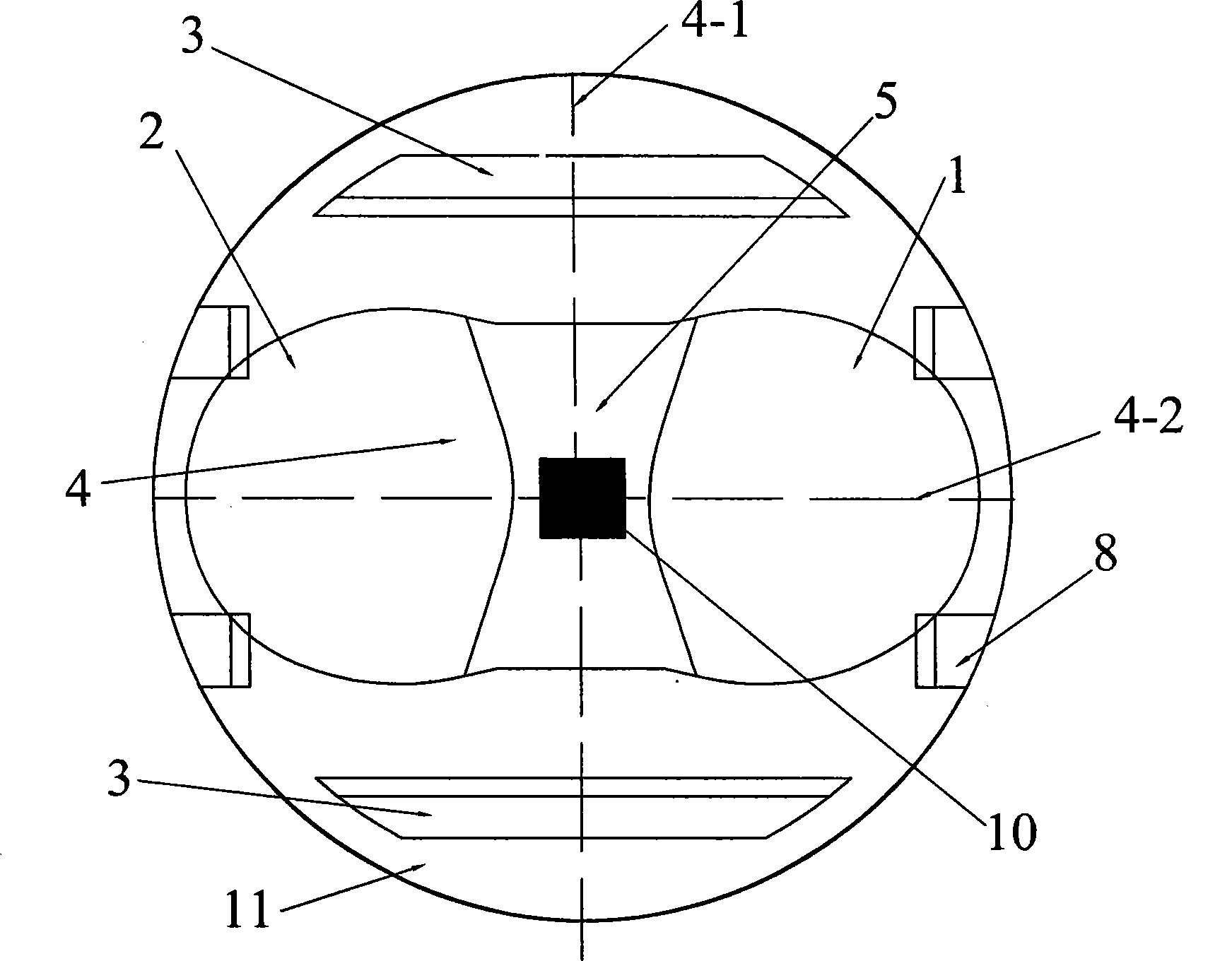

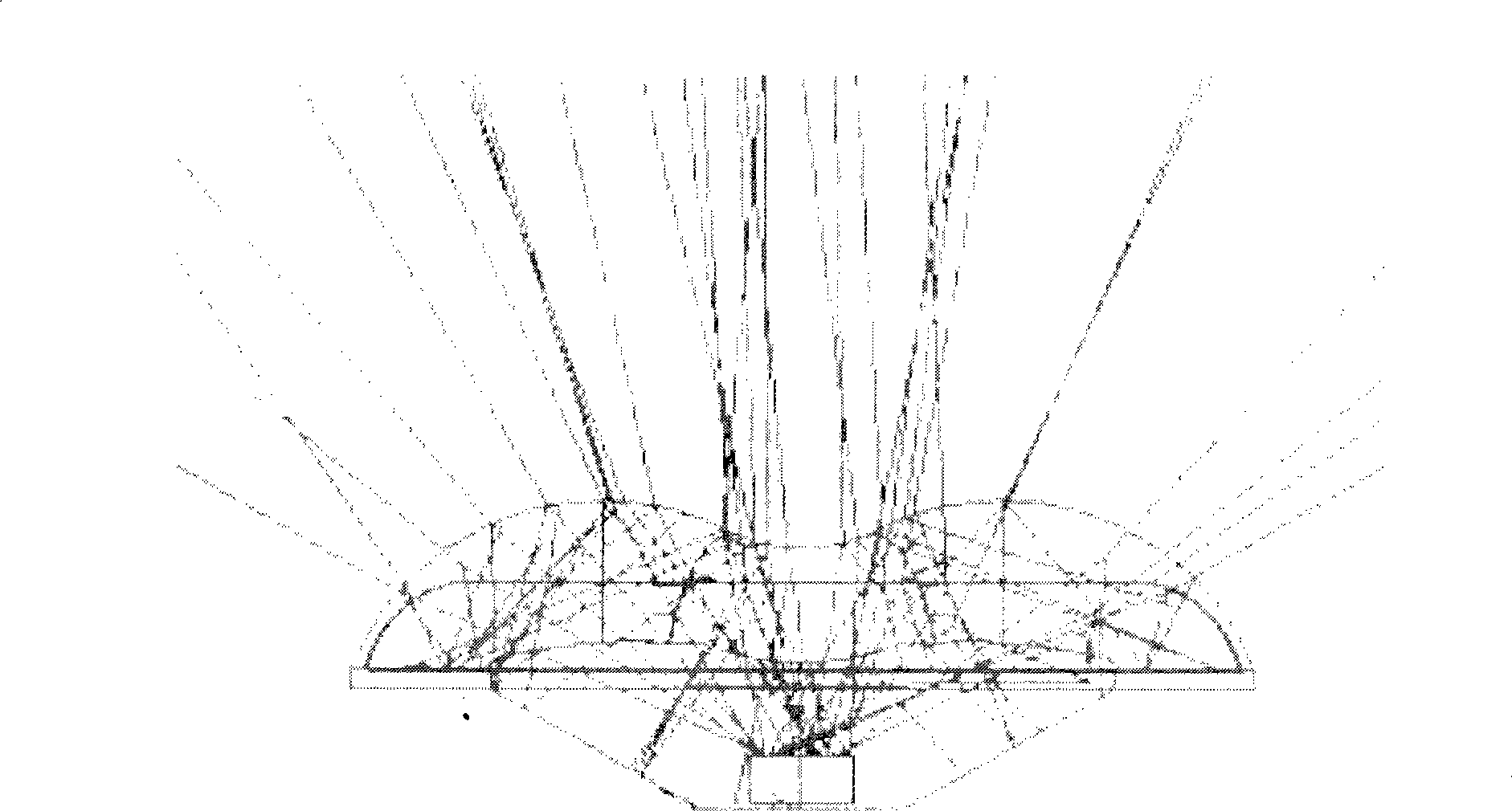

[0017] Such as figure 1 , 2 As shown, the lens 4 made of silicone resin material is installed on the smooth upper plane 11 of the heat-conducting bracket 7, the bracket 7 is injection molded by high-temperature nylon material, the bottom of the lens 4 is flat with the upper plane 11 of the bracket 7, and the lens 4 passes through 4 A boss 8 is closely bonded to the support 7. The LED chip 10 is packaged in the cavity formed by the bracket 7 and the lens 4 . A reflection cup 6 is fixed in the cavity of the bracket 7, and the reflection cup 6 is filled with a mixture of silica gel and fluorescent powder with a refractive index of 1.53, and the mixture is cured and formed in advance. The LED chip 10 is located at the center of the bottom of the reflective cup 6 and is fixed on the heat conduction seat 9 at the bottom of the support 7 .

[0018] The upper surface of the lens 4 is two connected semi-ellipsoids or hemispherical structures, the semi-ellipsoid or hemispherical stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com