Device for grinding cutting blade of automatic cutting device

A technology of a grinding device and a cutting knife, which is applied in metal processing and other directions, can solve the problems of reduced cutting precision, easy deposition, durability problems, etc., and achieves the effect of maintaining cutting precision, improving cutting speed, and high cutting precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

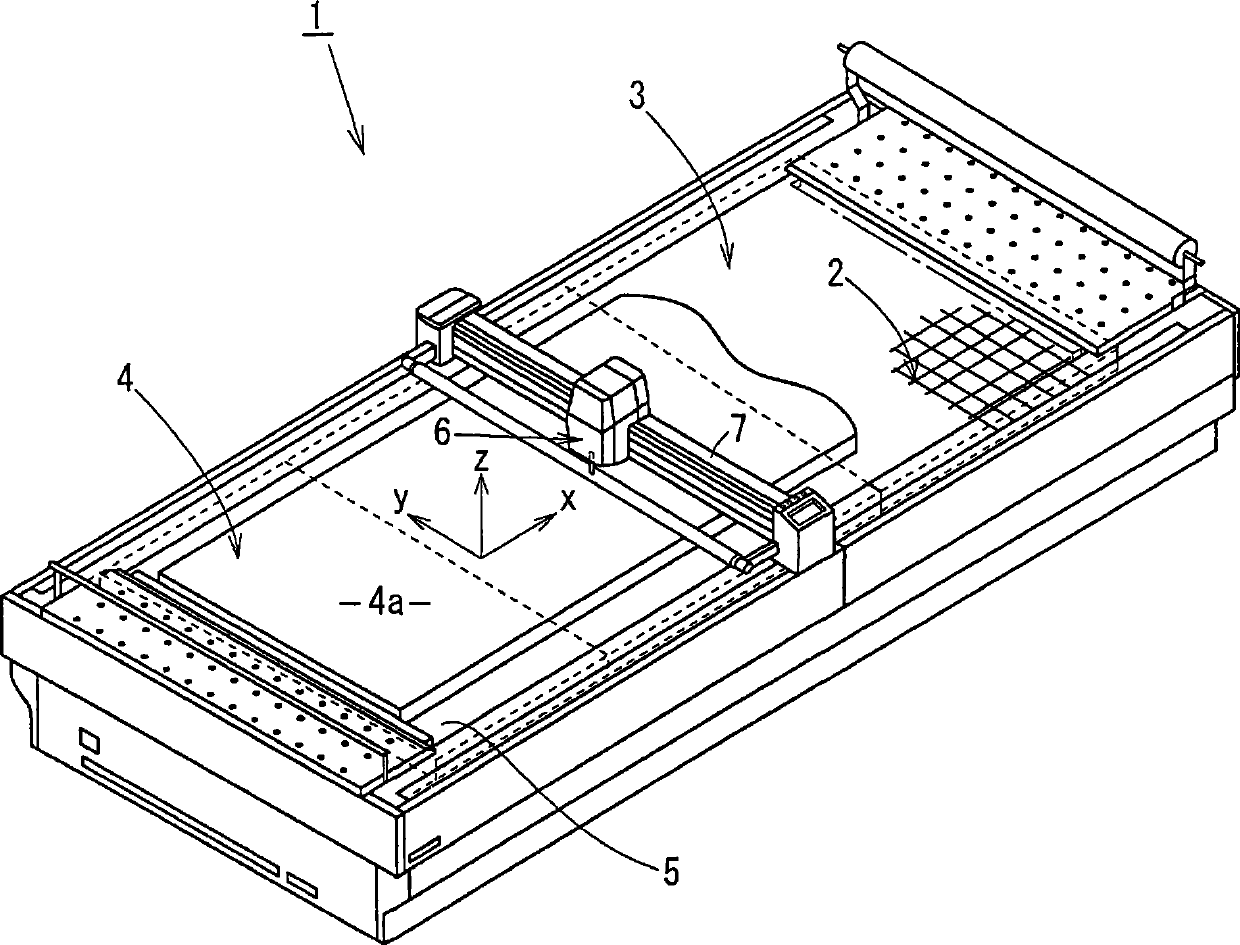

[0032] figure 1 It is the overall perspective view of the automatic cutting machine, and the label 1 in the figure represents the automatic cutting machine as a whole.

[0033] In this automatic cutting machine (referred to as a cutting machine) 1, a plurality of sheet materials 4 are stacked on a flat support surface (cutting table) 3 composed of a plurality of bristle brushes 2, which are gray cloths such as clothes, and airtight The thin sheet 5 is covered, so that the thin sheet material 4 is adsorbed and fixed on the support surface 3 .

[0034] A cutting head 6 for cutting these sheet materials 4 into a predetermined shape is movably arranged in the width direction (Y-axis direction) of the cutting machine 1 on a beam 7 that moves in the longitudinal direction (X-axis direction) of the cutting machine 1. .

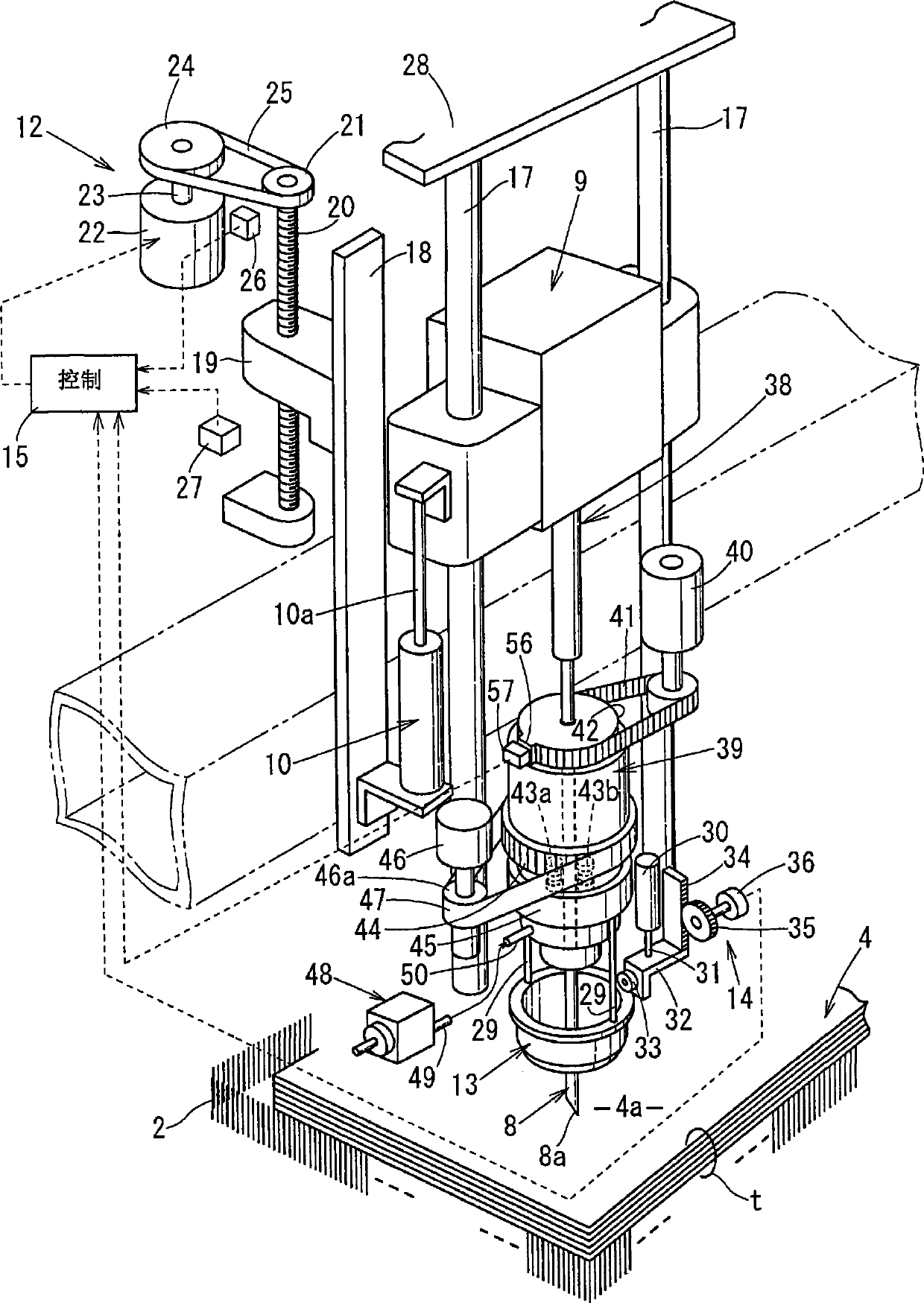

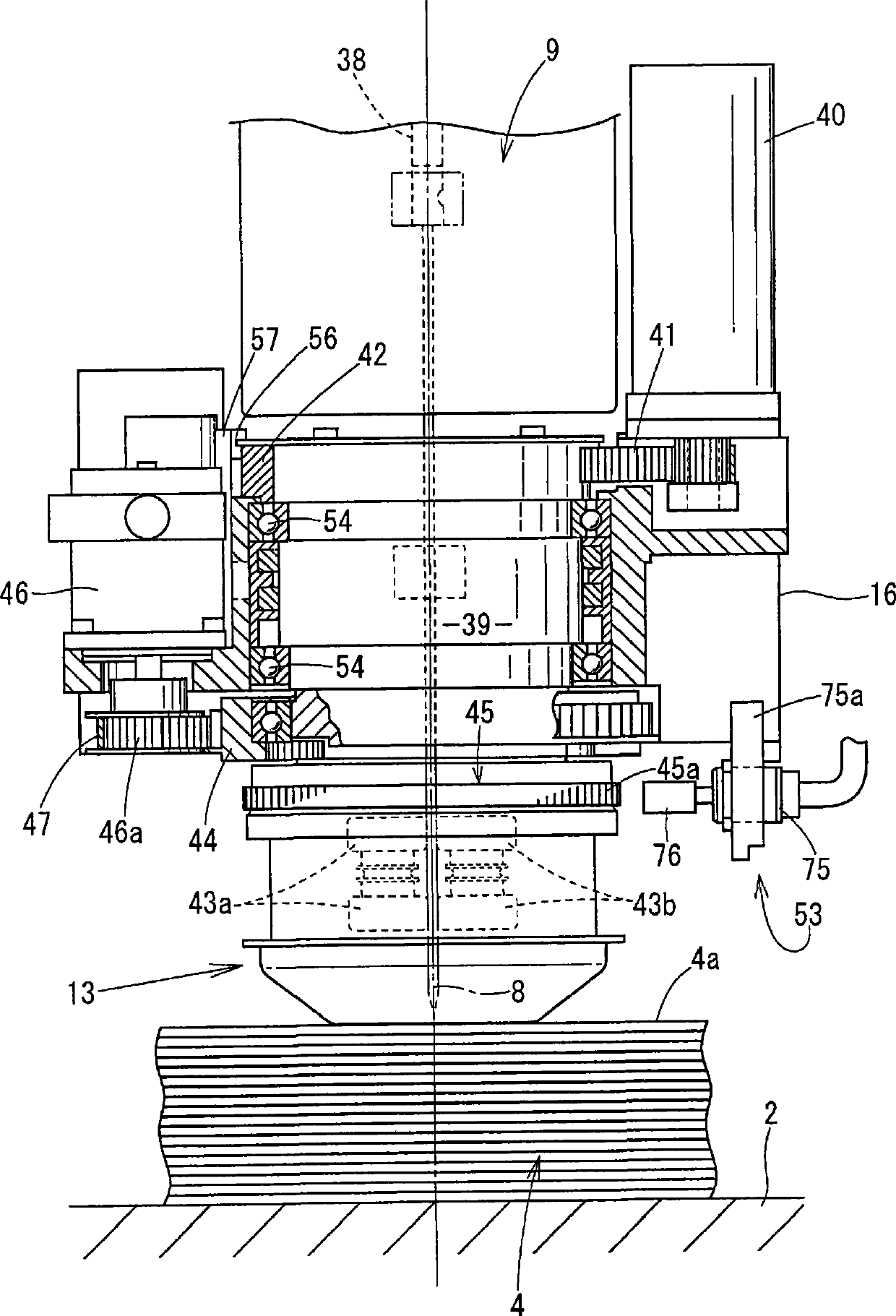

[0035] The basic composition of cutting head 6 is as follows: figure 2 Shown, comprise: cutting blade 8; Utilize the cutting blade vibration motor (not shown) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com